Plastic Grass Grid used for Lot Grass Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1,Description of Plastic Grass Grid used for Lot Grass Protection

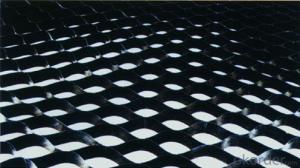

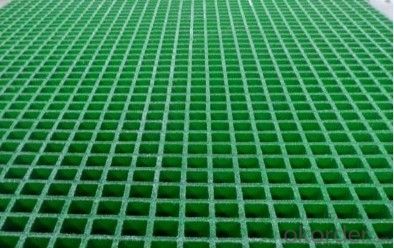

Nature Planting grass grid using modified high molecular HDPE as raw materials , Green and Environmental Protection , Completely recyclable , it can perfect realize to combine the lawn and parking lot,it can bear pressure , abrasion resistance, impact resistance, antiaging, corrosion resistance , improve the quality , and save the investment; unique flat plug type overlap joint , improve work efficiency and quick install , can adjust expansion joint .

Material : Modified high molecular HDPE , Fiberglass , Nanometer oxide , Coloring Material ( standard ratio) .

Color : green color or other any specified color

Bearing capacity : The hightest 200T/m2

2,Specialities of Plastic Grass Grid used for Lot Grass Protection

1) Fully green grass, provides more than 95% planting grass area, completely greening effect , can sound-absorbing, vacuuming, significantly improve the environmental quality and taste.(Reference: concrete planting grass brick only 30% interspace )

2) Saving the investment .

3) Nature Planting grass grid can perfect realize to combine the parking and greening . In land-scarce city , it can save developers valuable investment .

4) Leveling , neat, integrity .

5)Unique and stable flat plug type overlap joint make the whole pavement surface as the flat entirely , avoid part place sinking , so the construction is very convenient .(Reference: concrete planting grass brick is independent each one , it must be pouring concrete foundation layer , so can keep flat and integrity ) .

6) High strength , long life service .

7)Nature Planting grass grid use special material with patent technology , maximum stress tolerance can meet 200T/m2 , greater than 32T/m2 for standard requirement fire fighting high surface .

8) Stable performance , anti-UV , resistance to acid and alkali corrosion , anti-wear and pressure , anti-temperature -40°C-90°C. (Reference : concrete planting grass brick will be easy to craze and damage when temperature variation ) .

9) Good drainage .

10) Gravel bearing layer provides good drainage function , so that easy to drain excessive rainfall .

11) Lap joint . flat plug type overlap joint , very convenient , arbitrarily adjust expansion joint width , to fit temperature change

3, Application of Plastic Grass Grid used for Lot Grass Protection

Parking lot , Fire fighting access , Fire fighting high surface , Golf lane , Conference and exhibition center , Modern workshop , Upscale community , Roof garden and so on .

4,Construction suggestions:

Foundation soil should be compaction as different layers , Compactness should be reach more than 85% .

Gravel bearing should be paved 350 thickness (Fire lane should be 600 thickness) , spread out to flat and grind to compaction .

Gravel or coarse sand should be paved 20thickness .as the flat layer .

Pave and install grass grid can be cut to suitable size by saw , and you should leave a few millimeters slit between grid and grid .

Sowing planting soil on the grid surface from the top about 1.0cm

Lay down in grass or sowing grass seed . While lay down in grass , .turfing has to be compacted , watering and maintaining , you can park car when grass grow .Protecting lawn .

Gravel bearing layer can supply some store water function , this is beneficial for lawn grow , grass roots can grow to gravel layer .(Reference: concrete planting grass brick only has small space , and when under summer sunshine , temperature will reach more than 50 °C ) .

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1>How about your company?

A manufacturer & supplier focuses on the production of construction materials, including but not limited to PP staple fiber, geotextile geo-grid, geo-bag etc. Customized product is also available based on your detailed requirements.

2>How long can we receive the product after purchase?

It takes about 1 to 4 weeks to finish the production based on the specific production schedual. Then it will depend on the shipping time from loading port to the destination port.

- Q: Production of geomembrane equipment which are such as the production of geotextile need to press machine, open charter, carding machine, etc.

- Mixing machine, screw extruder, heating die, circulating fan, traction machine, into a roll machine.

- Q: Can geotextiles be used in mining tailings management?

- Yes, geotextiles can be used in mining tailings management. Geotextiles are commonly employed as part of a containment system to prevent the spread of contaminated tailings and to provide stability to the tailings impoundment. These textile materials can help separate and filter the solids from the liquid in tailings, reducing the risk of water pollution and improving the overall management of mining waste.

- Q: How do geotextiles help in the reinforcement of soil?

- Geotextiles help in the reinforcement of soil by providing stability and strength to the soil structure. They act as a barrier between different soil layers, preventing their mixing and maintaining their integrity. Geotextiles also distribute the load evenly across the soil, reducing the risk of settlement or subsidence. Additionally, they improve drainage and filtration by allowing water to pass through while preventing the loss of fine particles. Overall, geotextiles enhance the overall performance and longevity of soil in various engineering and construction applications.

- Q: What is the effect of temperature on geotextile performance?

- The effect of temperature on geotextile performance can vary depending on the specific type and composition of the geotextile. In general, higher temperatures can cause geotextiles to become more flexible and pliable, which can enhance their ability to conform to irregular surfaces and provide better soil stabilization. However, extremely high temperatures can also lead to thermal degradation and loss of strength in certain geotextiles. Conversely, colder temperatures can make geotextiles stiffer and less flexible, potentially reducing their ability to perform certain functions such as filtration or separation. Therefore, it is crucial to consider the anticipated temperature conditions when selecting and designing geotextiles for specific applications.

- Q: What are the specifications for geotextiles used in transportation projects?

- The specifications for geotextiles used in transportation projects generally include criteria such as tensile strength, puncture resistance, thickness, permeability, and durability. These specifications ensure the geotextiles can effectively separate, reinforce, and filter materials in road construction, preventing the mixing of soil layers, enhancing stability, and improving drainage.

- Q: Can geotextiles be used in the protection of pipelines?

- Yes, geotextiles can be used in the protection of pipelines. Geotextiles are commonly employed as a protective layer to prevent damage to pipelines caused by external factors such as soil erosion, chemical exposure, and mechanical impacts. They act as a barrier between the pipeline and the surrounding soil, providing cushioning and reducing the risk of abrasion or puncture. Geotextiles also help to distribute the loads and stresses evenly, enhancing the overall stability and longevity of the pipeline system.

- Q: Is it possible to isolate permeated geotextiles and impervious geotextiles?

- Geotextile is permeable, and water, but the soil, from the filter effect, impermeable geotextile is geomembrane composite geotextile composite products, is impermeable and waterproof, I am specializing in the production of geotechnical materials,

- Q: Can geotextiles be used in the protection of culverts?

- Yes, geotextiles can be used in the protection of culverts. Geotextiles are permeable fabrics that can be placed around culverts to prevent soil erosion and filter out sediments. They provide additional support and stability to the culvert, protecting it from damage and prolonging its lifespan.

- Q: Small-scale geotextile and geotextile materials have no effect on environmental protection?

- The basic impact on the environment, I am specializing in the production of geotechnical materials

- Q: What are the key factors affecting the tensile strength of geotextiles?

- The key factors affecting the tensile strength of geotextiles include the type and quality of the material used, the manufacturing process, the thickness and weight of the geotextile, the orientation of the fibers, and the presence of any additives or coatings. Additionally, the installation and maintenance conditions, such as soil characteristics, temperature, moisture levels, and load distribution, can also impact the tensile strength of geotextiles.

Send your message to us

Plastic Grass Grid used for Lot Grass Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords