Color Aluminum Sheets with Mapp Gas - Orange Pattern Embossed and PE Painted Aluminum Coils

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Orange Pattern Embossed and PE Painted Aluminum Coils

We professionally produce stucco embossed and coated aluminum coils, which are widely used in refrigerators, ice-boxes, cold storage, freezer, etc.

Stucco embossed and coated aluminum sheets look more beautiful and better at strength and rigidity than normal aluminum coils.

We normally use 3105, H44 as base coils. Specification of our stucco embossed and color coated aluminium coils: thickness 0.2-0.6mm, width less than 1600mm. As for coating, we normally use PVDF coating, PE coating, etc. We can adjust coating as per customers’ requirements.

2. Main Features of Orange Pattern Embossed and PE Painted Aluminum Coils

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

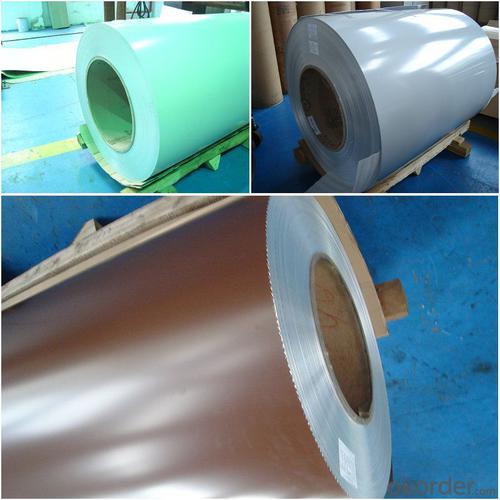

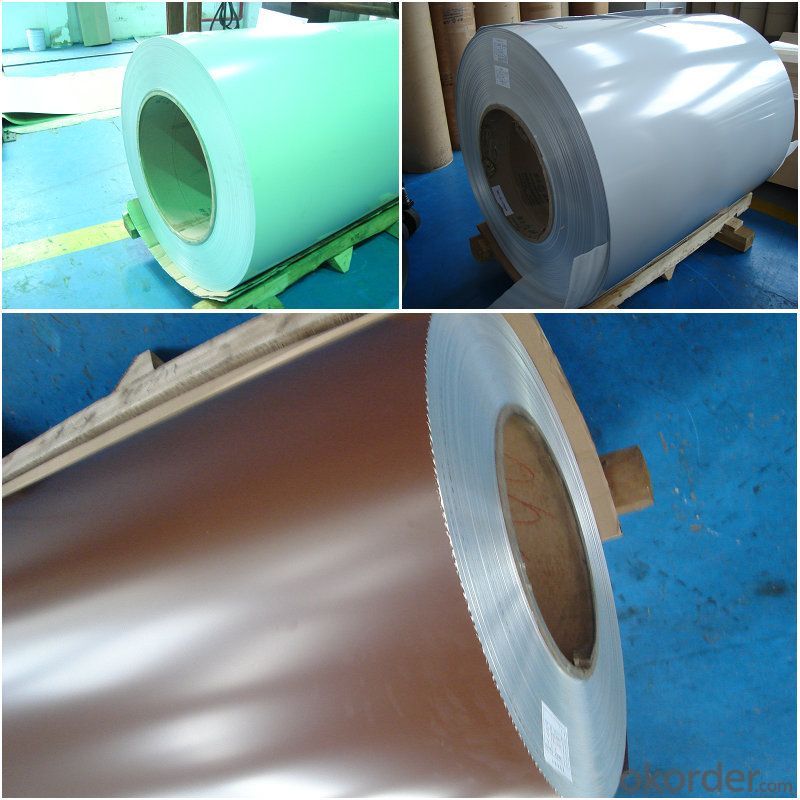

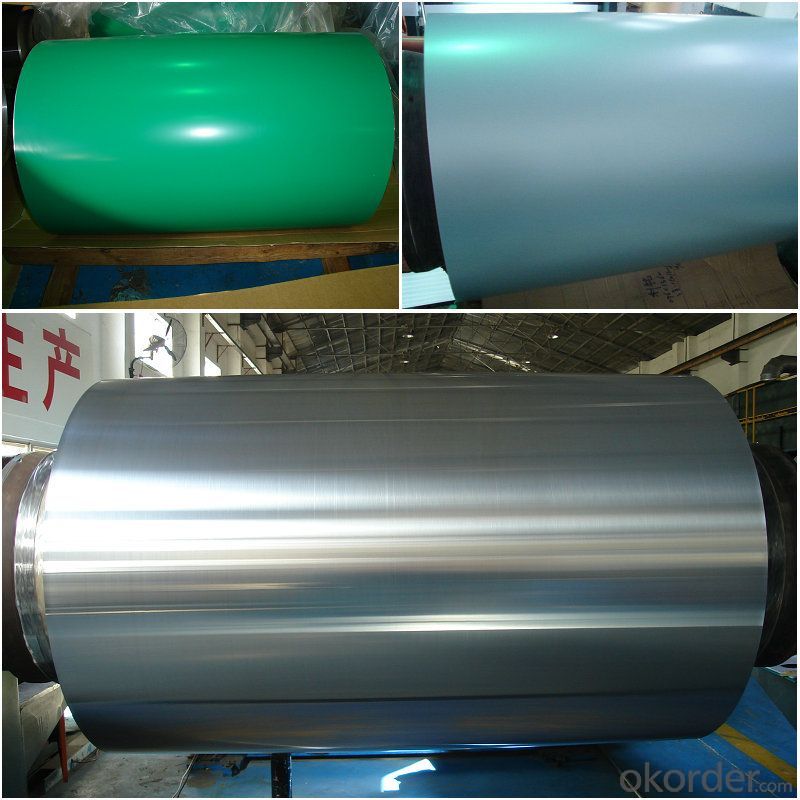

3. Orange Pattern Embossed and PE Painted Aluminum Coils Images

4. Specification of Orange Pattern Embossed and PE Painted Aluminum Coils

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: What is the difference between aluminum sheet and aluminum curtain wall? The cost is high!

- Composite aluminum plate is also called aluminum composite plate,The aluminum composite plate and aluminum sheet belong to curtain wall decoration materialThe difference between the two liesThe aluminum sheet is also called the pure aluminum sheet, and the single aluminum plate is coated with decorative paint on the aluminum plate surface,Aluminum composite plate is two layers of relatively thin and some also coated with aluminum decorative paint, and a middle plastic or honeycomb core, corrugated core, fireproof core plate composite. Contains aluminium composite panel, aluminum honeycomb board, aluminum composite corrugated board, aluminum composite wood plate, aluminum plate with the stone composite.According to the raw material composition, the aluminum single board price will be higher

- Q: This question asks for methods to prevent rusting on aluminum sheets during the installation process.

- <p>To prevent rusting on aluminum sheets during installation, ensure that the aluminum is of high quality and free from impurities. Keep the surface clean and dry at all times, avoiding contact with corrosive materials. Use appropriate protective coatings or sealants that are compatible with aluminum. Avoid scratches or dents that can expose the metal to moisture. Store aluminum sheets in a dry place before installation. During installation, handle the sheets carefully to avoid damage. Regularly inspect and maintain the aluminum sheets to catch any signs of corrosion early.</p>

- Q: What is the tensile strength of aluminum?

- The tensile strength of aluminum varies depending on the specific alloy and temper, as well as the manufacturing process. However, on average, the tensile strength of aluminum ranges from around 70 to 700 MPa (megapascals). This makes aluminum a relatively strong material compared to other non-ferrous metals. It is important to note that the tensile strength can also be influenced by factors such as the thickness and shape of the aluminum component, as well as any heat treatment it has undergone. Therefore, it is always recommended to consult specific data sheets or engineering references for accurate and precise information regarding the tensile strength of a particular aluminum alloy.

- Q: Is the value of specific heat capacity of aluminium higher or lower than the standard value? Why?

- RE: Specific heat capacity of aluminium...? Is the value of specific heat capacity of aluminium higher or lower than the standard value? Why?

- Q: the aluminium pull tabs are in a jucy juice bottle

- 82% okorder /

- Q: Can aluminum sheets be an alternative to stainless steel?

- Yes, aluminum sheets can be an alternative to stainless steel in certain applications. Aluminum is generally lighter, more affordable, and has better thermal conductivity compared to stainless steel. However, stainless steel offers superior corrosion resistance and strength, making it more suitable for certain industries like food processing or marine environments. The choice between aluminum and stainless steel depends on the specific requirements and constraints of the project.

- Q: Is it possible to use aluminum sheets for creating roofing tiles?

- <p>Yes, you can use aluminum sheets to make roofing tiles. Aluminum is a popular material for roofing due to its durability, lightweight, and resistance to corrosion. It can be shaped into various styles and sizes to mimic traditional roofing materials like clay or slate. Aluminum roofing tiles are also known for their energy efficiency, as they reflect heat and can help reduce cooling costs. However, it's important to ensure that the aluminum sheets are of good quality and installed correctly to achieve the desired performance and longevity.</p>

- Q: Are the aluminum sheets suitable for manufacturing electrical busbars?

- Indeed, electrical busbars can be manufactured using aluminum sheets. The remarkable electrical conductivity and lightweight nature of aluminum render it a preferred option for busbars. It effectively carries substantial electrical currents and boasts low resistance, making it exceptionally suitable for transporting electricity in power distribution networks. Moreover, aluminum sheets can be effortlessly manipulated and molded into diverse forms and dimensions, granting the opportunity for personalized designs and streamlined integration into electrical systems.

- Q: Is it feasible to recycle aluminum sheets and what factors contribute to its recyclability?

- <p>Yes, aluminum sheets can be recycled easily. Aluminum is one of the most recycled materials due to its lightweight, durability, and the energy efficiency of the recycling process. The recycling of aluminum requires only 5% of the energy needed to produce new aluminum from raw materials. Additionally, aluminum can be recycled indefinitely without losing its properties, making it an environmentally friendly choice. Proper sorting and collection systems are crucial for efficient recycling, and the demand for recycled aluminum is high in various industries, further facilitating its recycling process.</p>

- Q: Is it possible to use aluminum sheets as a material for exterior wall covering?

- <p>Yes, aluminum sheets can be used for exterior cladding. They are known for their durability, resistance to corrosion, and low maintenance requirements. Aluminum is lightweight, which makes it easier to install compared to heavier materials. It also has good thermal properties, helping to insulate buildings. Additionally, aluminum can be coated with various finishes, allowing for a wide range of aesthetic options. However, it's important to ensure proper installation and sealing to prevent water infiltration and to maintain the cladding's performance over time.</p>

Send your message to us

Color Aluminum Sheets with Mapp Gas - Orange Pattern Embossed and PE Painted Aluminum Coils

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords