Webstaurant Aluminum Baking Sheets for Building Material - Aluminum Sheet/Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Alu Sheet/Coil for Building :

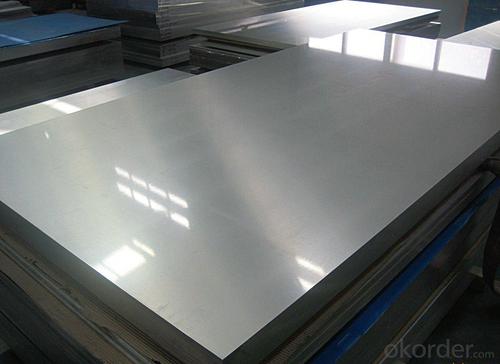

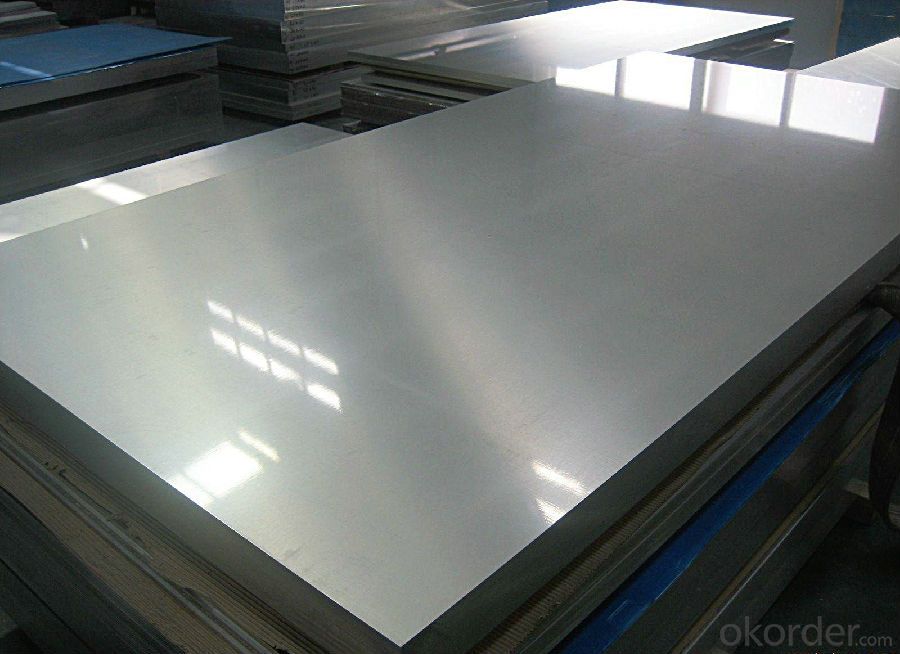

Alu Sheet/Coil for Buildingis designed for many field such as electronics, instruments, lighting decoration, packing industry, and house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel, aluminum composite pipe etc.. Alu Sheet/Coil for Buildingis hard and everlasting under the blazing sun. You can choose the alloys as your habitation and we will do our best to meet your requests.

2.Main Features of theAlu Sheet/Coil for Building:

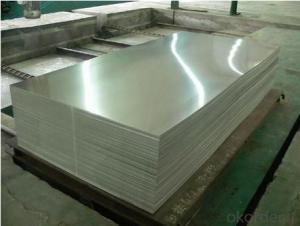

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

3. Alu Sheet/Coil for Building

Alloy: | AA1050, 1060, 1070, 1100, 3003, 3004, 3005, 3105, 5052, 5083, 5754, 8011, 8006 |

Temper: | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness: | 0.2-100mm |

Width: | 30mm-1700mm |

4. Production of Alu Sheet/Coil for Building

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: Are aluminum sheets suitable for automotive wheels?

- Automotive wheels can indeed be made from aluminum sheets. Aluminum, being both lightweight and strong, offers numerous advantages in the automotive industry. The incorporation of aluminum wheels can notably decrease the weight that is not supported by the suspension, thereby enhancing fuel efficiency and maneuverability. Moreover, aluminum possesses exceptional heat dissipation properties, which effectively prevent the brakes from overheating. Not to mention, aluminum wheels exude a sleek and stylish appearance, making them highly favored by car enthusiasts. It is worth mentioning, however, that not all aluminum sheets are suitable for automotive wheels. It is imperative to choose aluminum sheets of superior quality that have been specifically engineered to meet the stringent requirements of strength, durability, and heat resistance for automotive wheel applications.

- Q: What are the different thicknesses available for aluminum sheet?

- The different thicknesses available for aluminum sheet vary depending on the specific requirements and applications. Common thicknesses for aluminum sheet range from 0.016 inches (0.41 mm) to 0.25 inches (6.35 mm), with numerous options in between. The appropriate thickness is determined by factors such as the intended use, structural requirements, and aesthetic preferences.

- Q: Can aluminum sheets be anodized for aesthetic purposes?

- Yes, aluminum sheets can be anodized for aesthetic purposes. Anodizing is a process that creates a protective oxide layer on the surface of aluminum, which can be further enhanced with various colors and finishes for aesthetic appeal.

- Q: Explain how the use of aluminum sheets can impact the energy efficiency of a building.

- <p>Aluminum sheets can significantly affect a building's energy efficiency due to their excellent thermal conductivity and reflective properties. They can be used in building construction to form a barrier against heat transfer, reducing the need for heating and cooling. Additionally, aluminum's reflective surface can help in reflecting sunlight, thereby reducing heat gain in the building. However, if not properly insulated, aluminum's high conductivity can lead to heat loss, reducing energy efficiency. Therefore, the use of aluminum sheets in buildings often requires a balance between their heat-reflective and heat-conductive properties to optimize energy efficiency.</p>

- Q: Explain the pros and cons of utilizing aluminum sheets in the construction of car body panels.

- <p>Aluminum sheets offer several advantages for car body panels, such as reduced weight, which can improve fuel efficiency and handling. They also have high resistance to corrosion, enhancing the vehicle's durability. Additionally, aluminum is easier to recycle, contributing to environmental sustainability. However, there are downsides, including higher cost compared to steel, which can affect the vehicle's price. Aluminum is also less malleable, making it more challenging to repair after accidents, potentially leading to higher repair costs. Furthermore, aluminum's lower strength compared to steel can necessitate thicker panels to achieve the same structural integrity, which may offset some of the weight savings.</p>

- Q: which has more volume? a kg of gold or a kg of aluminum? please explain in physics terms

- Gold is a heavy metal and aluminum is very light. So aluminum would take up lots more space than an equal weight of gold, even if the aluminum was forged into a smaller size.

- Q: Are the aluminum sheets suitable for manufacturing automotive body panels?

- Indeed, automotive body panels can be manufactured using aluminum sheets. Aluminum, being a material that is both lightweight and robust, presents numerous advantages in the realm of automotive applications. Its high ratio of strength to weight enables enhanced fuel efficiency and superior overall vehicle performance. Furthermore, aluminum boasts exceptional corrosion resistance, rendering it suitable for enduring adverse environmental conditions. Moreover, its malleability and ease of manipulation facilitate the creation of intricate designs and shapes essential for automotive body panels. These attributes have established aluminum sheets as a highly favored option within the automotive industry for the production of body panels.

- Q: What is the maximum temperature aluminum sheets can withstand?

- The maximum temperature that aluminum sheets can withstand depends on several factors, including the alloy composition and thickness of the sheet, as well as the specific application and environment in which it is being used. Generally, pure aluminum has a melting point of around 660 degrees Celsius (1220 degrees Fahrenheit), but it begins to lose strength and stiffness at much lower temperatures. Most commercial aluminum alloys have higher melting points and can withstand higher temperatures. For example, 6061 aluminum alloy has a melting point of around 580 degrees Celsius (1076 degrees Fahrenheit), while 7075 aluminum alloy has a slightly higher melting point of around 640 degrees Celsius (1184 degrees Fahrenheit). However, it is important to note that the maximum temperature a sheet of aluminum can withstand without significant deformation or structural damage may be lower than its melting point. This is because aluminum's strength and mechanical properties degrade at elevated temperatures. In applications where aluminum sheets are subjected to high temperatures, it is crucial to consider the specific alloy and its thermal properties, as well as any potential changes in strength, hardness, or other relevant characteristics that may occur at elevated temperatures. Consulting material specifications, engineering guidelines, or seeking professional advice from metallurgical experts can provide more accurate and specific information regarding the maximum temperature capabilities of aluminum sheets for a particular application.

- Q: What are the different methods of surface preparation for adhesive bonding of aluminum sheet?

- There are several different methods of surface preparation for adhesive bonding of aluminum sheet. These methods are used to ensure a strong and durable bond between the adhesive and the aluminum surface. One common method is mechanical abrasion, which involves roughening the surface of the aluminum sheet using abrasive materials such as sandpaper or wire brushes. This creates a textured surface that improves the adhesion of the adhesive. Another method is chemical etching, which involves treating the aluminum surface with a chemical solution to remove any oxide layer and create a clean and reactive surface. This can be done using acids or alkalis, depending on the specific requirements of the adhesive. Some adhesives require a clean surface free from any contaminants, so a method called solvent cleaning can be used. This involves using solvents such as acetone or isopropyl alcohol to remove any grease, oil, or dirt from the surface of the aluminum sheet. In addition to these methods, there are also specialized techniques such as anodizing and chromate conversion coating. Anodizing involves creating a thick oxide layer on the surface of the aluminum through an electrolytic process, which improves the bonding properties. Chromate conversion coating, on the other hand, involves treating the aluminum surface with a chemical solution containing chromates, which creates a protective layer and enhances adhesion. Overall, the choice of surface preparation method depends on the specific requirements of the adhesive and the desired bond strength. It is important to carefully select and follow the appropriate method to ensure a successful adhesive bonding of aluminum sheet.

- Q: Are the aluminum sheets suitable for manufacturing heat exchangers?

- Yes, aluminum sheets are suitable for manufacturing heat exchangers. Aluminum is a lightweight and highly conductive material, making it an ideal choice for heat transfer applications. Its excellent thermal conductivity allows for efficient heat transfer, resulting in effective cooling or heating processes. Additionally, aluminum is corrosion-resistant, which is crucial for heat exchangers that come in contact with various fluids. The malleability and formability of aluminum sheets also make them easy to shape into the required designs for heat exchanger components. Overall, aluminum sheets offer several advantages for manufacturing heat exchangers, making them a suitable choice for this application.

Send your message to us

Webstaurant Aluminum Baking Sheets for Building Material - Aluminum Sheet/Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords