Water and Vapor Insulation Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20' CONTAINER m.t.

- Supply Capability:

- 500000 Square Meter/Square Meters per Week m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Water and Vapor Insulation Membranes have been used in buildings for many years now and, more recently, in cold pitched roof constructions without traditional eaves ventilation.

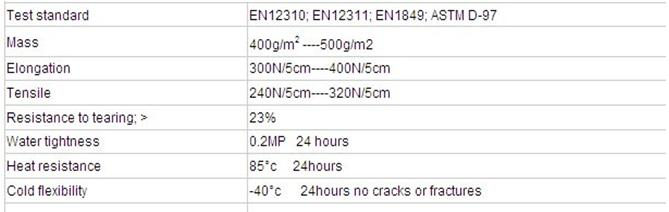

Specifications of Water and Vapor Insulation Membranes:

Water and Vapor Insulation Membranes consist of a microporous water resistant fim, sandwiched between two layees of shrink resistant spunbonded polylefin. In Roof Applications-Intended for use as a alternative to conventional kraft paper roof underlay, which are fixed over timber or steel framed roofs and to assist in the moisture management of roof cladding systems.

No addition risk of condensation, no requirements for eave and ridge venting, a warmer roof space, increased efficiency of insulation, easy installation, easier site supervision and simpler specifications.

Features of Water and Vapor Insulation Membranes:

- Q: The cushion is usually in the housing which parts

- First of all, the foundation refers to the basis of the ground below, the cushion is generally below the base, the base should be there, if the sewage treatment station, then you look at the sewage pool, the bottom of the pool should also have it

- Q: Foam concrete for the roof cushion generally do much bulk ah

- First help you correct it, foam concrete used in the roof should be the role of thermal insulation, not as a cushion.

- Q: When the cushion is used, the thickness of the protective layer is not less than ()

- Not on the roof: the general waterproof layer above can be used 15 ~ 25mm cement mortar protection.

- Q: Why do the basics of the cushion waterproofing

- As for the bottom of the bar thickness of the protective layer is generally 4cm, but if the basic floor of the concrete label is relatively high, the protective layer can be appropriately reduced.

- Q: The top floor made waterproof playing cushion layer of how to do

- 3. The first layer to do a flexible waterproof, try the valve Bai fat together with the full bricks that are roof-specific anti-aging waterproof coating.

- Q: The roof cushion is waterproof on the slope roof

- When the moisture generated by the ice dam into the external walls of the gap, the walls and insulation layer will become damp, which is the ideal environment for the breeding of mold.

- Q: Basement cushion waterproof

- Fourth, improve the waterproof performance: 1, Aggregate graded concrete, is the use of different aggregates of the aggregate and improve the content of cement mortar in the concrete, so that the mortar is filled between the aggregate, thus blocking the aggregate is not dense between the seepage channel , Improve water resistance; 2, plus concrete, is added in the concrete air conditioner or dense agent to improve the impermeability.

- Q: What is the difference between leveling and cushion?

- and only in the construction of the building at the bottom of the building, it is possible to use the relevant level of the cube, After the use of the underlying layer of the building, it is not exempt from the possibility of using leveling layer

- Q: Cushion, waterproof layer construction to do what information

- 3, waterproof layer: In order to prevent the rain into the roof, groundwater into the wall, basement and underground structures, indoor water into the floor and walls and other materials layer.

- Q: What is the relationship between the cushion and the ring beam?

- Ring beam is reinforced concrete. Is to increase the overall wall and overall stiffness, improve the side resistance performance, according to the earthquake or masonry specifications set. There may be in the ground wall, there may be in the underground wall.

1. Manufacturer Overview

| Location | Shangdong, China |

| Year Established | 2010 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | America; Europe; Asia |

| Company Certifications | ISO 9001; ISO 14001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qindao; Yantai |

| Export Percentage | 50% - 100% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 40000square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | |

Send your message to us

Water and Vapor Insulation Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20' CONTAINER m.t.

- Supply Capability:

- 500000 Square Meter/Square Meters per Week m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches