Geotextile Landscape Fabric for Railway - PP Waterproof Geotextile

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Non Woven Geotextile Introduction:

Nonwoven geotextiles are manufactured from the extrusion of polypropylene fibres which are then laid down on a manufacturing "bed" and then needle punched to entangle the fibres such that a dimensionally stable product is formed. Some additional thermal treatment is then applied to further improve the strength of the geotextile. Because of this manufacturing process non-woven geotextiles are generally best used in applications of drainage, filtration and protection

| NO. | Specifications and indicators | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | Remark |

| 1 | Deviation of mass per unit area2)(%) | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

| 2 | Thickness (mm≥) | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3 | 3.3 | 3.6 | 4.1 | 5 | |

| 3 | Amplitude-deviation(%) | -0.5 | |||||||||||

| 4 | Breaking strength(KN/m≥) | 2.5 | 4.5 | 6.5 | 8 | 9.5 | 11 | 12.5 | 14 | 16 | 19 | 25 | LD/MD |

| 5 | Elongation at break(%) | 25-100 | LD/MD | ||||||||||

| 6 | CBR burst strength(KN≥) | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4 | |

| 7 | Equivalent aperture090(095)(mm) | 0.07-0.2 | |||||||||||

| 8 | Vertical permeability coefficient(cm/s) | K×(10-1-10-3) | K=1.0-9.9 | ||||||||||

| 9 | Tearing strength(KN≥) | 0.08 | 0.12 | 0.16 | 0.2 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | LD/MD |

| Note: TD=transverse direction LD=longitudinal direction | |||||||||||||

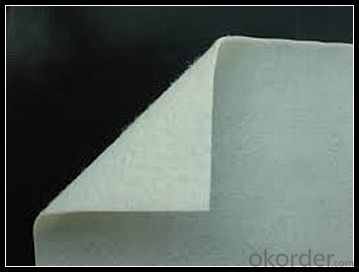

Photos:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles improve the performance of geofabrics?

- Geotextiles improve the performance of geofabrics by providing additional strength and stability to the materials. They act as reinforcement layers, preventing the soil particles from shifting or migrating, thus enhancing the overall durability and functionality of geofabrics in various civil engineering applications.

- Q: What are the different functions of geotextiles in geoenvironmental engineering?

- Geotextiles serve various functions in geoenvironmental engineering, including erosion control, soil stabilization, drainage, filtration, and reinforcement. These materials prevent soil erosion by acting as a barrier against water flow and wind forces. They also stabilize soil by improving its mechanical properties, preventing soil movement and settlement. Geotextiles facilitate drainage by allowing water to pass through while retaining soil particles. They serve as a filtration layer, separating different soil layers and preventing the migration of fine particles. Additionally, geotextiles are used for reinforcement purposes, enhancing the strength and load-bearing capacity of soil structures.

- Q: The difference between short wire geotextile and filament geotextile

- Geotextile is a collectively, he includes filament geotextile, short wire geotextile, woven geotextile, woven geotextile, hot pressed nonwovens. Polyester filament geotextile color is mainly white, green. Gray two categories. The length of the fiber is greater than 4.5 cm. Strong strength is very high. Looks very good distinction.

- Q: Sng400-2.5gb / t-1998 geotextile is what the specifications

- SNG400-2.5 refers to the national standard polyester staple acupuncture non-woven geotextile 400g / ㎡, width 2.5m. The standard code for the GB / T-1998 staple fiber nonwoven geotextile is generally the SNG / (1) (2) / (3) - (4) / (5). (1) that the use of raw materials fiber code: PET-polyester, PP-polypropylene, PA-nylon, PV-vinylon, PE-Ethylene (conventional polyester are generally vacant omitted code) (2) that polyester staple fiber non-woven Geotextile per unit area weight. (3) that the composite products in the polyester staple fiber non-woven geotextile weight per unit area, non-composite product vacancies. (4) width, expressed in meters (5) production department number: can express the product more specific characteristics, functions, varieties, sequences, etc., the general vacancy. For example, 2.5m wide 400g / ㎡ polyester staple fiber non-woven geotextile representation of the method can be SNG / PET400-2.5, can also be expressed as SNG400-2.5

- Q: What are the geotechnical test test items for highway engineering? The

- The main inspection items are: ① Tensile strength: In the tensile test, the maximum tensile stress of the specimen up to the fracture is the tensile strength, which is called tensile strength in academia. ② elongation: elongation, that is, the percentage of the ratio of the total deformation to the length of the original gauge after the tensile fracture of the specimen. ③ tear strength: it is a thin film or thin film tear resistance of a test method defined in a term. This method is a tear test performed on a special testing machine with a specimen with a predetermined gap. ④ bursting strength ⑤ thickness ⑥ per unit area quality ⑦ permeability coefficient: permeability coefficient, also known as hydraulic conductivity. In an isotropic medium, it is defined as the unit flow rate per unit of hydraulic gradient, indicating the ease with which the fluid passes through the pore skeleton.

- Q: Geotextile between the use of lap, lap width is not less than?

- Lap width is generally 0.2M or more.

- Q: What are the different geotextile reinforcement techniques?

- Some of the different geotextile reinforcement techniques include geotextile fabrics, geogrids, geocells, and geocomposites. Geotextile fabrics are permeable fabrics made from synthetic materials and are used to stabilize soil and prevent erosion. Geogrids are high-strength materials that are used to enhance the stability of soil by providing tensile reinforcement. Geocells are three-dimensional honeycomb-like structures made from geotextile materials and are used for soil stabilization and erosion control. Geocomposites are combination products that consist of different geotextile materials and are used for various reinforcement applications, such as drainage, filtration, and separation.

- Q: Are geotextiles resistant to biological degradation?

- Yes, geotextiles are generally resistant to biological degradation.

- Q: Can geotextiles be used in shoreline restoration projects?

- Yes, geotextiles can be used in shoreline restoration projects. Geotextiles are commonly used to stabilize and protect soils in various engineering applications. In shoreline restoration, they can help control erosion, stabilize slopes, promote vegetation growth, and protect against wave action.

- Q: Are geotextiles resistant to puncture?

- Yes, geotextiles are generally resistant to puncture due to their strong and durable construction.

Send your message to us

Geotextile Landscape Fabric for Railway - PP Waterproof Geotextile

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords