Perforated Aluminum Baking Sheets - Building Material Wall Panel ACP Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Building Material Wall Panel ACP Aluminum Sheet Description:

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above. 3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment

2.Main Features of Building Material Wall Panel ACP Aluminum Sheet :

Reasonable and stable chemical composition

Accurate tolerance

Nice mechanical property

Standards: EN, ASTM and EN

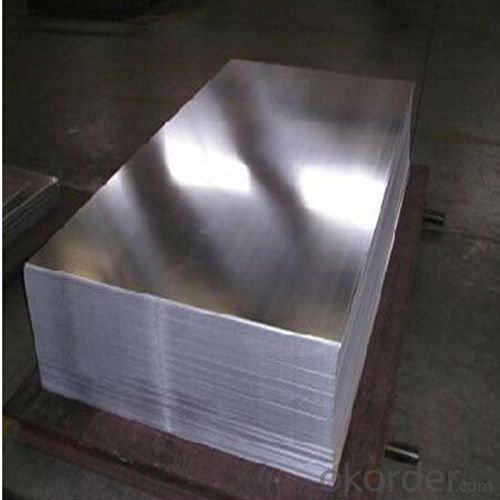

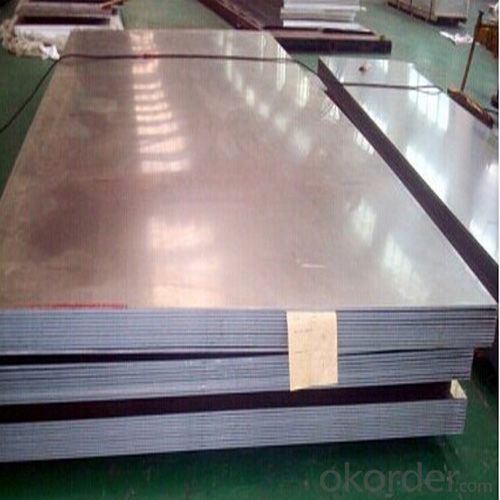

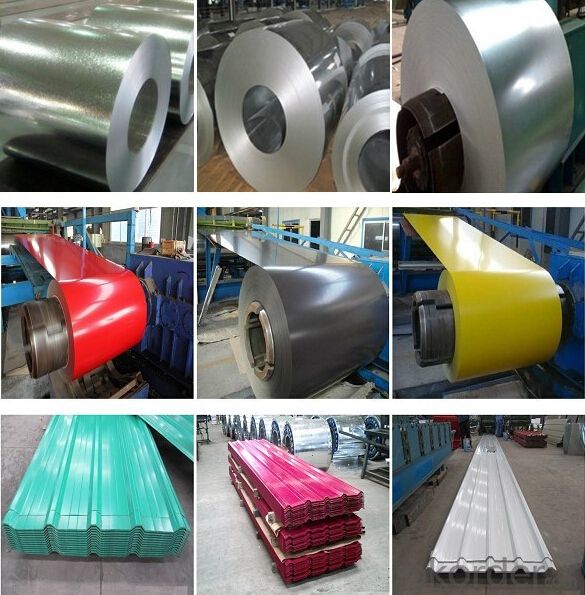

3.Building Material Wall Panel ACP Aluminum Sheet Images:

4. Building Material Wall Panel ACP Aluminum Sheet Specification:

1. | Item | Aluminum coil/ Aluminum strip,1070 aluminium coil | |

2. | Standard | ATSTM B209, JIS H4000-2006,GB/T3190-2008,GB/T3880-2006, etc. | |

3. | Material | 1000 Series:1050,1060,1080,1100,1435,etc. | |

2000 Series:2011,2014,2017,2024,2A12,2A16,2A06,etc. | |||

3000 Series:3002,3003,3004,3104,3204,3030,3A21,etc. | |||

5000 Series:5005,5025,5040,5052,5056,5083,5A05,etc. | |||

6000 Series:6003,6060,6082,6083,6063,6061,etc. | |||

7000 Series:7003,7005,7050,7075,etc. | |||

4. | Specifications | Thickness | 0.01mm~20mm |

Width | 10mm~2000mm | ||

Length | or as required | ||

6. | Surface | Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc. | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: This question asks about the various colors and finishes that can be applied to aluminum sheets.

- <p>Aluminum sheets are available in a wide range of colors and finishes, offering versatility for various applications. Common colors include silver, white, black, and bronze, but they can also be anodized or painted to achieve virtually any color. Finishes can be smooth, brushed, or embossed, with options like matte, satin, and gloss. Additionally, there are specialty finishes like mirror-like polished, hammered, and wood grain textures. The choice of color and finish depends on the specific requirements of the project, such as aesthetics, durability, and resistance to environmental factors.</p>

- Q: Can aluminum sheets be perforated?

- Indeed, it is possible to perforate aluminum sheets. Perforating entails either punching holes or generating a pattern of holes in a material. Aluminum, being a flexible and adaptable metal, can be easily perforated through a variety of techniques like punching, drilling, or laser cutting. The perforation of aluminum sheets can have numerous applications, including facilitating airflow, reducing weight, improving aesthetics, or constructing filtration systems. The dimensions, form, and layout of the perforations can be tailored to satisfy particular demands and design preferences. In summary, perforating aluminum sheets can effectively enhance their functionality and visual allure.

- Q: why is aluminium used instead of copper for high voltage electrical cables????

- All of the earlier answers are correct and the first one is very good but nobody mentioned the fact that aluminium does not have much tensile strength, and that as a result of this, some high voltage aluminium cables have a steel cable in the centre to give them the required tensile strength. Aluminium bus-bars are very popular in low voltage work because they do not need to be flexible or possess much tensile strength but yet provide the benefits of being light and cheap.

- Q: What are the different forming methods for aluminum sheets?

- The different forming methods for aluminum sheets include rolling, stamping, deep drawing, bending, and stretch forming. Rolling involves passing the aluminum sheet through a series of rollers to reduce its thickness and increase its length. Stamping uses a die to shape the sheet by applying pressure. Deep drawing involves pulling the sheet into a die cavity to create a deep and complex shape. Bending is used to create curves and angles in the sheet by applying force. Stretch forming stretches the sheet over a die to create a contoured shape.

- Q: how many protons,nuetrons, and electrons are in aluminum?

- Aluminum is from group 3 and there for has 3 electrons in its outer shell and desires 5 to fill it. it is going to react with any aspects from group 5 that desire aluminum's 3 electrons.

- Q: What are the common applications of aluminum sheets in construction?

- Aluminum sheets have various applications in the construction industry due to their unique properties and versatility. Some of the common applications of aluminum sheets in construction include roofing, siding, and cladding. Aluminum sheets are lightweight yet durable, making them ideal for roofing applications as they can withstand harsh weather conditions, such as strong winds and heavy rainfall, without corroding or deteriorating. In siding applications, aluminum sheets are commonly used due to their ability to resist rust and corrosion. They provide an aesthetically pleasing finish to buildings, enhancing their overall appearance. Additionally, aluminum sheets can be easily shaped and bent to fit the desired design, making them suitable for curved or intricate architectural designs. Cladding is another common application of aluminum sheets in construction. Aluminum cladding is used to cover the exterior walls of buildings, providing insulation and protection against weather elements. It helps to reduce the energy consumption of buildings by acting as a thermal barrier, keeping the interior cool in summer and warm in winter. Aluminum cladding is also fire-resistant, making it a safe choice for construction projects. Moreover, aluminum sheets are frequently used in the construction of windows and doors. Their lightweight nature makes them easy to handle and install, while their strength ensures durability and longevity. Aluminum sheets can be powder-coated or anodized, allowing for a wide range of color options to suit different architectural styles and preferences. Overall, the common applications of aluminum sheets in construction encompass roofing, siding, cladding, windows, and doors. Aluminum's lightweight, durable, and corrosion-resistant properties make it an excellent choice for various construction projects, providing both functional and aesthetic benefits to buildings.

- Q: Are the aluminum sheets suitable for manufacturing architectural ceiling panels?

- Yes, aluminum sheets are suitable for manufacturing architectural ceiling panels due to their lightweight properties, durability, and corrosion resistance. Additionally, aluminum sheets can be easily formed, cut, and fabricated into various shapes and designs, making them a popular choice for ceiling panels in architectural applications.

- Q: on the metal activity series, aluminum sits between magnesium and zinc, and all three sit above hydrogen. Explain why aluminum typically reacts only slowly with dilute acids even though both magnesium and zinc react rapidly

- Aluminum metal reacts with oxygen in the air to form a very tightly bonded aluminum oxide on its surface which slows the attack of acids trying to make contact with the aluminum atoms below the surface.

- Q: Are 101 aluminum sheets available in different finishes (e.g., brushed, polished)?

- Yes, 101 aluminum sheets are available in different finishes such as brushed and polished.

- Q: 1) Aluminum ore is not formed in Quebec (why not?) 2)but aluminum ore is smelted into aluminum in Quebec. Why?

- The okorder

Send your message to us

Perforated Aluminum Baking Sheets - Building Material Wall Panel ACP Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords