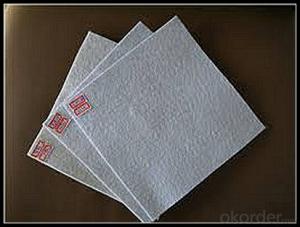

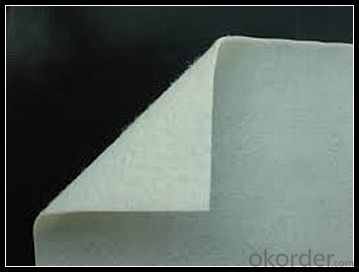

Geotextile Lowes Polypropylene Nonwoven Geotextile Fabrics High Strength Materials for Filtration

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geotextile Functions

Separation

CNBM Geotextile acts as a separator between two layers of soil that have different particle size distributions. CNBM Geotextiles are used to prevent road base materials from penetrating into soft underlying sub grade soils, thus maintaining design thickness and roadway integrity. Separators also help to prevent fine-grained sub grade soils from being pumped into permeable granular road bases.

Filtration

CNBM Geotextile acts similar to a sand filter by allowing water to move through the soil while retaining all upstream soil particles. CNBM Geotextiles are used to prevent soils from migrating into drainage aggregate or pipes while maintaining flow through the system. CNBM Geotextiles are also used below rip rap and other armour materials in coastal and river bank protection systems to prevent soil erosion.

filtration

Reinforcement

CNBM Geotextile acts as a reinforcement element within a soil mass or in combination with the soil to produce a composite that has improved strength and deformation properties over the unreinforced soil. CNBM Geotextiles are used to add tensile strength to a soil mass in order to create vertical or near vertical reinforced soil walls and steep slopes.

Reinforcement

Drainage

CNBM Geotextile acts as a drain to carry fluid flows through less permeable soils or construction structures. CNBM Geotextiles are used to dissipate pore water pressures at the base of roadway embankments. The use of Geotextiles in drainage systems ensures an ongoing drainage of fluids with minimum pressure loss by flowing in-plane of the fabric away from the construction.

Drainage

Protection

Due to excellent static puncture resistance, CNBM Geotextiles protect waterproof membranes and other sealing materials from puncture when fill material and loads are applied. When placed between sealing materials and other layers, CNBM Geotextiles and resists and distributes local pressure from the layer above, ensuring that the protected material is not stressed to failure.

Geo Textiles

CNBM segment comprises of technical textile products used in Geotechnical applications pertaining to soil, rock, earth etc.

This class of product is loosely called Geotextiles.

However Geotextiles particularly refers to permeable fabric or synthetic material, woven or non-woven, which can be used with geotechnical engineering material.

The principal functions performed by Geotextiles are

Confinement /separation,

Reinforcement

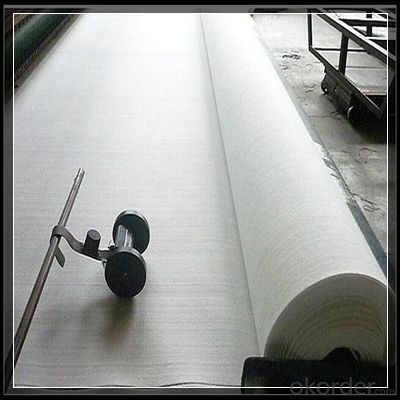

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in geothermal energy projects?

- Yes, geotextiles can be used in geothermal energy projects. Geotextiles are often used as a filtration and separation layer in geothermal systems, helping to prevent fine particles from clogging pipes and equipment. They can also be used as a reinforcement layer to improve the stability and load-bearing capacity of the ground in geothermal installations.

- Q: Does the color cloth be geotextile?

- Straw, sacks, stone, gravel, wood, steel, color cloth, lighting equipment, transport, alarm equipment, digging tools, lead wire, cement, soil, sand, geotextile and so on.

- Q: Weaving geotextile construction should pay attention to what

- Weaving geotextile construction specifications: 1, before the construction of roadbed should be integrated clean up, the surface shall not have sharp corners. 2, geotextile is best to use mechanical erection, can also be used artificial laying. When laying, it should be noted that the rough side of the singeing up, and then one end fixed with a fixed, mechanical or human tension, tensile elongation of about 1 & amp;% to 1 & amp;%, Facing front laying. The fixture includes fixed and fixed metal. Fixed nails should be used cement nails or nails, nail length 8 ~ 10cm fixed iron can be thick lmm, width 3mm of the strip. 3, weaving geotextile and the length of the long, should be used industrial sewing machine sewing, sewing method using "dow" and "seam". Suture and geotextile should have a significant color difference in order to facilitate inspection.

- Q: Are geotextiles recyclable?

- Yes, geotextiles are recyclable. They can be reused or repurposed for various applications, reducing waste and promoting sustainability. However, the recyclability may vary depending on the specific type and composition of the geotextile.

- Q: How do geotextiles help with vegetation establishment?

- Geotextiles help with vegetation establishment by providing a stable and favorable environment for plant growth. They act as a barrier against weed growth, erosion, and sedimentation, while allowing water and nutrients to pass through. Geotextiles also protect newly planted vegetation from wind damage and promote healthier root development, leading to successful establishment and growth of plants.

- Q: How do geotextiles improve the performance of foundations?

- Geotextiles improve the performance of foundations by providing separation, filtration, and reinforcement functions. They prevent the mixing of different soil layers, allowing for better load distribution and reducing the risk of settlement. Geotextiles also act as filters, allowing water to pass through while retaining soil particles, which prevents clogging and maintains the stability of the foundation. Additionally, geotextiles reinforce the soil, increasing its strength and enhancing the overall stability and load-bearing capacity of the foundation.

- Q: Basement roof cover soil thickness and geotextile shop in what position,

- The size of the thickness of the roof cover of the basement garage is in the specification of the air defense design

- Q: What are the different geotextile weight classes and their applications?

- Geotextile weight classes range from lightweight to heavyweight, typically categorized as classes 1 through 5. Class 1 geotextiles are lightweight and used for erosion control, filtration, and separation in landscaping and gardening projects. Class 2 and 3 geotextiles are medium-weight and commonly used for road construction, pavement reinforcement, and drainage applications. Class 4 geotextiles are heavy-duty and suitable for shoreline protection, slope stabilization, and landfill lining. Lastly, Class 5 geotextiles are the heaviest and used in geotechnical engineering for applications such as soil stabilization, embankment reinforcement, and railway construction.

- Q: Where to sell black geotextile prices

- Those who produce geotextile manufacturers are selling black geotextile. Black geotextile according to the use of a lot of specifications, the price difference is very large. The weight per square meter between about 50-1000g grams, the weight of different unit price is different, the inquiry directly asked how much money per ton. According to the use of distinction between the current market price per ton price between 5,000 yuan - yuan. For the conservation, isolation, insulation of the geotextile the cheapest. In the 5000 yuan / ton between. For the filter, soft base treatment, slope protection, reinforced decoration, and other purposes of the black geotextile most expensive in - yuan / ton. The same black color, but different uses, production processes and production costs are not the same.

- Q: JTGF80 / 1-2004 "standard" 4.5 Geosynthetics in the treatment of the measured items in the "anchoring length", in the construction design diagram, the provisions of the value of the allowable deviation should be how to implement? Question added: Sorry! I missed a few words. When the construction design is not indicated, the specified value, the allowable deviation value should be implemented? JTGF80 / 1-2004 "standard only write to meet the design, construction requirements. I did not say that the design of the length of the anchorage is how much, can not find the construction technical specifications. So I do not know the provisions of the value of how to allow deviation? More

- Specifically not less than the specified value, does not exceed the allowable deviation. This is the so-called construction by specification! You refer to JTG assessment standard -2004 is correct! I have the data to let you refer to the next / geogrid and geotextile landscape is greater than or equal to 50cm, vertical is greater than or equal to 150com

Send your message to us

Geotextile Lowes Polypropylene Nonwoven Geotextile Fabrics High Strength Materials for Filtration

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords