Standing Seam Sandwich Panels Laminboard for Yangtzecool Cold Room

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Container or Wooden Crate and PE Film (Thicken) Refrigeration Unit & Air Cooler: Plywood Case |

| Delivery Detail: | 7-10 Days |

Specifications

Cold Storage

1. Keeping the meat frozen and fresh

2. Easy control

3. Best quality reasonable price

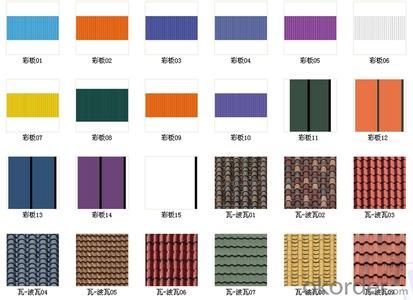

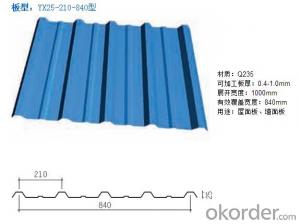

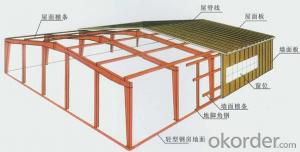

Polyurethane panel: Polyurethane (PU) panel ( insulated panel),the sandwich board rigid polyurethane (PU) foam high pressure, both inside and outside the metal surface layer, the option of color-coated steel plate, PPGI ,embossed aluminum, stainless steel plate and galvanized steel and other materials,PU cold storage is generally modular cold storage, from polyurethane base plate using advanced eccentric rotary combination lock to ensure that the cold intensity.

Size of the Plan of the Polyurethane (PU) panel :Specifications, to meet the different requirements of customers. Characterized as follows: thermal insulation performance, light weight, high strength, corrosion-resistant, anti-aging, beautiful appearance.

Polyurethane (PU) panel thickness: 75mm ,80mm ,100mm ,120mm ,150mm ,200mm

max length 10000mm , width 300mm~900mm ; corner panel max length 3500mm ,width 450mm

Insulation effect : The board and wall of storage all made by uniform mould. Assembly and Disassembly convenient when transportation, installation time limit is short for a project, small and medium-sized refrigerator can delivery in 2-5 days, The storage body can be random combination, separation, or increased, reduced based on user's require.

Test Installation of the cold room : In order to guarantee the job location ,we can first tset to install the cold room in our factory .

Polyurethane panel: Polyurethane (PU) panel ( insulated panel),the sandwich board rigid polyurethane (PU) foam high pressure, both inside and outside the metal surface layer, the option of color-coated steel plate, PPGI ,embossed aluminum, stainless steel plate and galvanized steel and other materials,PU cold storage is generally modular cold storage, from polyurethane base plate using advanced eccentric rotary combination lock to ensure that the cold intensity.

Size of the Plan of the Polyurethane (PU) panel :Specifications, to meet the different requirements of customers. Characterized as follows: thermal insulation performance, light weight, high strength, corrosion-resistant, anti-aging, beautiful appearance.

Polyurethane (PU) panel thickness: 75mm ,80mm ,100mm ,120mm ,150mm ,200mm

max length 10000mm , width 300mm~900mm ; corner panel max length 3500mm ,width 450mm

Insulation effect : The board and wall of storage all made by uniform mould. Assembly and Disassembly convenient when transportation, installation time limit is short for a project, small and medium-sized refrigerator can delivery in 2-5 days, The storage body can be random combination, separation, or increased, reduced based on user's require.

Test Installation of the cold room : In order to guarantee the job location ,we can first tset to install the cold room in our factory .

| Specification of Cold Storage PU panels | |||||

| Specification | 100mm | 125mm | 150mm | 200mm | |

| Average Density(kgs/m3) | 40-42kg/m3 | 40-42kg/m3 | 40-42kg/m3 | 40-42kg/m3 | |

| Operation Temp(°C) | 10°C to -20°C | 10°C to -25°C | 10°C to -40°C | 10°C to -60°C | |

| Resistence to compression(Kg/cm2) | 1.7 | 1.7 | 1.7 | 1.7 | |

| Surface Material | PPGI | 0.376-0.5mm | 0.39-0.6mm | 0.36-0.5mm | 0.4-0.6mm |

| Aluminum | 1.2-1.5mm | 1.2-1.5mm | 1.2-1.5mm | 1.2-1.5mm | |

| S/S | 0.46-0.8mm | 0.46-0.8mm | 0.46-0.8mm | 0.46-0.8mm | |

| PU Panel | Corner Panel | Width by 450+450mm, Length by require | |||

| Wall Panel | Width by 50mm/800mm/475mm/550mm/450mm/375mm, Length by require | ||||

| Connect Type | Cam-lock connection | ||||

| MODULAR COLD ROOM LIST (-5°C to -18°C ) | |||||||

| Model No | Outer Size (mm) | Inner Volume(M3 ) | Floor Space (M2) | Total Power | Door size/Type | Cooling Unit | Refrigerant |

| YTCF-5T | 3000x3000x2500mm | 18 | 9 | 2.8 | 800x1800mm | 3HP | R22/R404a |

| YTCF-6T | 3100x3500x2300mm | 20 | 11 | 3 | 800x1800mm | 3HP | R22/R404a |

| YTCF-10T | 4000X4000X2500mm | 30 | 16 | 3.5 | 800x1800mm | 3HP | R22/R404a |

| YTCF-15T | 5100X5100X2400mm | 50 | 26 | 4 | 800x1800mm | 5HP | R22/R404a |

| YTCF-20T | 6000x6200x24400mm | 75 | 38 | 4.6 | 800x1800mm | 5HP | R22/R404a |

| YTCF-25T | 7000X8000X2400mm | 115 | 56 | 5.5 | 800x1800mm | 5HP | R22/R404a |

| YTCF-30T | 8000x8000x2500mm | 130 | 64 | 6.5 | 800x1800mm | 7.5HP | R22/R404a |

| YTCF-40T | 8200x9000x2400mm | 150 | 74 | 6.8 | 800x1800mm | 7.5HP | R22/R404a |

| YTCF-50T | 9100x10000x3000mm | 240 | 91 | 9 | 800x1800mm | 8HP | R22/R404a |

| YTCF-80T | 12000x12000x3000mm | 380 | 144 | 22 | 800x1800mm | 10HP | R22/R404a |

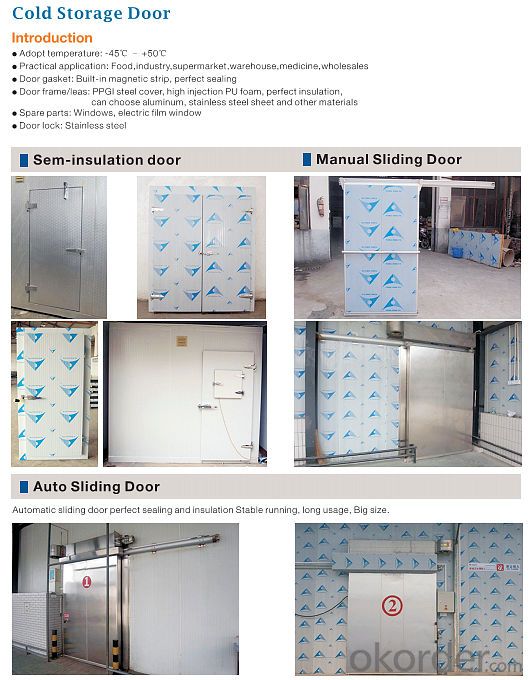

PU(Polyurethane)cold room panel can be choose different surface material as PPGI, Stainless steel, Aluminum sheet Compressor, evaporator, solenoid valves, filters, expansion valves, electrical boxes, cold light, sealants, brass, fittings, elbows, temperature controller( defrost system),Silicon Modular Freezer cold room are available for store fish, meat, chicken, beef in Resturant, seafood market, Cold drinks, meat, poultry, aquatic products, supermarkets, agricultural systems, the pharmaceutical industry, chemical industry, Logistics etc Temperature request must be about <-5°C to-18°C are suittable; Door Size: As above door as standar dimension of cold storage, any size can be customized in by different cold storage design with any open way.Room Size: any size by customazation. | |||||||

- Q: Will the Yanmian sandwich panels do external wall insulation wall can paste tiles? Do A-class insulation of the external wall insulation materials can be posted what kind of it?

- What are the best companies (including imported products) in China?

- Q: Reinforced concrete and metal sandwich board how much difference

- JGJ130 has regulations. Not more than 0.4L, and not more than 500mm

- Q: Are sandwich panels suitable for automotive showrooms?

- Yes, sandwich panels are suitable for automotive showrooms. Sandwich panels are made up of two outer layers or skins with a lightweight core material in between, providing excellent strength and insulation properties. These panels are versatile and can be used for various applications, including building facades, partitions, and interior walls. In automotive showrooms, sandwich panels can be used for constructing walls, ceilings, and even floors. They offer several benefits that make them ideal for this environment. Firstly, sandwich panels provide excellent insulation, which helps maintain a comfortable temperature inside the showroom, regardless of the weather outside. This is crucial for creating a pleasant environment for both customers and staff. Additionally, sandwich panels are lightweight and easy to install, allowing for quick and efficient construction. This is beneficial for automotive showrooms, as they often have tight deadlines and need to be operational as soon as possible. The panels can be easily cut and shaped to fit specific design requirements, allowing for flexibility in creating unique and attractive showroom layouts. Sandwich panels also offer good noise reduction properties, ensuring a quieter environment within the showroom. This is important for providing a comfortable atmosphere for customers and allowing them to focus on the vehicles on display. Furthermore, sandwich panels are durable and require minimal maintenance. They are resistant to corrosion, moisture, and fire, ensuring a long-lasting and safe solution for automotive showrooms. Additionally, the outer layers of the panels can be customized with various finishes and colors, allowing for branding and aesthetic preferences to be incorporated into the showroom design. Overall, sandwich panels are a suitable choice for automotive showrooms due to their insulation properties, ease of installation, noise reduction capabilities, durability, and customization options. They provide a cost-effective and efficient solution for creating a functional and visually appealing environment to showcase vehicles.

- Q: General color steel foam sandwich panels. How much a square is flat

- but generally do not choose the best

- Q: Sun room roof was originally glass, so hot, want to add a layer of foam in the above sandwich panels, what sticky more solid anti-aging!

- Polyurethane sandwich panel insulation good insulation, good overall stiffness, high bearing capacity, suitable for clean room, warehouse, commercial buildings, indoor and outdoor gymnasium, cold storage, indoor partitions and so on. Rock wool sandwich panels fire superior performance, sound-absorbing effect is significant, thermal insulation slightly inferior to polyurethane, but the price is cheaper than polyurethane, suitable for steel structure plant, simple activities of the roof or wall, air clean room ceiling and partition The

- Q: What is the weight per unit area of 100 thick rock wool sandwich panels?

- First, the electricity management: ⒈ temporary electricity must be "" construction site temporary electricity safety technical specifications "JGJ46-88" compilation of electricity construction organization design and development of safe electricity technical measures and electrical fire protection measures. ⒉ temporary electricity engineering drawings must be drawn solely by the electrical engineering and technical personnel, after the approval of the technical person as a temporary basis for construction. ⒊ temporary electricity construction organization design content and steps: ⑴ site exploration, to determine the power line into the total distribution box (cabinet), the distribution of electrical box location and line direction. ⑵ load calculation, select the wire cross-section and electrical type, specifications. ⑶ draw electrical plan, elevation and wiring system diagram.

- Q: How the exterior of the house is made of rock wool color steel sandwich panels

- Construction, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, Erecting outside the scaffolding materials expected ribs of the late section of the dwarf light dog chupu count, template support frame, shelf safety operation technology. Zibu type construction fastener, by the two holes in the diameter of the child is significantly different, the female fastener riveting, two fasteners on the lower cover are steel stamping parts, cover, under the cover with ribs , The upper and lower cover of the middle part of the arc inward convex, the arc-shaped convex surface and the upper and lower cover on both sides of the same cylindrical surface, the child, the female fastener nut on the same size. The fastener is used to build construction scaffolding, building fence, planting greenhouses, etc., can be connected to different diameter pipe, can be rotated angle, wide range of applications, and the fastener weight, bending strength and good steel, , Easy to use.

- Q: 800 * 800 tiles can not stick to the sandwich panel on the wall to do

- Some areas have implemented energy-saving 50% standard, and some areas have already begun to implement 65% of the standard. Insulation material thickness is determined by the design institute according to the specific building shape factor, window wall ratio, wall thickness and other factors.

- Q: Can sandwich panels be used for ticket booths?

- Yes, sandwich panels can be used for ticket booths. Sandwich panels are versatile and commonly used in construction due to their lightweight, durable, and insulating properties. They can be easily customized to meet specific requirements, making them suitable for ticket booths that need to be portable, weather-resistant, and secure. Additionally, sandwich panels offer good thermal and acoustic insulation, ensuring a comfortable environment for booth attendants and customers.

- Q: Sandwich board is the two sides are metal, the middle of the building materials is the problem of foam added: What is the use of more adhesive

- Buy the quality of a little bit of what the material is no problem, although the price is more expensive, but the first safety is important

Send your message to us

Standing Seam Sandwich Panels Laminboard for Yangtzecool Cold Room

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords