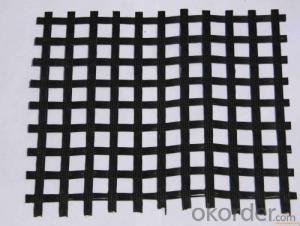

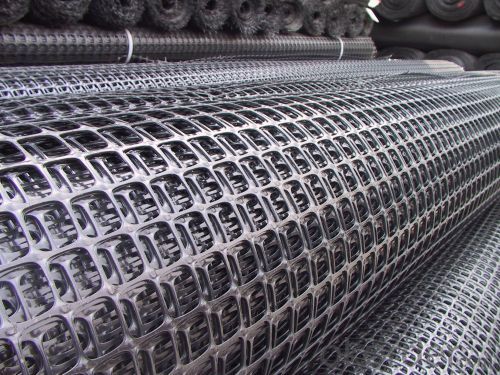

Nysdot Approved PP Plastic Biaxial Geogrid by Manufactory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Biaxial PP Geogrid,

Biaxial geogrids are made of macromolecule polymer by the process of being stretched out, formed into lamella, punched regularly and then longitudinal and transverse elongated. They have much higher longitudinal and transverse tensile strength. These structures can supply alinking system to soil, which be used broadly to enable the permanent bearing capacity of roadbed.

Biaxial Geogrid Features:

(1)High intension,high tenacity,high occlusive force with soil or gravel,erosion-resistant,

water drainage,light weigth.

(2)Reinforce soft soil roadbed,rib side slope of embankment,enhance isolation,

inhibit ground deformation,prevent crack by reflection,increase strength of roadbed.

The main function as follows:

1.Reinforce the base, efficiently allot and diffuse the pressure, prolong the using time;

2.Increase the load-bearing capabilities;

3.Avoid the base becoming deformed and creaking (for the material washed away);

4.Improve the endure, reduce the pressure of the blocking wall, save the cost, prolong the using time, and reduce the servicing;

5.Reduce the crook and track, delay 3-9 times of the appearance of the crack, reduce 36% of the thickness of the structure by adding the geogrid into the base and cover of the road,

6.Be applicable of all kinds of soil;

7.Be easy to construct and reduce the cost.

FAQ:

Q: What is your MOQ?

A: Normally, 1000 m2 per order.

Q: What is your delivery time? Can we have it sooner?

A: 2 days for sample, 3-5 days against 1x40HQ

Q: What is your payment terms?

A: T/T, Paypal (3% surcharge), Western Union or 30% deposit 70% L/C.

- Q: Glass fiber grille is not geogrid

- Geogrid includes plastic geogrid, steel plastic geogrid, fiberglass geogrid

- Q: Can geogrids be used in ground improvement techniques?

- Yes, geogrids can be used in ground improvement techniques. Geogrids are commonly used in various ground improvement methods such as soil reinforcement, stabilization, and erosion control. They are effective in enhancing the strength and stability of weak soils, providing increased load-bearing capacity, reducing settlement, and preventing soil erosion. Geogrids can be installed horizontally or vertically depending on the specific ground improvement requirements.

- Q: Geosynthetic materials for flood control materials

- The aging rate of geotextile exposed to sunlight is very fast, which can only be used for 1 years at most. However, the aging speed will be much slower when buried in soil or under water. At present, the aging speed of polypropylene fabric is very fast, the aging rate of polyester and polyethylene fabric is slow, and the difference is nearly L times. For the same kind of geosynthetics, light aging fast, slow aging aging dark, flat, thin, round wire, thick slow aging. Geomembrane is generally divided into two categories of asphalt and polymer. Each of the two classes has no reinforcement and reinforcement. The most commonly used polymer geomembrane is PVC, CPE, CB, HDPE, CSPE, etc..

- Q: Can geogrids be used in railway track stabilization?

- Yes, geogrids can be used in railway track stabilization. Geogrids are commonly used in civil engineering projects to improve soil stability, reinforce weak subgrades, and minimize lateral movement. In railway track stabilization, geogrids can be installed beneath the ballast layer to enhance load distribution, reduce track settlement, and increase the overall strength of the track system.

- Q: Are geogrids suitable for use in soil reinforcement for pipeline river crossings?

- Yes, geogrids are suitable for use in soil reinforcement for pipeline river crossings. Geogrids offer excellent soil stabilization and reinforcement properties, providing enhanced tensile strength and load-bearing capacity. They are particularly effective in areas with challenging soil conditions or high water flow rates. Geogrids can effectively distribute the loads from the pipeline, prevent soil erosion, and ensure long-term stability, making them a reliable choice for reinforcing soil in pipeline river crossings.

- Q: Asked the retaining wall engineering grille mistook polypropylene as high density polyethylene, how to do? Is there any remedy?

- What is wrong with the polypropylene in the geogrid in the retaining wall of the road? Performance will not be affected? Is there any remedy?

- Q: What is the typical width of a geogrid roll?

- The typical width of a geogrid roll ranges from 4 to 16 feet, although some manufacturers may offer wider options as well.

- Q: What are the design considerations for geogrid-reinforced pavements on soft soils?

- Some of the important design considerations for geogrid-reinforced pavements on soft soils include assessing the soil properties, determining the appropriate geogrid type and placement, considering the load-bearing capacity and stability requirements, evaluating the potential for differential settlement, accounting for construction and maintenance factors, and ensuring proper drainage to prevent water accumulation.

- Q: What is the effect of strain rate on geogrid behavior?

- The effect of strain rate on geogrid behavior is that it can significantly impact the mechanical properties and performance of the geogrid. At higher strain rates, the geogrid may exhibit increased stiffness and strength due to the rate-dependent nature of its materials. This means that the geogrid can better resist deformations and provide enhanced stability under dynamic loading conditions. However, at extremely high strain rates, the geogrid may experience reduced performance and even failure due to excessive stress concentrations and insufficient time for dissipation of energy. Thus, understanding and considering the strain rate is crucial in designing and applying geogrids for different applications.

- Q: Are geogrids resistant to hydrocarbons?

- Yes, geogrids are generally resistant to hydrocarbons.

Send your message to us

Nysdot Approved PP Plastic Biaxial Geogrid by Manufactory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords