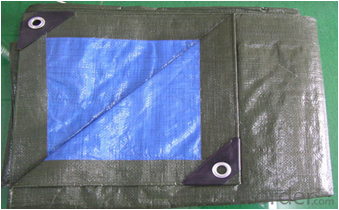

PE Tarpaulin with Sun-Resistant Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.7

- Supply Capability:

- 1200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description for Tarpaulin

Material: PE, Polyethylene

* Inner Fabric HDPE Woven, Both Sides LDPE Laminated

Specification:

* Denier: 750 ~3,000 Denier

* Density/sq. inch: 3x3 or 4.5x4.5

* Color: any color available

* Weight: 55g/SQ.M ~ 280g/SQ.M

*Width Without Joint:1'-8'(0.3M-2.44M)

*Width with Joint:8'-100'(2.44M-30M)

*Printing: three color printing available.

*Size: 2x3m, 3x4m, 4x6m … any size available

*UV. FR TREATMENT available upon request

* PE fabrics both sides laminated, reinforced by P.P rope in hem on all around edges,

* aluminum eyelets every 1 meter or 3' or 1yd interval(30cm, 50cm interval also available),

*Packing: each pc in a polybag with your insert paper then proper pcs in a carton box packing or same color bale packing.

Loading Container:

*Tarpaulin Rolls: Packed On Paper Tubes, Warped In The Same Tarpaulin Sheet As Inner Product. 20'GP Can Load 18 Ton.

*Ready Made: Each Piece Put In Poly Bag With One Label Insert

Bale packing: Packed In Bales Made Of The Same Tarp As Inner Tarps 20'GP Can Load 12 Ton , 40'HQ Can Load 25 Ton.

Carton packing: Packed In Cartons. 20'GP Can Load 9 Ton , 40'HQ Can Load 22 Ton.

Application Field:

Industrial - Covers for general use, scaffoldings in construction sites, underground sheets, covers for trucks, cars, boat, containers, warning tapes, covers for materials, roofs, road repair sites, fences,

Agricultural - Covers for timber, hay, cotton and all kinds of crops covers for drying crops

Home/Garden use(D.I.Y) - Covers for garden, backyard use Covers for furniture Gazebo tents, dining canopies, swimming pool covers

2. Fetures and Application:

Sun-resistant,UV treated, lightweight, easy to fold, durable and other characteristics.

Tarpaulin is widely used for truck canopy,ship cover and cargo storage or transportation in mineral factories and ports, also can be used as tents in outside travel and calamities.The tarpaulin is to cover and protect the goods in the open air and avoid the goods get wet.

3. Specifications for Tarpaulin

Product | |

Material | PP or PE (Inner HDPE Woven Fabric, LDPE laminated both sides ) |

Weight | 55 GSM / SQ.M ~ 300 GSM / SQ.M |

Width | 2 meter or 4 meter withou joint. Available for wider fabric by heat sealing. Or as the client's requirment |

Denier | 500 ~ 3000 Denier |

Lenght | 50 meter to 200 meter |

Density / sq.inch : | 7X6, 7X7, 8X7, 8X8, 10X8, 10X10, 12X12, 14X14, 16X16 ( 2x3m, 3x4m,3x5m, 4x5m, 4x6m, 5x8m, 6x8m, 6x10m, 2.5x3.6m, 3.6x5.4m, 5.4x7.2m, 7.2x9m, 10x50m.) |

Mesh | 8x8 9x9 10x10 11x11 12x12 14x14 |

Making | a. All edges with PP rope in hem; |

4. Photo for Tarpaulin

- Q: Can the cushion on the prefabricated board floor be dug?

- Prefabricated board floor layer of cement layer is not called the cushion, should be called leveling layer, this layer can be removed, but be careful not to damage the prefabricated plate.

- Q: Foam concrete for the roof cushion generally do much bulk ah

- Foam concrete density grade is generally 300-1800kg / m3, commonly used foam concrete density grade 300-1200 kg / m3,

- Q: Basement cushion waterproof

- Fourth, improve the waterproof performance: 1, Aggregate graded concrete, is the use of different aggregates of the aggregate and improve the content of cement mortar in the concrete, so that the mortar is filled between the aggregate, thus blocking the aggregate is not dense between the seepage channel , Improve water resistance; 2, plus concrete, is added in the concrete air conditioner or dense agent to improve the impermeability.

- Q: Can the floor tiles be removed from the cement mats on the prefabricated board floor?

- Prefabricated board floor layer of cement layer is not called the cushion, should be called leveling layer, this layer can be eradicated, but should pay attention not to damage.

- Q: What is the relationship between the cushion and the ring beam?

- Cushion is plain concrete or asphalt concrete (for groundwater soil corrosive strong site). Is located below the ground, in order to prevent the foundation or the concrete beam pouring when the excessive loss of water caused by defects set. The purpose is to ensure the quality of concrete, increase the durability of underground components

- Q: What is the waterproof layer and the waterproof cushion in the tile roof?

- In the tile roof, to wait for the waterproof layer after the dry layer, or prone to the phenomenon of wall off. Waterproof layer set and standard construction methods: to be painted 2 to 3 times, or should be added fiberglass cloth, and each brushing the thickness of the cured material shall not be less than 1 mm, and should be completely dry (about 5-8 Hour) and then the next construction. After brushing, but also in the paint waterproof layer to do a mortar protective layer, and finally paste the tile.

- Q: How to build a fine stone concrete cushion?

- The cushion is primarily responsible for the load coming from the surface and passes the load evenly to the structural or base.

- Q: Basement floor mattress dry to what degree can do coil waterproof?

- First, the basement moisture treatment structure is usually: first in the basement wall outer surface wiping 20mm thick 1: 2 waterproof mortar, basement walls should be used cement mortar masonry, gray seam must be full; and in the basement floor and the first Floor floor is divided into two walls of the level of moisture-proof layer. The outer wall of the basement wall should be tampered with the soil with poor permeability.

- Q: Why calculate the amount of time to count a lot of cushion ah

- In the building construction refers to the base is located below the cushion sometimes also served as grassroots. With the cushion, in the above work is convenient, clean, especially the mold, bar reinforced, pouring concrete and other processes, will not be affected by the basic earth pollution. Set the place where the cushion is generally based, floor, roof (slope) and so on.

- Q: Maintenance time of the cushion on the roof of the building

- Concrete watering maintenance time: the use of Portland cement, ordinary Portland cement or slag Portland cement mixed with concrete, not less than 7d;

Send your message to us

PE Tarpaulin with Sun-Resistant Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.7

- Supply Capability:

- 1200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords