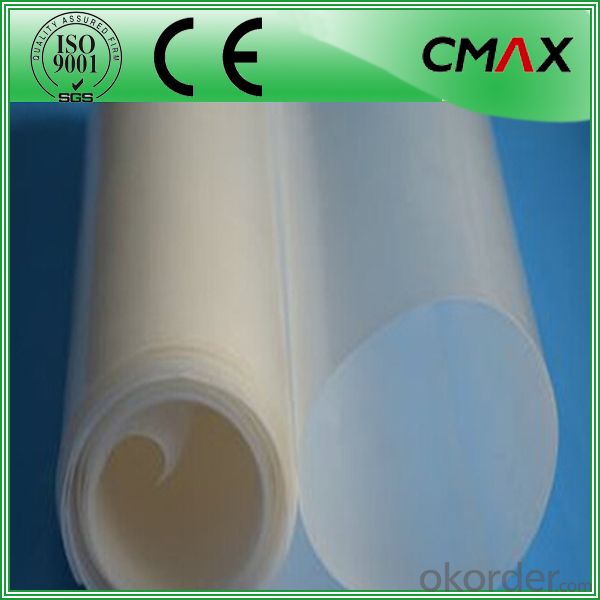

Geotextil N3 Polyethylene Polypropylene Waterproof Membrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

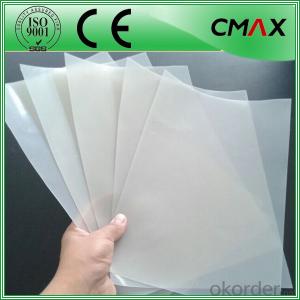

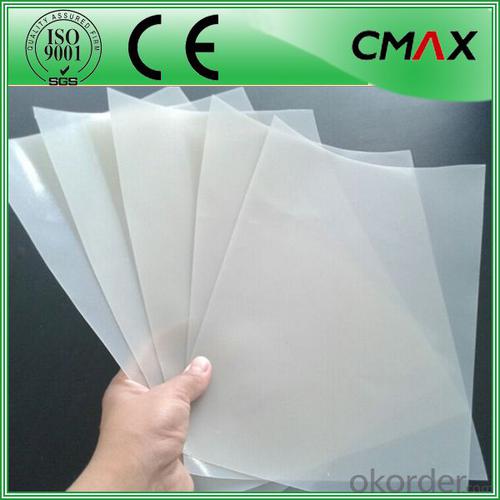

Polyethylene Polypropylene Waterproof Membrane

Geomembrane Features:

Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance, anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life. water, drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications and low cost, simple construction.

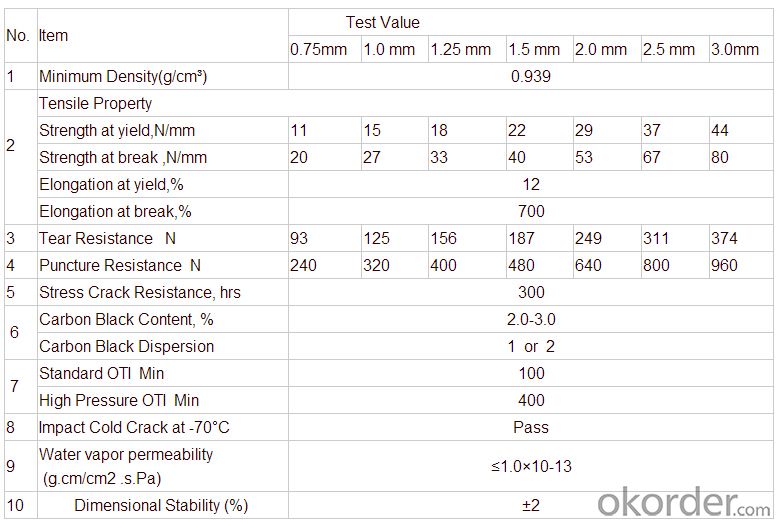

Specifications and Technical datas:

| Thickness | 0.15mm - 4.0mm |

| width | Within 8 m |

| length | 50-100m/roll (at request) |

| Material | HDPE,( LDPE, LLDPE, PVC, EVA ) |

| Color | Black , white , grey |

| Optional surface | Textued(one or two side) or smooth surface |

| Manufacturer | The biggest geomembrane liner manufacturer/factory in China for many years |

Details of our products:

Applications:

1) Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6) Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.) .

Packing and shipping:

1. The outer package: black or white woven geotextile.or we can make the package as your requst.

2. Different tgram/ roll size for different qty in the same containers.

3. Roll size: 3.95m*200 for container

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: Is the case, we detect the company now want to engage in expansion (that is, increase the test items), the need for material to do qualification certification. But I have not done before, do not know their own data done unreasonable. Take the data mainly for reference, know the approximate range of the various parameters. Question added: it is best to have data logging source and derivation formula to support the reasonableness of this result, thank you! More

- Hello, can only help you this, do not know useful to you useless factory production geotextile geomembrane drainage board

- Q: Can geotextiles be used in mining tailings management?

- Yes, geotextiles can be used in mining tailings management. Geotextiles are commonly used in mining operations to provide stability and containment for tailings, which are the waste materials left over after the desired minerals have been extracted. They can be used to line tailings storage facilities, prevent erosion, control water flow, and promote soil filtration, thus enhancing the overall management and mitigation of mining tailings.

- Q: Geotechnical construction of the weather when there is any requirement

- Geotechnical construction of the weather when there is any requirement

- Q: What is the meaning of the process equipment and equipment for producing geotextiles?

- What is the meaning of the process equipment and equipment for producing geotextiles?

- Q: Can geotext prevent rooting?

- Use a composite geotextile on it

- Q: Can geotextiles be used in erosion control in stormwater detention ponds?

- Yes, geotextiles can be used in erosion control in stormwater detention ponds. Geotextiles are commonly used to stabilize and reinforce soil, prevent erosion, and filter water in various construction and environmental applications, including stormwater management. By placing geotextiles on the slopes and bottoms of stormwater detention ponds, they can help prevent soil erosion caused by the flow of stormwater, reduce sedimentation, and improve the overall effectiveness of the pond in controlling and managing stormwater runoff.

- Q: Supply Tianhe District staple geotextile and anti-geotextile what is the same

- Staple geotextile is made of polyester staple fiber by acupuncture, because it can play the role of anti-filtration, and thus staple geotextile can also be called anti-geotextile. Filter geotextile is based on the use of the name, so long as it is able to play the role of anti-filter geotextile called geotextile filter, geotextile, including geotextile geotextile, filament geotextile, the preparation of geotextile, Woven geotextile, non-woven geotextile, polypropylene geotextile. Tianhe District used staple geotextile and anti-filter geotextile is the same.

- Q: Geotextile strength index with interpolation method how to calculate? Then geotextile variation, I do not quite understand, pro, if you know whether to tell me Oh! Very anxious

- Geotextile strong indicators of the interpolation method: For example: geotextile 150 grams of breaking strength is 4.5KN, geotextile 100 grams of breaking strength is 2.5KN, then the geotextile 130 grams of broken strength is how much? The calculation method is: 4.5KN-2.5KN = 2KN (that is, 50 grams of geotextile strength) 2KN by 50 grams multiplied by 30 grams is equal to 1.2KN then geotextile 130 grams of breaking strength is 3.7KN.

- Q: Can geotextiles be used in the construction of agricultural ponds?

- Yes, geotextiles can be used in the construction of agricultural ponds. Geotextiles can be employed as a barrier or liner in the pond to prevent seepage, erosion, and contamination. They help in stabilizing the soil and provide reinforcement, ensuring the longevity and durability of the agricultural pond.

- Q: What are the key properties to consider when evaluating geotextiles?

- When evaluating geotextiles, key properties to consider include strength, permeability, durability, and compatibility with the surrounding environment.

Send your message to us

Geotextil N3 Polyethylene Polypropylene Waterproof Membrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords