Polyester Geogrid/ Fiberglass Geogrid/ PP Biaxial Geogrid for Dam

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

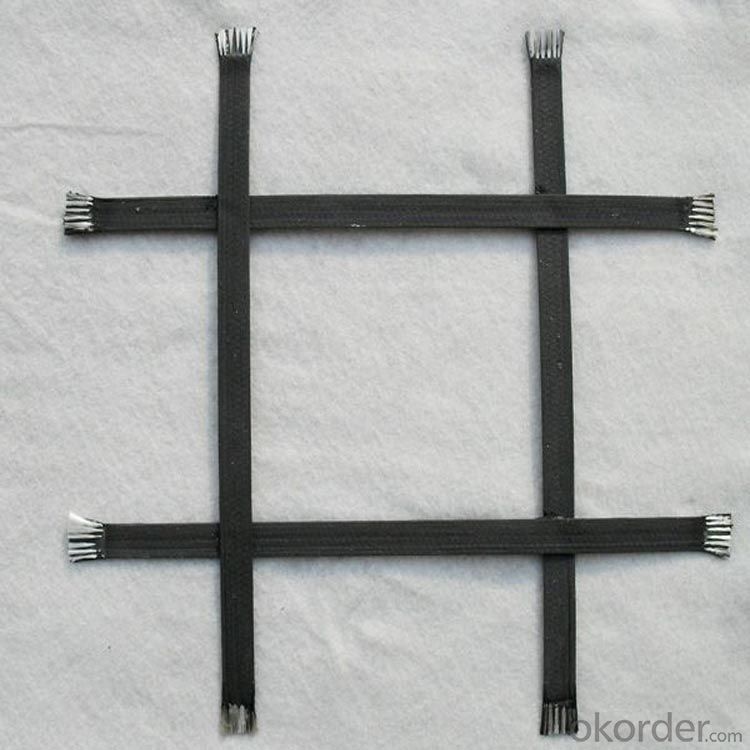

Introduction of Fiberglass Geogrid:

pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair. as well as convenience in construction and low price.

Fiberglass geogrid is based on fiberglass woven cloth coated with modified bitumen or PVC, it was developed to address the problem of

It is characterized by high tensile strength in axial and lateral directions, low stretch rate, alkali-resistance, low temperature- resistance,

Performance of Fiberglass Geogrid:

and finally stretched in longitudinal and transverse directions. Introduction of PP/HDPE Uniaxial Geogrid: and finally stretched in the longitudinal direction.

--- High strength, high modulus and low temperatures resistance.

--- Reinforcement for road pavement

--- Reinforcement for railway basement

--- Reinforcement for Slope

--- Reinforcement for embankment.

Introduction of PP Biaxial Geogrid:

Biaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern,

Features of PP Biaxial Geogrid:

1. With high tensile strength in longitudinal and transversedirections

2.This structure can provide an chain system of more effective force bearing and spreading for the soil.

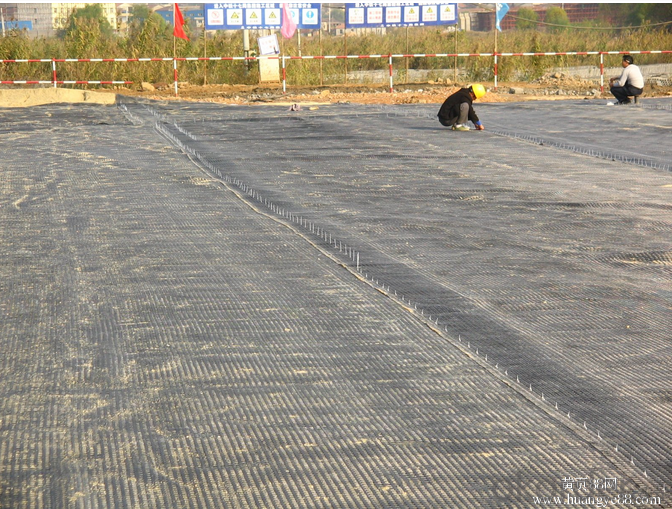

Application of PP Biaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing project cost and maintenance cost.

Uniaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern,

Features of PP/HDPE Uniaxial Geogrid:

With high tensile strength and tensile modulus

Application of PP/HDPE Uniaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects, retaining wall, dam etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing area , project cost and maintenance cost.

Features of Polyester Geogrid:

1) High tensile strength

2) High tear-resistant

3) Strong combination with gravel and soil

Application of Polyester Geogrid:

It mainly applied in strengthening soft ground of rail and road.

Sarah

- Q: How are geosynthetic materials used in retaining wall reinforcement?

- Geosynthetic materials are commonly used in retaining wall reinforcement to enhance the stability and strength of the structure. They are placed in layers between the soil and the wall to provide additional support, prevent soil erosion, and distribute the lateral forces exerted on the wall. These materials, such as geotextiles and geogrids, increase the overall performance and lifespan of the retaining wall by improving its resistance to deformation and failure.

- Q: Can earthwork products be used in shoreline protection?

- Yes, earthwork products can indeed be used in shoreline protection. These products, such as geotextiles, geocells, and gabion baskets, are commonly used to stabilize slopes, control erosion, and provide structural support along shorelines. They can help mitigate wave action, prevent erosion, and create barriers against water intrusion, making them effective tools in shoreline protection efforts.

- Q: What are the maintenance requirements for earthwork products?

- The maintenance requirements for earthwork products typically involve regular inspection, cleaning, and repair as needed. It is important to monitor the condition of the products to ensure they remain structurally sound and free from damages. Additionally, any erosion or settling should be addressed promptly to maintain optimal performance. Regular maintenance can prolong the lifespan of earthwork products and ensure their effectiveness in various applications.

- Q: How do geosynthetic liners prevent leakage in reservoirs and ponds?

- Geosynthetic liners prevent leakage in reservoirs and ponds by creating a barrier between the water and the underlying soil. These liners are made from synthetic materials that are highly impermeable, such as high-density polyethylene (HDPE) or polyvinyl chloride (PVC). They are installed as a lining system, ensuring complete coverage of the reservoir or pond bottom and sides. The liner acts as a barrier, preventing water from seeping through the soil or rock layers underneath, thus effectively containing and preserving the water within the reservoir or pond.

- Q: How do geocomposites aid in soil filtration in earthwork projects?

- Geocomposites aid in soil filtration in earthwork projects by providing a barrier that allows water to pass through while effectively filtering out fine particles and contaminants. This helps to maintain the stability and integrity of the soil, preventing erosion and promoting better drainage.

- Q: How do geotextile tubes help in marine construction?

- Geotextile tubes are beneficial in marine construction as they provide a cost-effective and efficient solution for various applications. These tubular structures are filled with sand or other suitable materials and installed in water bodies to create barriers, breakwaters, or protective structures. They help in shoreline stabilization, erosion control, land reclamation, and sediment containment. Geotextile tubes also provide dewatering capabilities, allowing excess water to drain while retaining the solid particles. Their flexibility, durability, and ease of installation make them a preferred choice in marine construction projects.

- Q: How do geosynthetic products contribute to soil erosion prevention in recreational areas?

- Geosynthetic products, such as geotextiles and geogrids, play a crucial role in preventing soil erosion in recreational areas. These products are designed to provide reinforcement and stabilization to the soil, preventing it from being washed away by water or wind. They are commonly used in the construction of retaining walls, slope stabilization, and erosion control measures like terracing. By effectively containing the soil and reinforcing its structure, geosynthetic products minimize soil erosion and ensure the longevity and safety of recreational areas.

- Q: What are the benefits of using geogrids in bridge abutment reinforcement?

- Geogrids offer several benefits when used in bridge abutment reinforcement. Firstly, they provide excellent soil stabilization, preventing erosion and reducing the risk of slope failures. Secondly, geogrids enhance the load-bearing capacity of the soil by distributing the weight more evenly, thus minimizing settlement and settlement-related damage. Thirdly, they improve the overall durability and longevity of the bridge abutment by reducing the potential for cracking and structural damage. Additionally, geogrids are cost-effective and easy to install, making them a practical choice for bridge abutment reinforcement projects.

- Q: What are the different design options available for earthwork products?

- There are various design options available for earthwork products, including different shapes, sizes, and materials. Some common design options include retaining walls, slope stabilization systems, drainage systems, erosion control products, and geosynthetic materials. These options can be customized to suit specific project requirements, ensuring efficient and effective earthwork solutions.

- Q: What are the key factors to consider when choosing earthwork products?

- When choosing earthwork products, it is essential to consider factors such as the quality and durability of the materials, their compatibility with the project requirements, the reputation and reliability of the manufacturer, as well as any additional features or benefits that can enhance the efficiency and effectiveness of the earthwork.

Send your message to us

Polyester Geogrid/ Fiberglass Geogrid/ PP Biaxial Geogrid for Dam

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords