Polyurethane Insulation Foam Material for Discontinuous Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

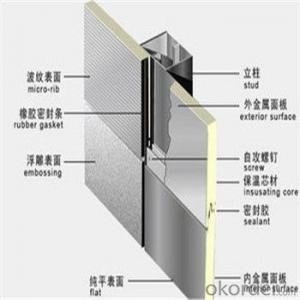

Rigid Blend Polyols for Discontinuous sandwich panels

Rigid Blend Polyol for Discontinuous sandwich panel DBC-402B

Product Introduction

DBC402B blend polyols is a compound which consists of polyether polyols, surfactants, catalysts, foaming agent and flame retardant in a special ratio. The foam has good thermal insulation property, light in weight, high compression strength and flame retardance and other advantages. It is widely used to produce sandwich plates, corrugated plates etc, which applies to make cold stores, cabinets, portable shelters and so on.

Physical Property

Appearance Hydroxyl value mgKOH/g Dynamic viscosity (25°C) mPa.S Density (20°C) g/ml Storage temperature °C Storage stability month | Light yellow transparent viscous liquid 320-400 250-350 1.10-1.16 10-25 6 |

Recommended Ratio

Raw materials | pbw |

DBC-402B blend polyols Isocyanate | 100 100-105 |

Technology and Reactivity(the exact value varies depending on processing conditions)

items | Manual mixing | High temperature machine |

Raw material temperature °C Moulding temperature °C Cream time s Gel time s Free density kg/m3 | 20-25 35-45 30-50 120-200 23-26 | 20-25 35-45 20-30 70-150 23-26 |

Foam Performance

Moulding density Closed-cell rate Thermal conductivity(15°C) Compression strength(perpendicular to the direction of rising) Dimensional stability 24h -20°C 24h 100°C Flame retardant grade | GB 6343 GB 10799 GB 3399 GB/T 8813

GB/T 8811

GB/T8624 | ≥38kg/m3 ≥90% ≤22mW/(m.K) ≥140kPa

≤1% ≤1.5% Level B2 |

FAQ:

1,Could we change the panel size?

Yes, we can product according to your requirement.

2, What is Minumum Production per day?

4000m2 per day x 8 hours.

- Q: Reinforced concrete and metal sandwich board how much difference

- JGJ130 has regulations. Not more than 0.4L, and not more than 500mm

- Q: Similar to the color steel tile, floor board, the roof of the push is how much ah

- 5 cm, 10 cm, 15 cm and 25 cm The general material 5 cm price between 45 to 75 yuan; 75 cm price of 55 to 90 yuan range; 10 cm price of 70 to 100 yuan, Caigang Caigang purification plate thickness can also Custom So we must first understand their choice of materials and thickness, different scenes of the plate is not the same choice

- Q: Sandwich panels and Malacca ecological board what is the difference

- Not count But it is best to mark the gun in the obvious place.

- Q: Color steel sandwich panels and color steel plate What is the difference

- Color steel sandwich panels are divided into rock wool sandwich panels, foam sandwich panels, rock wool color steel sandwich panels

- Q: Can sandwich panels be used for noise barriers?

- Yes, sandwich panels can be used for noise barriers. Sandwich panels are often made of two outer layers of rigid materials with a core of insulating material, which helps in reducing noise transmission. These panels can effectively absorb and block noise, making them suitable for constructing noise barriers in various settings such as highways, construction sites, or industrial areas.

- Q: Color steel sandwich panel price table color steel sandwich board how much money a square meter

- Height of 24m below the double scaffold can be flexible connection, but must be used to withstand the tension and pressure structure.

- Q: Color steel sandwich panels and synthetic resin tile which is more market

- Must be embedded in the concrete beam on the concrete beam, and then fasten the steel pipe connection, the use of steel connection, the connection point can be 2 steps 3 cross, the specific calculation by the book construction

- Q: Can sandwich panels be used for ticket booths?

- Ticket booths can indeed utilize sandwich panels. Composed of two slim outer layers and a thermal insulating core material, sandwich panels possess a reputation for their robustness, longevity, and energy efficiency. These characteristics render them an excellent selection for diverse construction purposes, including ticket booths. By offering insulation against extreme temperatures, reducing noise, and providing fire resistance, sandwich panels offer essential attributes for ticket booths. Furthermore, their lightweight nature allows for effortless transportation and installation. They can be tailor-made to accommodate specific design specifications and require minimal maintenance. Consequently, sandwich panels emerge as a fitting and pragmatic choice for ticket booths.

- Q: Color steel tile and Caigang sandwich board What is the difference between the use of what is the difference

- Color steel room is a color steel composite panels (also known as Caigang sandwich panels) for the wall to light steel structure for the skeleton built. The color galvanized steel coating to maintain a period of 10-15 years, so the theoretical life can be more than 10-15 years, but also with the environment, the use of materials, quality and maintenance methods.

- Q: The stove is dedicated to the plastic used for plastic paper

- Fire level and density does not matter, with the lighter point can not fully explain the problem, b1 level to compound gb8624b1 level

Send your message to us

Polyurethane Insulation Foam Material for Discontinuous Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords