Geotextile Scg Polypropylene Nonwoven Geotextile for Construction Continuous Filament

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

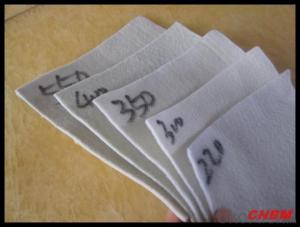

Specification

1. Geotextile Description

Polyester Continuous Filament Spunbonded non woven geotextile

Geotextiles are permeable nonwoven fabrics used to separate,filter,reinforce, protect or drain.Geotextiles allow filtration or separation of granular layers in roads and rail applications,used to protect membranes in landfill applications,used in coastal defence applications and used in landscaping to protect surfaces and structures from weeds and root growth.

2. Packaging & Shipping

Packing: Woven bag

Shipping: About 15 days after receipt the deposit.

3. Specification

Weight: 80gsm-120gsm

Width: 1m-6m

Length: as required;

Color: White, Black, As required

4. FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: Can geotextiles be used in slope stabilization projects?

- Yes, geotextiles can be used in slope stabilization projects. Geotextiles are often used to reinforce and stabilize slopes by providing strength and stability to the soil. They can help prevent erosion, control surface water runoff, and improve the overall stability of the slope.

- Q: Acupuncture geotextile is divided into several kinds of how is it used?

- Acupuncture geotextile is now divided into two types, according to the fiber form to points. Continuous fiber called filament acupuncture non-woven geotextile. A few centimeters of length fibers made of staple fibers for nonwoven geotextiles. Use is not used, mainly used in geotechnical engineering in the filter, isolation, drainage and so on.

- Q: Whether the geotextile filter layer includes a plastic mesh

- Hello, geotextile can be used as a separate filter and grid sand with as a filter layer, Huazhi geotextile material manufacturers for you to answer

- Q: What is the number of tensile units for geotextiles

- Personal sense of the number of stretching units is mainly for the sparse geotextile geotextile, geotextile, geogrid or other similar loose structural materials, sample 1m width of the number of stretching units is 1m width of the number of holes or how many cells, The number of stretched units within the test is the number of holes or the number of cells in the test width. For example, geotextile geogrid 1m width of 25 holes, the number of stretching unit is 25, the sample width of 200mm with 5 holes, the number of drawing unit is 5, C = Nm / Nsc = 25/5 = 5 individuals Understanding is not necessarily advice

- Q: Concrete pavement or geotextile

- Do not add, with the asphalt Ma plug Seal if you have to choose the best choice for geotextile waterproof the best

- Q: The secondary lining of the tunnel to install the vertical ring to the blind tube hang the geotextile waterproof board generally used for how long

- Need to see the progress of construction workers, geotextiles need it

- Q: Can China produce polypropylene filament geotextiles? Google knows

- Yes, I am professional production, wish smooth

- Q: Geotextile puncture test standard

- Staple stitch filament piercing filament woven weaving

- Q: Can geotextiles be used for erosion control in construction sites?

- Yes, geotextiles can be used for erosion control in construction sites. Geotextiles are designed to provide stability and prevent erosion by reinforcing soil and filtering water. They are commonly used in construction projects to control sediment runoff, stabilize slopes, and protect against soil erosion.

- Q: Waterproof and protective layer between which type of geotextile isolation layer

- Personally think to take impervious geotextile. Anti-seepage geotextile has excellent water permeability, filterability, durability, can be widely used in railways, highways, sports museum, dams, hydraulic construction, then hole, coastal beach, reclamation, environmental protection and other projects. Mainly staple acupuncture non-woven geotextile and split film woven geotextile. Check the original post & gt; & gt; trouble to adopt, thank you!

Send your message to us

Geotextile Scg Polypropylene Nonwoven Geotextile for Construction Continuous Filament

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords