Mirafi Non Woven Geotextile PP Biaxial Geogrid

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

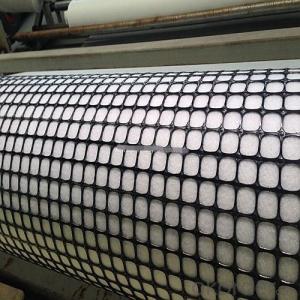

| Packaging Detail: | rolls |

| Delivery Detail: | 10days onet 40FCL |

Specifications

materials:PP

roll size:4m*50m

tensile strength:15KN/m-40KN/m

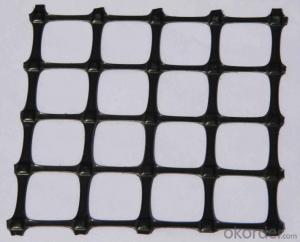

pp biaxial geogrid

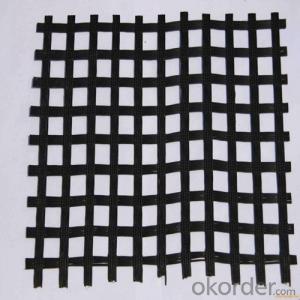

To lay the geogrid in the backfill soil can increase the shearing strength and the whole character in middle terms, reduce the mid-term filling quantity, make the soft base more convenient, lower the construction cost.

When used in the dam design, it can be as the muscle structure to improve the bearing distortion performance of the dam to avoid breaking

materials:PP

roll size:4m*50m

tensile strength:15KN/m-40KN/m

PP biaxial geogrid

Technical data

Item | Art. No. | PLB010301 | PLB010302 | PLB010303 | PLB010304 | PLB010305 |

Specs | TGSG15-15 | TGSG20-20 | TGSG30-30 | TGSG40-40 | TGSG45-45 | |

Unit weight,g/m2 | 300±30 | 330±30 | 400±40 | 500±50 | 550±50 | |

Width,m | 4.0+0.2/-0 | |||||

Tensile strength(MD), kN/m≥ | 15 | 20 | 30 | 40 | 45 | |

Tensile strength (CD),kN/m≥ | 15 | 20 | 30 | 40 | 45 | |

Elongation(MD),%≤ | 13 | |||||

Elongation(CD),%≤ | 16 | |||||

Tensile strength at 2% strain(MD),kN/m≥ | 5 | 7 | 10.5 | 14 | 16 | |

Tensile strength at 2% strain(CD),kN/m≥ | 5 | 7 | 10.5 | 14 | 16 | |

Tensile strength at 5% strain(MD),kN/m≥ | 7 | 14 | 21 | 28 | 32 | |

Tensile strength at 5% strain(CD),kN/m≥ | 7 | 14 | 21 | 28 | 32 | |

- Q: How do geotextiles affect construction site safety?

- Geotextiles play a crucial role in enhancing construction site safety by providing various benefits. Firstly, they act as a protective layer, preventing soil erosion and stabilizing the ground, which reduces the risks of landslides and collapses. Secondly, geotextiles can improve drainage by allowing water to flow through while retaining soil particles, preventing water accumulation that can lead to structural instability. Additionally, they enhance soil filtration, reducing the likelihood of contamination and pollution. Overall, geotextiles contribute to a safer construction site environment by mitigating potential hazards and ensuring the stability and integrity of the project.

- Q: What are the benefits of using geotextiles?

- Geotextiles offer numerous benefits such as erosion control, soil stabilization, and drainage improvement. They help prevent soil erosion by acting as a barrier and holding soil particles in place. Geotextiles also stabilize the soil by distributing load forces, thus enhancing the strength and durability of structures. Additionally, they promote efficient drainage, allowing water to pass through while retaining soil particles. Overall, geotextiles provide cost-effective solutions for various civil engineering and environmental applications.

- Q: Can geotextiles be used in sports field construction?

- Yes, geotextiles can be used in sports field construction. Geotextiles are often used as a separating layer between the soil and the drainage system, helping to prevent the mixing of different soil layers and promoting proper water drainage. Additionally, geotextiles can enhance the structural integrity of the field, provide reinforcement, and prevent the migration of fine particles within the soil.

- Q: Geotextile effect

- First, the drainage effect: polyester staple acupuncture geotextile has a good water conductivity, it can form a drainage channel within the soil, the soil structure of the excess liquid and gas efflux. Second, the role of contraction: When the water from the fine soil into the coarse soil layer, the use of polyester staple acupuncture geotextile good permeability and water permeability, so that water through, and effectively carrying soil particles, sand , Small stone, etc., in order to maintain the stability of soil and water engineering. Third, the isolation role: the use of polyester staple acupuncture geotextile with different physical properties of the building materials to isolate. So that two or more materials are not lost, not mixed, to maintain the overall structure and function of the material, so that the building capacity to enhance the capacity. Fourth, the role of puncture: and geomembrane combined into a composite waterproof impermeable material, play the role of anti-puncture. High tensile strength, good permeability, breathable properties, high temperature resistance, anti-freeze, anti-aging, corrosion-resistant, not moth-eaten. Polyester staple acupuncture geotextile is a widely used geosynthetics.

- Q: What kind of geotextile is used to repair the road?

- Call one three seven to understand three one two one two to ensure that the quality of price satisfaction

- Q: What is the role of geotextiles in road construction?

- Geotextiles play a crucial role in road construction by providing reinforcement, filtration, and separation functions. They are used to enhance the stability and longevity of roads by preventing the mixing of different soil layers, reducing erosion and maintaining proper drainage. Additionally, geotextiles help to distribute loads more evenly, preventing the formation of cracks and potholes, thus improving the overall performance and durability of the road.

- Q: Can geotextiles be used in the construction of sports fields?

- Yes, geotextiles can be used in the construction of sports fields. Geotextiles are commonly used as a separation and drainage layer under the playing surface to prevent soil contamination, promote proper water drainage, and enhance the stability and longevity of the field. Additionally, geotextiles can help control erosion and provide reinforcement to the subgrade, ensuring a durable and high-quality sports field.

- Q: How are geotextiles used in drainage systems?

- Geotextiles are used in drainage systems to enhance filtration and separation of soil particles, as well as to provide structural support and prevent clogging. They are often placed around perforated pipes or in trenches to allow water to flow through while preventing soil particles from entering the drainage system, ensuring its efficient operation and longevity.

- Q: How do geotextiles compare to traditional construction materials?

- Geotextiles are an innovative alternative to traditional construction materials. Unlike traditional materials such as concrete or asphalt, geotextiles offer numerous advantages. They are lightweight, easy to install, and highly flexible, allowing for efficient and cost-effective construction. Geotextiles also provide excellent erosion control, soil stabilization, and drainage capabilities. Furthermore, they are environmentally friendly, as they allow for natural filtration and groundwater recharge. Overall, geotextiles surpass traditional construction materials in terms of versatility, durability, and sustainability.

Send your message to us

Mirafi Non Woven Geotextile PP Biaxial Geogrid

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords