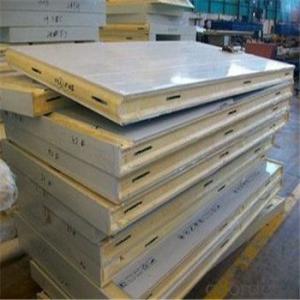

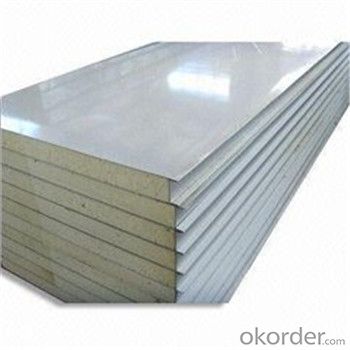

Translucent Polyurethane Foam Cold Room Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

PU panel

1, Good heat insulation function

2, Easy install

3, Corrosion resistance,Long service life

4, ISO 9001:2008 audit

Specifications

1, Thinckness:50/75/100/150/200mm

2, Good heat insulation function

3, Corrosion resistance,Long service life

4, ISO 9001:2008 audit

5, Easy install

Main Applications:

Hotels, hospitals, blood banks, poultry slaughter and processing, aquaculture and processing, mushroom cultivation, agricultural product processing,

dairy production, pharmaceutical processing and logistics, beverage production and processing, beer production and cooling, large-scale logistics

storage, chemical product cooling, leather manufacturing, injection molding, machine cooling, steel cooling, communication equipment,

ship manufacturing and more.

Basic Structure

Panels are joined together by means of tongue and groove and locked together by camlock on each side of the panel to ensure air tight joints.

* Cam-lock design fastener to install cold room tightly and strongly

* Silica gel are used on the panel edge of the joint parts of each sandwich panel to ensure perfect sealing to avoid the cooling air leakage from the cool room or moisture inside the PU insulated panel for the best refrigeration and frozen storage result

Material

Core material of panel | Polyurethane |

Core density | 40~42kg/m3 |

Panel availiable thickness | 50mm,75mm,100mm,120mm,150mm,180mm,200mm |

Material of panels surface | Color plate, Stainless Steel, aluminum,etc. |

Surface of panels thickness | 0.3mm~0.8mm |

Width of the panel | 930mm, 1130mm |

FAQ:

Could be changed the size of the panel?

Yes, according to the requirement of clients.

What is the minimum production?

4000 m2 x 1day x 8 hours.

- Q: I have a temporary pavement, the roof for the Caigang sandwich panels, north and west for the pure glass wall, south of four large area of plastic windows, east brick wall, an area of 150 square feet, 5 meters high. Summer sun good time when the house hot, temperature 35 degrees or more. Ask how the decoration, so that the temperature can come down, the cheaper the better the cost. (The ceiling has no effect, the role of large or small, there is no other way) Thank you, high score waiting. More

- If it is added foam cement insulation board, just add a bubble device, the principle of insulation is the air bubble to reduce heat conduction. Foam plastic cement insulation pedal brother Xi Jiadian tripod end plate is added EPS polystyrene foam, insulation principle is polystyrene foam to reduce heat conduction.

- Q: Air conditioning year after the addition of Calvary is not the reason for refrigeration

- Color steel export tax rebate rate is 13%. Color plate width over 600mm VAT 17%. The export company 's tax rebate formula is: factory tax * 13% / 1.17. The export tax rebate rate is the ratio between the actual tax return of the exported goods and the taxable basis. It is the central part of the export tax rebate, reflecting the country in a certain period of economic policy, reflecting the actual level of export goods tax, the tax rebate rate is based on the actual export of goods to determine the overall tax burden, but also the principle of zero tax and macroeconomic regulation and control principles The product of the combination.

- Q: Reinforced concrete and metal sandwich board how much difference

- Tower crane driver, scaffolding type of work, all kinds of welding workers

- Q: Are sandwich panels suitable for automotive showrooms?

- Sandwich panels are an ideal option for automotive showrooms. Comprised of two outer layers or skins with a lightweight core material in between, these panels offer exceptional strength and insulation qualities. They are versatile and can be utilized in various ways, including building facades, partitions, and interior walls. Within automotive showrooms, sandwich panels can be employed to construct walls, ceilings, and even floors. They bring numerous advantages that make them perfect for this setting. Firstly, they provide excellent insulation, ensuring a comfortable temperature inside the showroom regardless of external weather conditions. This is crucial for creating a pleasant atmosphere for both customers and staff. Moreover, sandwich panels are lightweight and easy to install, allowing for efficient and fast construction. This is advantageous for automotive showrooms, as they often face tight deadlines and need to become operational as soon as possible. The panels can be easily cut and shaped to fit specific design requirements, offering flexibility in creating unique and appealing showroom layouts. Additionally, sandwich panels possess excellent noise reduction qualities, guaranteeing a quieter environment within the showroom. This is significant in providing a comfortable ambiance for customers and enabling them to focus on the showcased vehicles. Furthermore, sandwich panels are durable and require minimal maintenance. They are resilient against corrosion, moisture, and fire, providing a long-lasting and safe solution for automotive showrooms. Additionally, the outer layers of the panels can be customized with various finishes and colors, allowing for the incorporation of branding and aesthetic preferences into the showroom design. In conclusion, sandwich panels are a suitable choice for automotive showrooms due to their insulation properties, ease of installation, noise reduction capabilities, durability, and customization options. They offer a cost-effective and efficient solution for creating a functional and visually appealing environment to showcase vehicles.

- Q: Color steel sandwich panels and color steel plate What is the difference

- Excuse me, where are you in? Indoor insulation is generally made of "polystyrene foam board", the general thickness is 2..3 cm thick, you can understand clearly, in the end is how thick the foam board (when playing screw holes, can be found is thick thick foam board) The There is that you can use .7 inside the expansion screw, to the hardware store to find can match. You can also use welding, then a long screw, is also very simple.

- Q: Sun room roof was originally glass, so hot, want to add a layer of foam in the above sandwich panels, what sticky more solid anti-aging!

- Polyurethane sandwich panel insulation good insulation, good overall stiffness, high bearing capacity, suitable for clean room, warehouse, commercial buildings, indoor and outdoor gymnasium, cold storage, indoor partitions and so on. Rock wool sandwich panels fire superior performance, sound-absorbing effect is significant, thermal insulation slightly inferior to polyurethane, but the price is cheaper than polyurethane, suitable for steel structure plant, simple activities of the roof or wall, air clean room ceiling and partition The

- Q: Will the use of color steel sandwich panels ceiling package package how much money a square? M14 round steel to do hanging bars, 950 sandwich panels, the main bone 160 * 60 * 20 * 2.5 C steel Is the workshop ceiling, I should quote how much appropriate,

- What are the sub-items of the general project that should be prepared for the special safety program? What should be included in the special programming? The following dangerous parts of the sub-sub-projects and temporary electricity equipment in 5 and above or the total capacity of equipment in the 50kW and above the construction site of temporary electricity construction

- Q: The general company to re-change the new version, the replacement is very troublesome. Our company's exterior wall decoration board convenient installation, thermal insulation, waterproof moisture, noise reduction noise are interested can consult. Polyurethane sandwich panels for the application of polyurethane sandwich panels

- First of all, the tempered glass can no longer be drilled high and the ancient antecedant for the short hole, will certainly be broken, and do not make the edge of the local force, but also fragile (so use a few bumps to block it The method is not good) should be tempered glass as a whole embedded in a slot, you can in the low side of the welding of a corner, the length of the glass and the same edge, play a block of the role, in addition, usually the tempered glass is not easy to be deformed Damage, but can not make it too much force

- Q: Are sandwich panels suitable for retail outlets?

- Yes, sandwich panels are suitable for retail outlets. They offer excellent insulation, durability, and aesthetic appeal, making them an ideal choice for creating a comfortable and visually appealing environment for customers. Additionally, sandwich panels can be easily customized to meet specific design requirements and can be installed quickly, minimizing downtime during construction or renovation projects.

- Q: Steel structure workshop roof load is the number of specific Please thank you

- Widely used in large public buildings, public buildings, activities board room, and integrated housing walls and roofs The substrate of the color steel plate is a cold-rolled substrate, a hot-dip galvanizing substrate, and an electro-galvanized substrate Coating types can be divided into polyester, silicon modified polyester, polyvinylidene fluoride and plastic sol The surface condition of the color steel plate can be divided into coated board, embossed plate and printing plate The color steel plate is widely used in the construction of household appliances and transportation industry The construction industry is mainly used for steel industry, airport, warehouse and freezing industry Commercial buildings of the roof walls and doors, etc, civil buildings using less color plate

Send your message to us

Translucent Polyurethane Foam Cold Room Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords