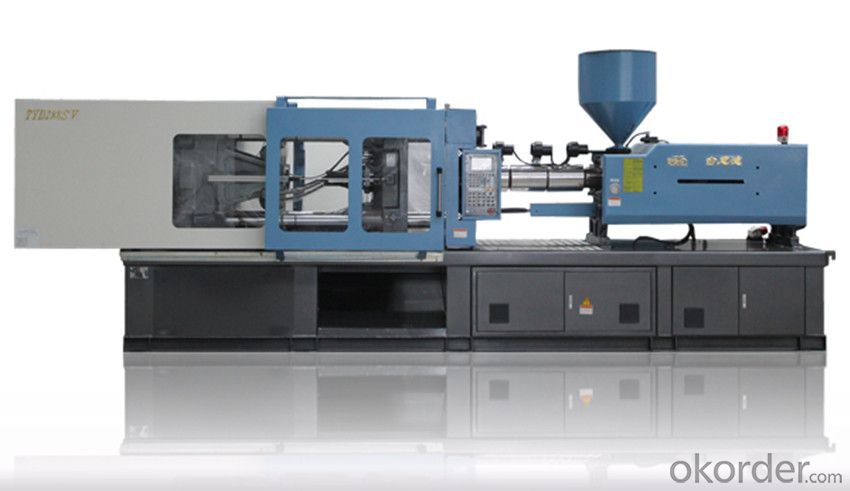

pp disposable food box plastic injection molding machine for thin wall products

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 40 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

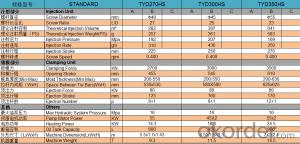

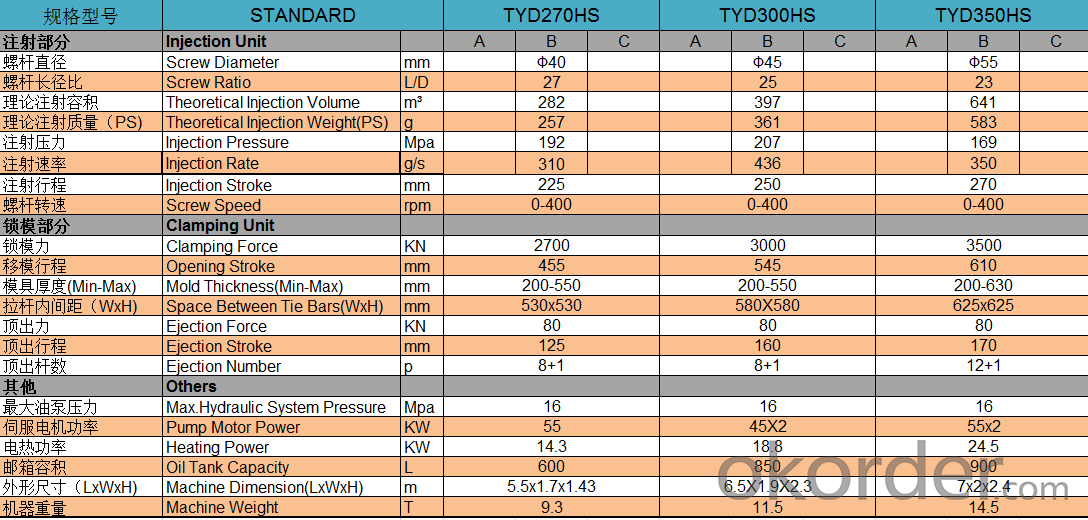

THIN WALL PRODUCTS SPECIAL MACHINE

PP DISPOSABLE FOOD BOX

3 MACHINE WITH SPACIAL SCREWS for your reference

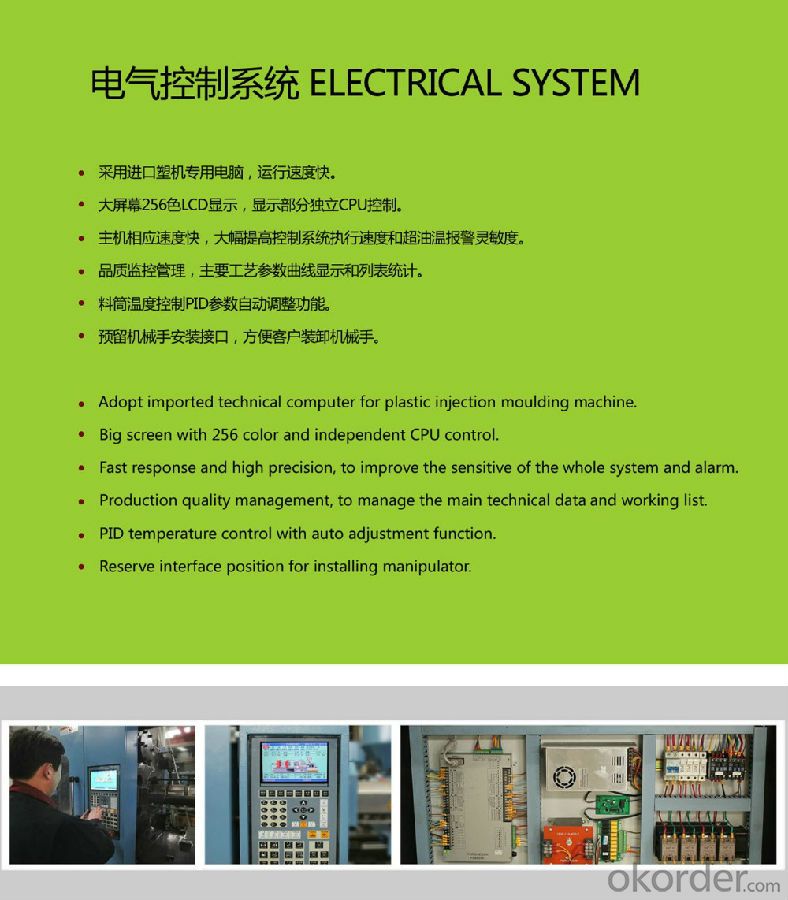

our technical advantage

our packing:

Fine package on pallet. In case of the size and weight requirment, it will be loaded in seperated containers.

Our Services

1. Our manufactory team will help you to choose the TYD machines to match your production demand

2. We apply the OEM service to meet your production requirment

3. Our after-sale service will help you to maintain the machine in proper condition

Company Information

our factory is one of the professional plastic injection molding machinery manufactury in China

The characteristics of the machines are high efficiency and energy saving, the spec are from 50 grams to 20000 grams.

We have 100 sales and service facilities were founded in China and overseas market.

Up to now, our products have sold in Brazil, Pakistan, Russia and other places.

We have passed the ISO 9001:2008 and CE certification.

The main parts of the machine come from Germany, Italy, Japan, Taiwan and other countries.

FAQ

Q. How to choose the TYD injection molding machine?

A. It based on the mold size and mold stroke according to products weight and dimension, wall thickness, properly clamping force and combined with the injection pressure. Our work team will help you to make the good choice if you can apply the products spec.

Q. Do you OEM?

A. Yes, our OEM team would like to work with you.

Q. where is your factory location?

A. we are located in Zhoushan seacost City which is near the Shanghai and Ningbo city. your are welcome to visit our factory.

- Q: What is an injection molding machine?

- Injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment.Working principle:The working principle of injection molding machine and injection syringe with similar, it is the use of screw (or piston) thrust, the plasticizing good molten state (i.e. viscous flow) plastic injected into the mold cavity closed good after curing stereotypesmade the process of the products. Injection molding is a cycle process, each cycle mainly include: quantitative feeding - melt plasticization - pressure, injection - filling mold cooling - die opening pieces. Take out the plastic parts and then close the die for the next cycle.

- Q: Injection machine profile size

- The size of the nozzle is confirmed:When you write sizes, you often write "M45*3*", which means "diameter * tooth pitch", and the length varies from 50 to 200 (depending on demand)

- Q: What is the function of the temperature control box of the injection molding machine? Thank you

- Control the temperature and see where the line meets where the temperature is controlled

- Q: Every time the adhesive is stable, the glue is basically stable, but about 100 of the 2-3 die will not be in place, for example, the 50MM will stop

- Whether the travel switch is in bad contact or that the sealing ring and the wear resistant hydraulic oil are used for a long time and need to be replaced

- Q: Not computer, there is a proportional current. The whole machine has no hydraulic operation and the pressure gauge is zero.

- 2 、 injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment. It is divided into vertical, horizontal and all electric type. The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity.

- Q: How to repair the injection machine?

- Common faults in the use of injection molding machines and solutions are as follows:Part 1: Problems and treatment methods of mould locking parts:(1) not locking dies:Handling method: 1) check the front travel switch of safety door and repair it.2) check the 24V5A power in the electric box, replace the insurance and the power box.3): check whether the spool is stuck, cleaning the spool.4): check whether the output of the I/O board, the solenoid valve is charged.5): check whether the hydraulic safety switch is closed, whether the mechanical lock rod is opened or not.(two) the opening and closing of the die machine:Handling method: 1) check whether the lubricating oil pipe is broken or, if so, reconnect the tubing.2): small amount of lubricating oil, lubricating oil amount increase, 50 die once or manually add oil and lubricating oil.3): clamping force, check whether the mold needs large clamping force, lower the clamping force.4): the current fluctuation of the amplifier board, check whether the current parameters meet the acceptance criteria, re adjust the current value.5): parallelism error indicator check head board parallelism is greater than the acceptance criteria; adjust the parallelism.

- Q: I want to know the injection speed of injection molding machine. What is the specific unit?

- For example: 90T injection molding machine, screw diameter 28mm, its maximum speed is 86cm3/s, if the parameter set a speed of 90, then 86cm3/s is multiplied by 90%, this is the actual speed of injection.If you want to know the maximum speed of your injection machine, you have to check the instructions and specifications of the machine.

- Q: What kind of after-sales service, which friends know to introduce?

- The best thing is the company's low pressure injection molding machine, and many famous brands are looking for them to process low voltage injection molding machines, such as apple, Microsoft, and the United states.

- Q: Injection molding machine pressure, speed, back pressure unit is what and their relations with other international units

- Pressure injection molding machine, we often talk about the pressure, strictly speaking, the pressure is equivalent to the middle school, which bear the force per unit area, the international regulations, under 1N in the area of 1 square meters (Newton) on the pressure of 1Pa (Pascal), as long as know the multiple relation, it is easy to obtain the pressure (strong the conversion unit):1m=100cm=1000mm1kg = 10N1M (megabit, million) Pa=1MPa=1000k (1000) Pa=1000000PaSo 1MPa=10kg/cm^2=1N/mm^2We often use international non legal units of measurement: 1bar=10^5Pa=1kg/cm^2=0.1MPa (bar) and 1Torr=133Pa (Torr)The pressure gauge of the injection molding machine, the most used is MPa, bar, kgf/cm^2 unit, need to be reminded that, behind the two units is not our statutory units of measurement, but the world especially Europe and the United States is often used, because many components of the injection molding machine for imported components, including the pressure gauge, so we will often see illegal dial pressure gauge measurement units.In the injection molding machine, the injection molding machine pressure and back pressure unit is MPa, speed (actually refers to injection rate), the unit is g/s, or cm^3/s

- Q: What are the injection molding machine brands in China?

- Can refer to modern plastic injection molding machine brand surveyIn recent years, the rapid development of China's plastics industry has greatly improved the injection molding machine industry. With Europe, the United States, Japan, Korea and many other internationally renowned injection molding machine brand access, as well as the rapid rise of China's injection molding machine enterprises, the market competition is becoming increasingly fierce. In order to help you understand the user China injection molding machine current demand psychology, demand status and dynamic demand, "PT" magazine on the basis of modern plastic Vogel industry media reader huge data resources at home and abroad, 54 injection molding machine brand, in the reader investigation activities brand demand. To improve the accuracy and objectivity of the survey, the survey issued a total of 3000 questionnaires, the main application areas covered by the injection molding machine, including packaging, automotive, household appliances, electronic communication equipment and medical equipment industries. A total of 355 valid questionnaires were received, of which more than 60% of respondents had equipment procurement decision-making rights or advice in the enterprise.

Send your message to us

pp disposable food box plastic injection molding machine for thin wall products

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 40 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords