Color Aluminum Sheets With Mapp Gas for Different Usages

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Plain Aluminium Sheets for Different Usages

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminum Sheets are widely used in curtain walls, roofing, decoration, boats, airframes, instrument panels, etc.

2.Main Features of Plain Aluminium Sheets for Different Usages

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

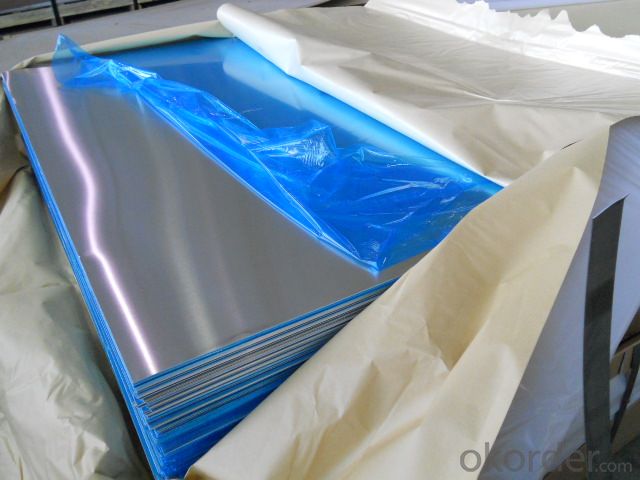

3. Plain Aluminium Sheets for Different Usages Images

4.Specification of Plain Aluminium Sheets for Different Usages

Alloy | AA1050,AA1060, AA1070, AA1100 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-500mm |

Width: | 10mm- 2200mm |

Standard: | GB/T3880-2006, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

5.FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put orderin production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium Coils?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Are aluminum sheets suitable for welding?

- Yes, aluminum sheets are suitable for welding.

- Q: why is it gd and what are common aluminium compounds??? thx

- Where aluminium is the third most common element on the planet (after oxygen and hydrogen), it is also the most used element on the planet, everything from pull tabs on soda cans to girders used in construction. Car parts, dog tags, pots and pans, it is everywhere. 95% of aluminium survives recycling, so when you recycle 1,000 can's (or return for deposit in 13 states), it is back on the shelves in the form of 950 new cans in just 6 weeks. As aluminium is a very difficult metal to seprate from other ores such as bauxite, recycling both protects the enviroment by slowing mining, and stabelizing the economy. Its not just a win-win, it can also be quite profitable even with the current low prices for aluminium on the markets.

- Q: I'm trying to use as little aluminum as possible as it can be related to health problems, and I'm just trying to be a little more careful. I just bought the Emerilware pro-clad pot and pan set, and it's stainless steel but says Emerilware Pro-Clad is constructed with an aluminum core bonded between two layers of stainless steel ideal for... Therefore, I'm still cooking with aluminum. Is it safer since it's between 2 pieces of stainless steel? Does any stainless steel cookware not use aluminum? Thanks.

- Aluminum and titanium are lighter, but they are easier to scratch (due to non-stick coatings) and do not hold heat as well. Stainless steel is more durable and distributes heat better. You can also clean it with sand or ice without having to worry about scratching it. If you are going to fry with it, you will need oil since the food will stick without it. When I go ultra light, I use a jet boil with a titanium pot to boil water for cooking. When I want to go gourmet, I use the GSI stainless steel set.

- Q: Do 101 aluminum sheets have any specific fire resistance properties?

- Indeed, specific fire resistance properties are possessed by a total of 101 aluminum sheets. With a melting point of 660 degrees Celsius (1220 degrees Fahrenheit), aluminum can endure high temperatures before the onset of melting. Furthermore, due to its low combustion point, aluminum does not easily ignite. In the event of a fire, the aluminum sheets serve as a barrier that hinders the spread of flames. Furthermore, the burning of aluminum results in the formation of a protective oxide layer on its surface, which effectively impedes the advancement of the fire. Nevertheless, it is important to acknowledge that although aluminum exhibits fire-resistant characteristics, it is not entirely impervious to fire and can still suffer damage or deformation when subjected to intense heat.

- Q: Is it suitable to use aluminum sheets as roofing materials in areas with high temperatures?

- <p>Yes, aluminum sheets can be used for roofing materials in hot climates. Aluminum has a high thermal conductivity, which means it can quickly dissipate heat, helping to keep buildings cooler. It also has excellent resistance to corrosion, which is beneficial in areas with high humidity or salt air. Additionally, aluminum is lightweight, easy to install, and can be recycled, making it an environmentally friendly option. However, it's important to ensure proper ventilation and insulation to maximize its performance in hot climates.</p>

- Q: This question asks for a list of adhesive types that are suitable for bonding aluminum sheets. It is important to provide a variety of options to give a comprehensive answer.

- <p>There are several types of adhesives used for bonding aluminum sheets together, including epoxy resins, which offer strong adhesion and resistance to heat and chemicals; polyurethane adhesives, known for their flexibility and durability; acrylic adhesives, which provide good adhesion and are easy to use; cyanoacrylates or 'super glues,' which bond quickly and are great for small, precise applications; and silicone adhesives, which are excellent for high-temperature applications and offer flexibility. Each type has its own advantages and is chosen based on the specific requirements of the bonding task, such as strength, flexibility, and resistance to environmental factors.</p>

- Q: This question asks for an explanation of the various types of coatings applied to aluminum sheets that are used outdoors.

- <p>Aluminum sheets used for exterior applications are often coated to enhance their durability, weather resistance, and aesthetic appeal. The different types of coatings include: 1. Anodizing, which creates a protective oxide layer on the aluminum surface. 2. Powder coating, a dry finishing process that provides a uniform and durable finish. 3. PVDF (Polyvinylidene Fluoride) coating, known for its excellent resistance to UV rays and chemicals. 4. Fluorocarbon coatings, which offer superior resistance to weathering and color retention. 5. Electrolytic coating, which involves the application of a thin protective layer through an electrochemical process. Each coating type has specific properties that make it suitable for different exterior applications and environmental conditions.</p>

- Q: Are the aluminum sheets suitable for manufacturing consumer goods?

- Yes, aluminum sheets are suitable for manufacturing consumer goods. Aluminum is a lightweight, strong, and malleable material that can be easily formed into various shapes and sizes. It has excellent corrosion resistance, which makes it ideal for products that may be exposed to moisture or other harsh conditions. Additionally, aluminum is highly recyclable, making it an environmentally friendly choice. Its aesthetic appeal, durability, and versatility make aluminum sheets an excellent option for manufacturing consumer goods such as kitchen utensils, appliances, furniture, packaging materials, and automotive parts.

- Q: Can the aluminum sheets be used in the construction industry?

- Certainly, the construction industry can make effective use of aluminum sheets. Aluminum proves to be a highly adaptable and lightweight material, offering numerous advantages for construction purposes. Its resistance to corrosion makes it especially suitable for outdoor structures and buildings. Roofing, siding, window frames, doors, and other architectural components often incorporate aluminum sheets. Moreover, aluminum's exceptional strength-to-weight ratio enables the creation of sturdy and efficient structures. Its malleability also facilitates easy fabrication and shaping into various forms, allowing for imaginative and groundbreaking designs in construction projects. Overall, aluminum sheets remain a widely favored choice in the construction industry due to their enduring nature, adaptability, and aesthetic appeal.

- Q: Can aluminum sheets be used for architectural applications?

- Architectural applications can definitely make use of aluminum sheets. Aluminum, being a lightweight and versatile material, offers numerous advantages for architectural projects. It possesses durability, resistance to corrosion, and the ability to withstand extreme weather conditions, making it an ideal choice for different architectural applications like roofing, cladding, facades, windows, doors, and decorative elements. The availability of aluminum sheets in various thicknesses, finishes, and colors allows architects and designers to achieve their desired aesthetic while maintaining structural integrity. With the material's flexibility in being easily shaped, bent, and formed into complex designs, architects are provided with creative freedom and flexibility. Aside from its aesthetic appeal, aluminum is also an environmentally sustainable choice for architectural applications. It is highly recyclable, contributing to a high recycling rate and promoting eco-friendly options. The use of aluminum sheets in architectural projects helps in reducing the carbon footprint and promoting sustainable design practices. Moreover, aluminum sheets offer excellent thermal and acoustic properties that contribute to energy efficiency and sound insulation in buildings. The material aids in reducing energy consumption and enhancing occupant comfort, making it an attractive option for architects and building owners. In conclusion, the versatility, durability, sustainability, and aesthetic appeal of aluminum sheets make them a popular choice for architectural applications. They provide numerous benefits and can be utilized in various ways to create stunning architectural designs while ensuring long-lasting performance.

Send your message to us

Color Aluminum Sheets With Mapp Gas for Different Usages

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords