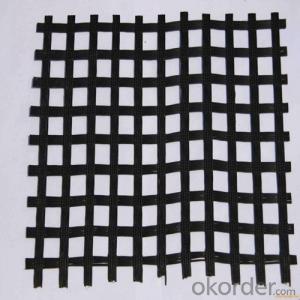

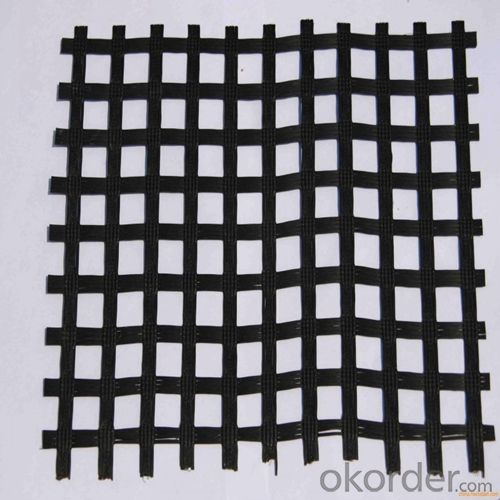

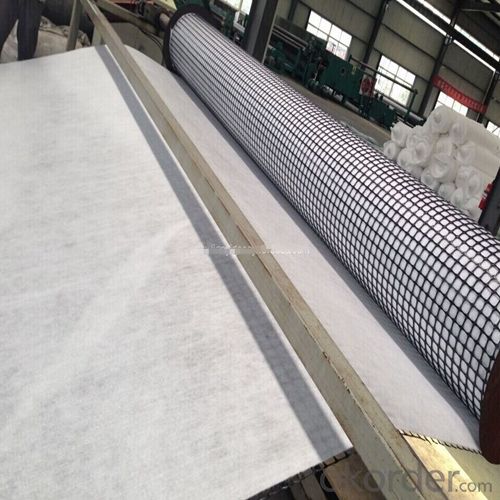

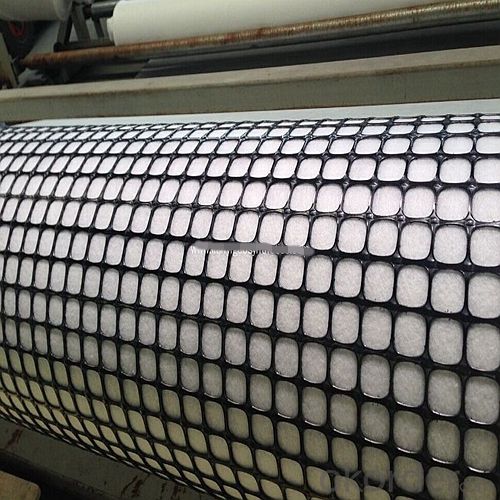

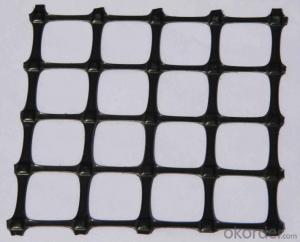

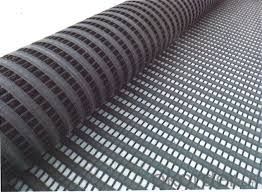

Mirafi Biaxial Polypropylene Geogrid with High Tensile Strength, Low Elongation, and Good Toughness

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Place of Origin:

China (Mainland)

Model Number:

Biaxial

Material:

Fiberglass

Tensile strength:

100kn

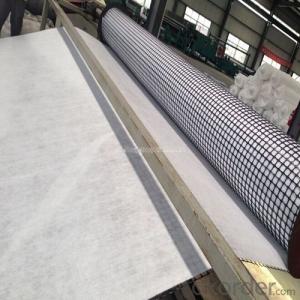

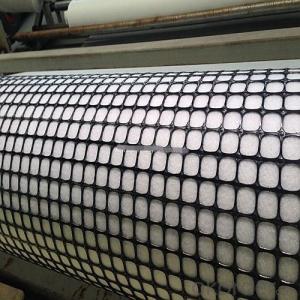

Roll Width:

3.95m

Roll length:

100 Meter

Porducts Description

Slopes and subgrades with rails are a serious problem in railroad construction. Under high

pressure the layers slide and deform consequently causing rail deformation, which requires

closing railroad segments for a long time. Geogrid application allows carrying out comlex

repair operations of the necessary road segment in shortest time (which is very essential

in transportation).

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Heap half a month later in the mound inside dug a tree tree hole, a heavy rain, a region which has two trees in the area of water, to several days of talent, which is normal, please expert advice, More

- Are you geotextile or composite film? Is your waterproofing layer ready? Do not leak?

- Q: Can geotextiles be used in erosion control mats?

- Yes, geotextiles can be used in erosion control mats. Geotextiles are often used as a component in erosion control mats to provide reinforcement and stabilization, helping to prevent soil erosion and promote vegetation growth.

- Q: How do geotextiles improve the performance of geotubes?

- Geotextiles improve the performance of geotubes by providing additional reinforcement and stability. They act as a filtration layer, preventing soil erosion and allowing water to pass through while retaining fine particles. Geotextiles also enhance the strength and durability of geotubes by distributing loads evenly and reducing the risk of punctures or tears.

- Q: Geotextile Model PP200-4-750 What does it mean?

- Is the geotextile 200g / ㎡? Geotextile is generally based on the weight per unit area to divide the specifications. Geotextile manufacturers Zhang Ming Chao for you to answer, I hope to help you.

- Q: How do geotextiles help with subgrade stabilization?

- Geotextiles help with subgrade stabilization by providing reinforcement and separation between different soil layers. They improve the strength and stability of the subgrade by distributing loads more evenly, preventing the mixing of different soil types, and reducing the potential for settlement and deformation.

- Q: Under what circumstances drainage pipes need additional geotextiles

- Infiltration of water under the circumstances, geotextile play a filtering effect, Huazhi geotextile material manufacturers

- Q: How do geotextiles help in preventing shoreline erosion?

- Geotextiles help in preventing shoreline erosion by acting as a barrier against soil erosion caused by water movement. They are placed along the shoreline to stabilize the soil, reduce wave energy, and prevent sediment from being washed away. The geotextiles trap sediment and allow water to pass through, which helps to build up and maintain the beach or shoreline, ultimately protecting it from erosion.

- Q: What are the key factors affecting the puncture resistance of geotextiles?

- The key factors affecting the puncture resistance of geotextiles include the thickness and density of the fabric, the type and strength of the fibers used, the presence of any surface coating or treatment, and the overall construction and quality of the geotextile. Additionally, the puncture resistance can also be influenced by environmental factors such as temperature, moisture, and exposure to chemicals or UV radiation.

- Q: The secondary lining of the tunnel to install the vertical ring to the blind tube hang the geotextile waterproof board generally used for how long

- See the progress of the project

- Q: What are the environmental impacts of using geotextiles?

- The use of geotextiles can have several positive environmental impacts. They help prevent soil erosion by stabilizing slopes and retaining sediment, which reduces the amount of pollutants entering water bodies. Geotextiles also promote vegetation growth by acting as a barrier against weeds and protecting newly planted seeds. Furthermore, they can be used in landfills to prevent leachate contamination and promote proper waste management. Overall, geotextiles contribute to sustainable land use and reduce the negative environmental effects associated with erosion and pollution.

Send your message to us

Mirafi Biaxial Polypropylene Geogrid with High Tensile Strength, Low Elongation, and Good Toughness

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords