Geotextile Amazon Best Quality Polypropylene Fiberglass Geogrid for Dikes and Dams

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Geogrid allows assembling within the temperature range from -40°C to +60°C. The material is neutral to aggressive environments and ecologically safe. Laying does not require additional machinery. In fold position geogrid does not take much place.

Porducts Description

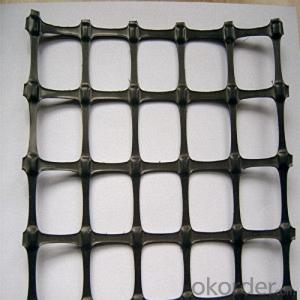

Classify Fiberglass Geogrid Classify Polyester Geogrid

Material Fiberglass Material Polyester

Tensile Strength: 25-25KN; 30-30KN; 50-50KN; 80-80KN; 100-100KN; 120-120KN;

Road Size: 3.95x100m; as customer required;

Application

1. Roadbed reinforcement in highway, railway and municipal road, prevent road surface crack

2. Reinforcement and separation in dam and river, improve soft soil bearing capacity and stability.

Application

1. Roadbed reinforcement in highway, railway and municipal road, prevent road surface crack

2. Reinforcement and separation in dam and river, improve soft soil bearing capacity and stability.

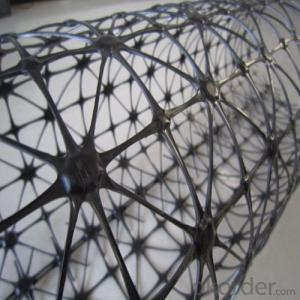

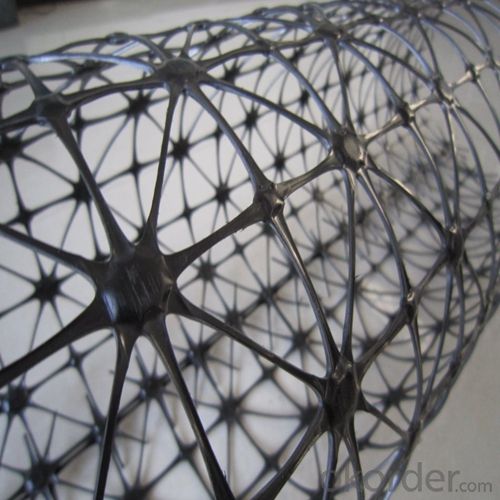

fiberglass geogrid/glass fiber geogrid with CE certificateIntroduction: Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is composed of fiberglass filaments that are coated with an inorganic sizing agent

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in rockfall protection works?

- Yes, geotextiles can be used in rockfall protection works. Geotextiles can provide reinforcement and stabilization to slopes and embankments, helping to prevent soil erosion and rockfall. They can be used as a barrier between the rockfall source and the protected area, absorbing or redirecting the energy of falling rocks. Additionally, geotextiles can enhance the effectiveness of other rockfall protection measures, such as rockfall nets or fences, by providing additional support and filtration.

- Q: Where is the non-woven geotextile in the tunnel?

- The nonwoven geotextile is used to isolate the dome between the concrete and the waterproof layer in the tunnel.

- Q: What are the different geotextile installation techniques for landfill applications?

- There are several geotextile installation techniques commonly used for landfill applications. These include the direct placement method, the trench method, the soil cover method, and the liner method. The direct placement method involves placing the geotextile directly on the subgrade or waste material, while the trench method involves placing the geotextile in a trench and then covering it with soil. The soil cover method involves placing the geotextile on top of the waste material and then covering it with a layer of soil. The liner method involves placing the geotextile on top of a geomembrane liner to provide additional protection and support. Each method has its own advantages and considerations depending on the specific requirements of the landfill site.

- Q: Can geotextiles be used in riverbank stabilization projects?

- Yes, geotextiles can be used in riverbank stabilization projects. Geotextiles are often employed to reinforce and protect soil in various civil engineering applications, including riverbank stabilization. They can help prevent erosion, control sediment movement, and provide stability to riverbanks by improving soil strength and drainage.

- Q: How do geotextiles aid in the filtration of water?

- Geotextiles aid in the filtration of water by acting as a barrier that allows water to pass through while trapping and filtering out sediment, dirt, and other contaminants. They help to prevent clogging and maintain the permeability of soil, improving the overall quality of water that passes through them.

- Q: Performance index of composite geotextile

- Item Unit Area Quality g / m000 Remark Film Thickness mm0.25-0.350.3-0.5 Fracture strength KN / m57.510.012.014.016.018.0 Longitudinal transverse elongation% 30-100CBR Breaking strength KN≥1.11.51.92. 22.52.83.0 Tearing strength KN≥0.150.250.320.40.480.560.62 Vertical and horizontal peel strength N / cm6 Vertical and horizontal permeability coefficient cm / sk * 10-11-10-13k = 1.0-9.9

- Q: How do geotextiles help with soil reinforcement in soft ground conditions?

- Geotextiles help with soil reinforcement in soft ground conditions by providing a stable and strong layer that distributes the load more evenly. They act as a barrier and prevent the intermixing of different soil layers, improving the overall stability and strength of the ground. Additionally, geotextiles can help with drainage by allowing water to pass through while retaining the soil particles, preventing erosion and maintaining the integrity of the ground.

- Q: Geogrid Specifications TGSG40-40 What does it mean?

- The company mainly produces all kinds of plastic geogrid, steel-plastic composite geogrid, glass fiber geogrid, warp-knitted polyester geogrid, geotextile, geotextile, geogrid, geotextile Cloth, composite geomembrane, bentonite waterproof blanket, a new three-dimensional geotextile mats, geocell and other engineering materials. Product quality and cheap, complete specifications can be customized, welcome to all customers to 153 154 154 85 inquiries 77, to plant inspection, I will be happy to serve you!

- Q: What are the different methods of geotextile testing for strength and durability?

- There are several methods used to test the strength and durability of geotextiles. Some common methods include grab tensile strength testing, puncture resistance testing, tear resistance testing, burst strength testing, and UV resistance testing. Each method assesses specific properties of the geotextile to determine its strength and durability in various conditions and applications.

- Q: What are the different geotextile installation techniques in erosion control?

- Some of the different geotextile installation techniques in erosion control include trenching, anchoring, stapling, and sowing. Trenching involves digging a trench and placing the geotextile into it, allowing it to filter water runoff and prevent erosion. Anchoring involves securing the geotextile to the ground using stakes or other fasteners to prevent movement. Stapling involves using staples or pins to secure the geotextile to the ground, providing stability and erosion control. Sowing refers to mixing seeds with the geotextile material and then laying it down, allowing vegetation to grow and reinforce the soil. These techniques can be used individually or in combination to effectively control erosion.

Send your message to us

Geotextile Amazon Best Quality Polypropylene Fiberglass Geogrid for Dikes and Dams

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords