Polyurethane waterproof liquid coating good

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 600000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction

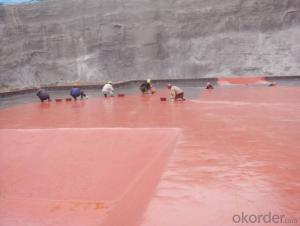

High-strength & High-elasticity Polyurethane Single-component Waterproof Coating (Environment-friendly) is flexible waterproof coating with isocyanate and polyether polyol as principal raw material plus some additives and fillers by polyaddition reaction.

By coating it on the base and through the polyurethane prepolymerization reaction between NCO Terminal group and the moisture in the air, it form into a layer of rubber waterproof film on the base surface, which are toughened, flexible, seamless.

2. Specification

1) Type: Single component Polyurethane Waterproof Coating

2) Material: Isocyanate and Polyether

3) Thickness:1.0mm-3.0mm

4) Density: 1.8-2.0Kg/sqm while thickness is 1.5mm.

5) Packing: 25kg/barrel

6) Loading: 13.5tons/540barrels/20'container

7) Colors: Standard: Red or customized

8) Application Method: Brush

3. Applications

· It’s applicable to waterproof and moisture works of roofing, external walls, basements, balconies, kitchens and lavatories.

· It is suitable for special buildings like granaries, civil air defense works, and bridge projects.

- Q: Bathroom first leveling or do waterproof, what is the difference

- 5. backfill rough flat mortar leveling, and its slope and do waterproof with the grassroots level and grass-roots waterproof, not tired. But pay special attention to this layer of closed water test (for most of the lack of toilet in the ground) is more important. 6. The surface layer and the adhesive layer, requires the slope has been done to slope or squatting, wall tiles to cover the tiles, reduce water into the wall.

- Q: What decoration materials, light and water, and the wall, the perfect combination of glass

- Second, cover the surrounding surface With the tape or the US profile of paper to cover the surface of the interface surface, according to the width of the gap to keep the gap width, width uniformity to ensure that the sealing of the work lines neat and perfect;

- Q: Waterproof mortar expensive or dry mortar expensive

- Dry mortar is usually called hydraulic cement mixed mortar, refers to the dry sieve treatment of aggregate (such as quartz sand), inorganic cementing materials (such as cement) and additives (such as polymers) and so on a certain proportion of physical mixing Into a granular or powdered, in the form of bags or bulk transported to the site, add water, mix directly after the use of materials.

- Q: Cabinet is to buy finished products, or directly to the decoration company to do?

- Finished products to buy relatively easy to do some of the cabinet to do more solid material more assured because the plate is also a long-term environmental protection or woodworking directly do better feel that the company can quote their own under the woodworker comparison

- Q: Self-built concrete house finished three years after the use of large-scale housing wall leakage how to do?

- Third, from the indoor water leakage area for waterproof maintenance.

- Q: Roof leakage, what materials do the best waterproof

- hird, for some of the city building cover the construction of red tiles leakage, as long as the removal of tiles on the grass, moss or dust after the replacement of tiles, leak-proof effect is the same. For flat roofs, the roof of the obvious cracks, with the tool will be cracked into a "V" or "U" shape, filling the caulking ointment, filled with cracks and above the use of waterproof wrap around the package. To strengthen the leak-proof effect, you can also shop a layer of waterproofing membrane. Note: Before the waterproofing and draining construction, the roof must be dry, because the roof of the water does not evaporate, the new waterproof layer will rise, the waterproof effect immediately invalid.

- Q: What are the key points and contents of the quality control of waterproof material?

- 1, polymer cement waterproof coating: it consists of a variety of water-based polymer emulsion and a variety of additives mixed with high-quality cement powder composition. Because of its high cost of polymer emulsion components (about 19,000 yuan / T), and the low cost of powder (about 800 yuan / T), it is because the liquid material, powder huge spread, the vast majority of fraud is to use 801 Glue + fossil powder + green dyestuff + cement blending; the other is to change the liquid material, the proportion of powder will be your liquid material consumption, as much as possible to increase the amount of powder. Resulting in poor waterproof coating adhesion, intolerance, after the completion of the finished product should not be too hard to pull down by hand, and was not much ductility of the sheet or even hand rub a few times into a powder, with blisters Will break down into small pieces. Can also be used to cut the finished product coating and then placed in the refrigerator freezer room after 8 hours to remove, gently forced to break will be broken, and the national standard requirements of the material to achieve low temperature flexibility -10 ℃.

- Q: What is the car material so that the car can be waterproof, in the rain will not leak in?

- ?B. printing, inkjet, photo, screen printing and other technology: refers to the computer will be vector or pixel images into the machine, the machine in accordance with the graphics inkjet or screen technology will color ink printing or screen in a transparent or white base film, And then through the cutting edge along the edge of the pattern; at present most of the manufacturing enterprises (such as motorcycles, electric bicycles, etc.) mass production car stickers are used screen printing process;

- Q: How can the toilet waterproof works fail?

- After the failure of the bathroom waterproofing project to solve the specific needs of the specific analysis of targeted treatment. ??????? Bathroom waterproof is the problem more decoration works. The main reasons are: 1, construction (local, details, etc.); 2, waterproof material problems; 3, the structure (such as uneven settlement, cracking, etc.); 4, to save a little waterproof waterproof measures. ???????? After the three must be redo waterproof, the first type of reasons can be used to the appropriate remedial measures, pay the table "bathroom waterproof failure part of the phenomenon and the remedy list." ??????? Please responsible professionals in the field to carefully check the judge to find specific reasons for dealing with the need to destroy the red or must be destroyed, do not affect others after causing greater losses. The following are the same as the "

- Q: Finished house bathroom waterproof household acceptance should be how to accept?

- 4: coating waterproof layer coating evenly, the thickness of the product to meet the technical requirements, the general thickness of not less than 1.5mm not exposed at the end.

Send your message to us

Polyurethane waterproof liquid coating good

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 600000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords