PE Woven Tarpaulin with Sun-Resistant Factory

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.5

- Supply Capability:

- 1200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description for Tarpaulin

Materials:PP or PE

Regular size: 2x3m, 3x4m,3x5m, 4x5m, 4x6m, 5x8m, 6x8m, 6x10m, 2.5x3.6m, 3.6x5.4m, 5.4x7.2m, 7.2x9m, 10x50m. According to the requirements of customers....,

Mesh: 9x9 to 14x14

Width: 1.6 to 12m

Weight: 70 to 360gsm

Denier: 500D ~ 1500D

Color: various colors available

Length: no limit

Water, mildew and tear resistant, Double waterproof surfaces.Reinforced corner;

Rope in along edges for added strength,

For recreational vehicles, trucks, boats, construction sites, firewood.

Multi-purpose: truck cover, trailer cover, equipment cover, ground cover, emergency shelter, painting tarp, trailer awning, etc.

2. Fetures and Application:

sun-resistant,UV treated, lightweight, easy to fold, durable and other characteristics.

Tarpaulin is widely used for truck canopy,ship cover and cargo storage or transportation in mineral factories and ports, also can be used as tents in outside travel and calamities.The tarpaulin is to cover and protect the goods in the open air and avoid the goods get wet.

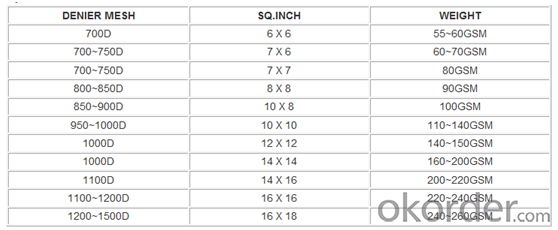

3. Specifications for Tarpaulin

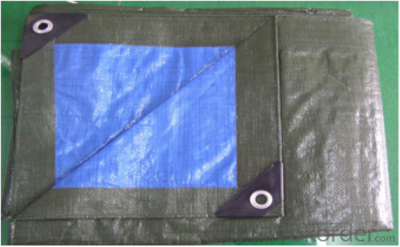

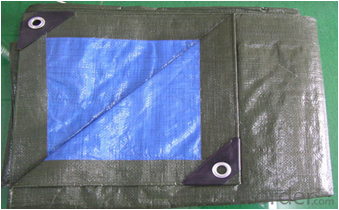

4. Photo for Tarpaulin

- Q: The cushion is usually in the housing which parts

- First of all, the foundation refers to the basis of the ground below, the cushion is generally below the base, the base should be there, if the sewage treatment station, then you look at the sewage pool, the bottom of the pool should also have it

- Q: Roof waterproof mattress should play the number of centimeters appropriate

- Roof waterproofing can not use a single waterproof material, must be rigid and flexible combination of construction, flexible waterproof stretch is good, a little bit of settlement or deformation will not damage the waterproof layer. Rigid waterproof (ie mortar waterproofing agent) waterproof at the same time, can play a protective role, waterproof layer is not easy to be destroyed.

- Q: When the cushion is used, the thickness of the protective layer is not less than ()

- Master roof: the general use of 40 thick C20 reinforced fine stone concrete protection.

- Q: Why do the basics of the cushion waterproofing

- As for the bottom of the bar thickness of the protective layer is generally 4cm, but if the basic floor of the concrete label is relatively high, the protective layer can be appropriately reduced.

- Q: Is the raft cushion waterproofing full of the cushion?

- As for the bottom of the bar thickness of the protective layer is generally 4cm, but if the basic floor of the concrete label is relatively high, the protective layer can be appropriately reduced.

- Q: Basement cushion waterproof

- Five, how the basement moisture: 1, moisture-proof material This is the decoration in the attention of the problem, the basement is relatively humid place, so when we should pay attention to the decoration, the choice of wallpaper, tiles and other moisture-proof effect of better decoration materials, and other basement ceiling, floor, walls are To be the best waterproof. 2, ventilation and moisture Strengthen the air circulation on the moisture is more helpful, can effectively reduce the indoor moisture content. 3, electrical dehumidification If you run into the rainy weather, outdoor air humidity is relatively high, it is not suitable for long ventilation, you can use the exhaust fan, air conditioning or dehumidifier and other machines for indoor dehumidification. 4, desiccant dehumidification In addition to the use of a variety of electrical dehumidification can also be placed some moisture damp dehumidification effect of small items, such as desiccant, charcoal and other indoor moisture, but the desiccant is a service life, the general need for frequent replacement. 5, to warm moisture Installation of warmth is also one of the effective means of underground moisture protection, to warm the basement room temperature can be maintained at a certain temperature can keep the room dry and not wet, but pay attention to the temperature is not too high will cause the room is too dry, Comfortable.

- Q: What is the relationship between the cushion and the ring beam?

- Cushion is plain concrete or asphalt concrete (for groundwater soil corrosive strong site). Is located below the ground, in order to prevent the foundation or the concrete beam pouring when the excessive loss of water caused by defects set. The purpose is to ensure the quality of concrete, increase the durability of underground components

- Q: Large area ground concrete cushion seam Why is the separation of joints generally concrete

- hird, the relevant parts Different types of rigid waterproof layer separation spacing in addition to meet the calculation needs, but also in the following parts set sub-grid joints. 1. The deformation of the roof structure sensitive parts; 2. Roof and roof drainage direction changes; 3. The junction of the waterproofing layer and the protruding roof structure; 4. Under normal circumstances, each bay load-bearing walls should be set sub-grid seam. 5. Between the waterproof layer and the load-bearing or non-load-bearing parapet or gable should be set sub-grid joints, and in the node structure for proper treatment.

- Q: How to build a fine stone concrete cushion?

- Reduce ground cracking, plus steel mesh. Reinforced mesh, should be placed in the middle of the concrete, because the protective layer of concrete thick Fang generally only 5CM thickness, so the middle is the best.

- Q: Maintenance time of the cushion on the roof of the building

- Concrete watering maintenance time: the use of Portland cement, ordinary Portland cement or slag Portland cement mixed with concrete, not less than 7d;

Send your message to us

PE Woven Tarpaulin with Sun-Resistant Factory

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.5

- Supply Capability:

- 1200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords