Perforated Aluminum Alloy Plate for Mould Electronics Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Alloy Plate for Mould Electronics Industry Description:

We can produce aluminum sheet,color aluminum sheet and plastic composite panel base material. They are widely used in construction and decoration, hardware and electric appliances manufacture, automobile manufacture and other industrial and civil purposes, such as electronic capacitor, rice cooker, refrigerator, computer casting, lamp shade, air-conditioner, cosmetics cover and box, air-conditioner radiator, inner container of disinfecting cabinet, ceiling board, automobile motherboard, cover board and top board, etc.

2.Main Features of Aluminum Alloy Plate for Mould Electronics Industry :

Easily cold worked and formed

Good welding characteristics

High Quality

Competitive Price

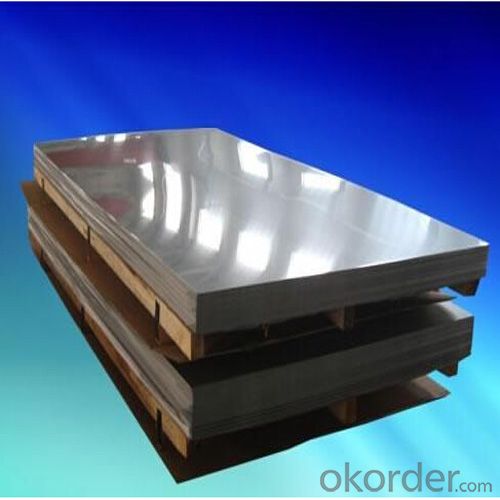

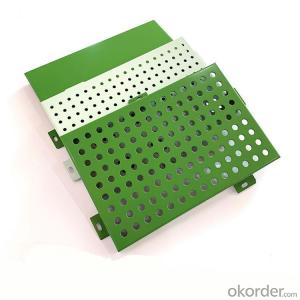

3. Aluminum Alloy Plate for Mould Electronics Industry Images:

4. Aluminum Alloy Plate for Mould Electronics Industry Specification:

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Are aluminum sheets suitable for outdoor use?

- Yes, aluminum sheets are suitable for outdoor use. Aluminum is a durable and corrosion-resistant material that can withstand various weather conditions, making it ideal for outdoor applications.

- Q: Can aluminum sheet be used for medical applications?

- Yes, aluminum sheet can be used for certain medical applications. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for various medical devices and equipment. For example, aluminum sheets can be used for manufacturing prosthetic limbs, braces, and orthopedic implants. Additionally, aluminum can be used in the production of medical instruments, such as surgical trays, sterilization containers, and imaging equipment. However, it is important to note that aluminum may not be suitable for all medical applications, as certain medical devices may require specific properties or materials to meet regulatory standards and ensure patient safety. Therefore, the use of aluminum sheet in medical applications should be determined on a case-by-case basis, considering the specific requirements and regulations of each application.

- Q: What are the different surface treatments for aluminum sheets to improve corrosion resistance?

- Aluminum sheets can be treated with several methods to greatly improve their resistance to corrosion. These treatments encompass: 1. Anodizing: Widely used, anodizing involves submerging aluminum in an electrolyte solution and applying an electric current. Consequently, a protective oxide layer forms on the surface, effectively enhancing corrosion resistance. 2. Chromate Conversion Coating: Also known as chemical film or chromating, this treatment immerses aluminum in a solution with chromate compounds. This creates a thin chromate layer serving as a barrier against corrosion. 3. Powder Coating: In this dry finishing process, a powdered polymer is sprayed onto the aluminum surface and then cured under heat. The result is a durable, corrosion-resistant coating that offers exceptional protection against environmental factors. 4. E-coating: Electrophoretic coating, or e-coating, is an immersion-based process where aluminum sheets are submerged in an electrically charged paint bath. The paint particles are attracted to the surface, creating a uniform and corrosion-resistant coating. 5. Cladding: By bonding a layer of a different metal, such as stainless steel or zinc, to the surface of aluminum sheets, cladding forms a protective barrier that shields against corrosion. 6. Organic Coatings: Applying organic coatings like acrylic or polyester paints to the aluminum surface forms an effective corrosion-resistant barrier. These coatings create a protective film that prevents moisture and corrosive substances from reaching the aluminum. It's worth noting that the choice of surface treatment depends on various factors, including the specific application, environmental conditions, and desired appearance. Consulting with professionals is advisable to determine the most appropriate treatment for a particular application, as some treatments may be better suited for certain industries or environments.

- Q: Can aluminum sheet be used for electrical enclosures?

- Yes, aluminum sheet can be used for electrical enclosures. Aluminum is a commonly used material in the electrical industry due to its excellent conductivity, corrosion resistance, and lightweight properties. It provides good shielding against electromagnetic interference and is easy to fabricate into various shapes and sizes for enclosures.

- Q: Are aluminum sheets suitable for aircraft manufacturing?

- Indeed, aircraft manufacturing finds aluminum sheets to be highly suitable. The aerospace industry extensively utilizes aluminum owing to its exceptional blend of qualities, encompassing its lightweight nature, robust strength, ability to withstand corrosion, and outstanding malleability. Such attributes render aluminum an optimal substance for constructing diverse aircraft elements, including fuselages, wings, and structural components. Furthermore, aluminum alloys can be effortlessly fused, facilitating efficient manufacturing procedures. In totality, aluminum sheets assume a pivotal function in aircraft manufacturing, substantially enhancing the aircraft's overall performance, durability, and safety.

- Q: Are there any formulators out there that have any ideas on putting together a cleaner that removes carbon (baked on grease) from an aluminum pan without attacking the meatal itself?? Ive been thinking about this problem for a while and would appriciate any ideas you guys might have. Thanks

- try GOJO hand cleaner with a Sung. you dont need to scrub hard and it will remove the baked on grease.

- Q: Is it feasible to use aluminum sheets for constructing exteriors of buildings in regions susceptible to earthquakes?

- <p>Aluminum sheets can be used for building exteriors in earthquake-prone areas, but they must be properly engineered and installed. Aluminum is lightweight and flexible, which can be advantageous in withstanding seismic forces. However, it's crucial to ensure that the aluminum is reinforced with a robust structural system that can distribute the forces during an earthquake. The design must also comply with local building codes and seismic regulations. It's recommended to consult with structural engineers and architects experienced in earthquake-resistant design to ensure the safety and durability of the construction.</p>

- Q: What is the reflectivity of aluminum sheets?

- Aluminum sheets possess a considerably high reflectivity, typically falling within the range of 80% to 90%. Such elevated reflectivity can be attributed to the sleek surface and distinctive characteristics of aluminum, enabling it to effectively bounce back light and other electromagnetic waves. Consequently, aluminum sheets find wide application in scenarios that necessitate heightened reflectivity, including the creation of reflective surfaces, solar panels, and mirrors. Furthermore, the reflectivity of aluminum can be augmented even more by employing a reflective coating or meticulously polishing the surface.

- Q: Are the aluminum sheets available in different grades?

- Yes, aluminum sheets are available in different grades. Aluminum is commonly used in various industries due to its lightweight, corrosion resistance, and strength-to-weight ratio. Different grades of aluminum sheets are designed to meet specific requirements for various applications. The most common grades include 1100, 3003, 5052, 6061, and 7075. Each grade has its own unique properties and characteristics, such as strength, formability, weldability, and machinability. The choice of grade depends on factors such as the intended use, environmental conditions, and desired properties of the finished product.

- Q: What are the advantages of using aluminum sheets?

- There are several advantages of using aluminum sheets in various applications. Firstly, aluminum sheets are lightweight, making them easy to transport and handle. This characteristic makes them ideal for industries where weight is a crucial factor, such as aerospace and automotive industries. Secondly, aluminum sheets have excellent corrosion resistance properties. They are naturally resistant to rust and can withstand exposure to harsh environmental conditions, including moisture, chemicals, and UV rays. This makes them highly durable and long-lasting, reducing the need for frequent maintenance and replacements. Furthermore, aluminum sheets are highly malleable and can be easily formed into different shapes and sizes. This flexibility allows for customization and versatility in design, enabling manufacturers to create complex structures and products. In addition, aluminum sheets have excellent thermal and electrical conductivity. They can efficiently dissipate heat and conduct electricity, making them suitable for applications in the electrical, heating, and cooling industries. Another advantage of using aluminum sheets is their aesthetic appeal. Aluminum has a sleek and modern appearance, making it a popular choice for architectural and interior design applications. It can be easily painted or coated to achieve different colors and finishes, further enhancing its visual appeal. Lastly, aluminum is a sustainable material. It is 100% recyclable and can be repeatedly melted and reformed without losing its properties. This makes aluminum sheets an environmentally friendly choice, contributing to the reduction of waste and carbon footprint. Overall, the advantages of using aluminum sheets include their lightweight nature, corrosion resistance, malleability, thermal and electrical conductivity, aesthetic appeal, and sustainability. These qualities make aluminum sheets a preferred material in various industries and applications.

Send your message to us

Perforated Aluminum Alloy Plate for Mould Electronics Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords