POLISHED ALUMINIUM PLATES FOR MOLD PRODUCTION

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description:Polished aluminium sheets 6061 for mold production

2. Our Strength:

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

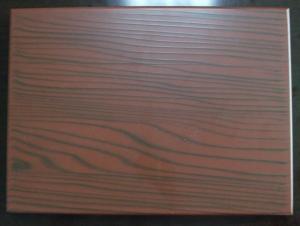

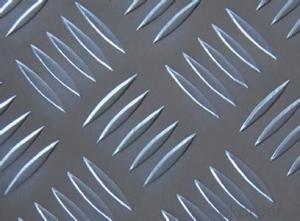

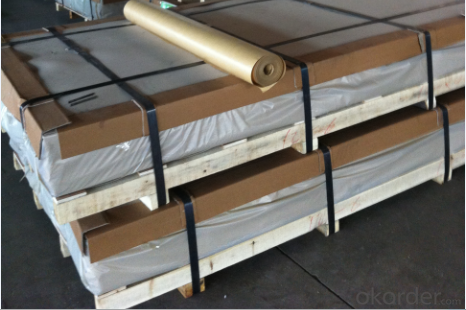

3. Image:

4. Common Specification

1000mm*2000mm, 1500*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 5 tons/each size.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet,

mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Can aluminum sheet be used for heat exchangers?

- Yes, aluminum sheet can be used for heat exchangers. Aluminum has excellent thermal conductivity and is lightweight, making it a suitable material for transferring heat efficiently in heat exchangers. Its corrosion resistance and durability also make it a popular choice in various heat exchange applications.

- Q: Can aluminum sheet be used for heat shielding?

- Indeed, heat shielding can be achieved by utilizing aluminum sheet. Due to its high thermal conductivity and exceptional heat dissipation characteristics, aluminum proves to be a proficient substance for applications pertaining to heat shielding. Furthermore, its capacity to reflect radiant heat renders it appropriate for deployment in thermal barriers and insulation systems. Moreover, the lightweight nature, resistance to corrosion, and ease of fabrication associated with aluminum sheet render it an economical option for heat shielding across diverse industries including aerospace, automotive, and electronics.

- Q: Can aluminum sheets be custom cut to specific sizes?

- Yes, aluminum sheets can be custom cut to specific sizes. Aluminum is a highly versatile material that can easily be cut and shaped to meet specific requirements. With the right tools and equipment, aluminum sheets can be accurately cut to any desired size, whether it's for industrial, commercial, or personal use. This flexibility allows for the customization of aluminum sheets to fit specific applications, making it a popular choice in various industries such as construction, automotive, and aerospace. Whether you need small or large aluminum sheets, they can be easily cut to the exact dimensions you require, ensuring a precise fit for your specific project or application.

- Q: Can aluminum sheets be used for decorative panels?

- Aluminum sheets are indeed suitable for decorative panels. Being a lightweight and versatile material, aluminum can be easily shaped, cut, and molded into various designs and patterns. Its sleek and modern appearance makes it a popular option for decorative purposes in both residential and commercial settings. Aluminum panels have a wide range of applications, including wall cladding, ceiling panels, room dividers, signage, and more. Moreover, aluminum is resistant to corrosion and weathering, making it suitable for both indoor and outdoor use. Additionally, aluminum panels can be personalized with different finishes, such as powder coating or anodizing, to enhance their visual appeal. In conclusion, aluminum sheets are an excellent choice for creating decorative panels due to their pleasing aesthetics, durability, and adaptability.

- Q: Can aluminum sheets be used for boat hulls?

- Yes, aluminum sheets can be used for boat hulls. Aluminum is a popular material choice for boat hulls due to its lightweight nature, high strength-to-weight ratio, and excellent corrosion resistance. Aluminum sheets are often used in boat construction to create hulls that are durable, sturdy, and capable of withstanding harsh marine environments. The versatility of aluminum allows for various fabrication techniques, making it suitable for different types of boats, including recreational boats, fishing boats, and even commercial vessels. Moreover, aluminum hulls require less maintenance compared to other materials, which makes them a cost-effective option for boat owners.

- Q: im doing a science project on aluminum and i need to know if aluminum is combustible or not. I was reading a website and they said that it reacts when its the right temperature? i really have no idea what the answer is please help! :)

- You're trying to make Thermite. Anarchists cookbook will help you - but you need Aluminum powder and mix it with some other ****... Regular aluminum will just melt

- Q: Can the aluminum sheets be used for manufacturing musical instruments?

- Yes, aluminum sheets can be used for manufacturing musical instruments. Aluminum is a lightweight and versatile material that offers several advantages for instrument manufacturing. It is known for its excellent sound transmission properties, which makes it suitable for creating resonant and vibrant tones in musical instruments. Additionally, aluminum is highly durable and resistant to corrosion, ensuring that the instruments will withstand the test of time. Many percussion instruments, such as cymbals and bells, are commonly made from aluminum sheets due to their ability to produce clear and rich sounds. Moreover, aluminum can also be shaped and formed into various instrument components, making it a popular choice for constructing brass instruments like trumpets and trombones. Overall, aluminum sheets are a viable option for manufacturing musical instruments and have been successfully utilized in the industry.

- Q: the coil is wrapped around the aluminium pipe will it effect the efficiency of the coil gun ?

- Yes, it absorbs most magnetic force generate by coil and turns it into useless current .

- Q: How do you prevent fingerprints on aluminum sheets?

- One way to prevent fingerprints on aluminum sheets is by wearing gloves while handling them. Additionally, regularly cleaning the sheets with a gentle, non-abrasive cleaner can help remove any existing fingerprints and prevent new ones from forming.

- Q: Can aluminum sheets be used for roofing?

- Yes, aluminum sheets can be used for roofing. Aluminum is a popular roofing material due to its durability, lightweight nature, and resistance to corrosion. It is commonly used in residential and commercial roofing applications.

Send your message to us

POLISHED ALUMINIUM PLATES FOR MOLD PRODUCTION

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords