PE/PET Aluminum Foil Induction Seal Liner for Pesticides Bottle Sealing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

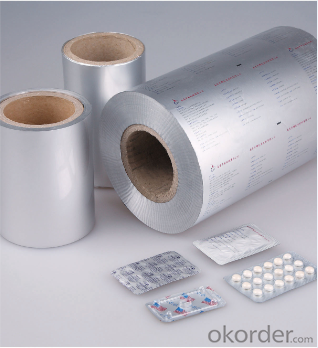

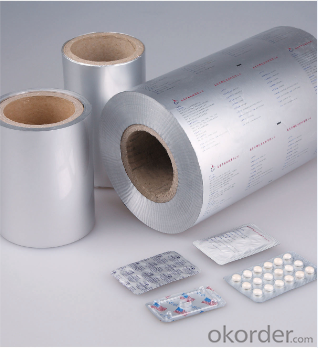

Product name: Induction seal liner for plastic and glass bottles

1. Introduction

Induction lining materials are one of the most important parts in packing industry for sealing the bottles and containers of the products for many reasons. And induction sealing is a simple and reliable method of bottle sealing. It welds an aluminum foil seal across the bottle neck.

2. Main specifications:

- Aluminum foil = 20-40 microns (0.02 - 0.03 mm)

- PE/PET/PP layer = 40-50 microns (0.04 - 0.05 mm)

- Seal backing material: pulp, foam, cardboard;

- Easy peel and non-easy peel seal available;

- Seal diameters are available from 10 mmto 180 mm;

- With different composition, liner thickness is various from 0.2mm to 1.2mm;

- It can be printed with custom logo, or embossed with any desired design;

3. Main benefits:

- Seals in freshness

- Prevent costly leaks

- Reduce the risk of tampering, pilferage, and contamination

- Extend shelf life

- Create hermetic seals

- Environment friendly

4. They can be used for sealing & packing in the different industries, including:

1- Motor, Engine, and Lubricant Oil products

2- Edible Oil products

3- Medicine products (Pharmaceutical factories for Tablet, Gel, Cream, Powders, Liquids, etc)

4- Food Products

5- Beverages, Fruit Juice, Butter, Honey, Mineral Water

6- Pesticides, Fertilizers, and Chemicals

7- Cosmetics

5. How to use:

Induction lining materials are constructed from aluminum foil membranes, coated with polymer and attached to a backing material by means of wax or polymer bond. This foil laminate is then placed inside a cap or closure, and the closure applied to the container, bringing the foil laminate into contact with mouth of the container.

The container then passes underneath the induction sealing head, where an electromagnetic field creates a low level of localized heat on the foil membrane, which is sufficient to melt both wax bond and polymer coating.

Soon after the container leaves area of the electromagnetic field, the polymer hardens, forming a flexible, yet hermetic seal between foil and neck of the container, while the backing material goes inside the cap as interior liner for more protection

6. Other information: heat induction foil liners

Name | bottle cap liner | MOQ | 100000 pieces |

Usage | This bottle cap liner is widely used in Pesticides, oil, chemical, food, medicine and other fields | Printing | 1-6 colorsprinting |

Specification | Thickness:0.1-0.3mm | ||

Shape | Round | ||

Features |

| ||

Application | bottle cap liner Is suitable for PVC,PET,PE,PP,PS ,PA,ABS ETC plastic bottles and glass bottles | ||

Min order: | 100000 pieces | ||

7. Why Choose Induction Sealing?

When properly applied, induction lined caps provide a hermetic, leak proof, and tamper evident seal. Using an induction sealing system is ideal for extending product shelf life, preserving freshness, preventing costly leaks and enhancing your product's value.

8. In order to quote you an accurate price, please kindly inform us the following information:

1.The diameter?

2.The thickness?

3.Whether printing? How many colors to be printed?

4.The material of the bottle, PE/PP/PVC/PS/GLASS or others?

5.The quantity you need?

- Q: Can aluminum sheet be used for heat exchangers?

- Yes, aluminum sheet can be used for heat exchangers. Aluminum is a commonly used material for heat exchangers due to its excellent thermal conductivity, light weight, and corrosion resistance. The high thermal conductivity of aluminum allows for efficient transfer of heat between fluids, making it suitable for various heat exchange applications. Additionally, aluminum is available in different alloys and thicknesses, providing flexibility in design and customization for specific heat exchanger requirements. Overall, aluminum sheet is a popular choice for heat exchangers in industries such as automotive, HVAC, and aerospace.

- Q: How much is one ton of aluminium plate?

- For aluminum alloy, the aluminum alloy and other metal elements, according to different metallic elements, can be divided into eight branches, 1-8 etc.. According to the contents of various metallic elements, each department can be divided into different grades of alloy, such as 8011505230031060, each kind of alloy prices are not the same. In addition, the different processing thickness, width, the process used, the cost is not the same, so the specifications are different, the price is different. As for the aluminum plate, how much is it a ton? I think you have a better answer.

- Q: What are the different surface treatments for aluminum sheets to improve corrosion resistance?

- Aluminum sheets can be treated with several methods to greatly improve their resistance to corrosion. These treatments encompass: 1. Anodizing: Widely used, anodizing involves submerging aluminum in an electrolyte solution and applying an electric current. Consequently, a protective oxide layer forms on the surface, effectively enhancing corrosion resistance. 2. Chromate Conversion Coating: Also known as chemical film or chromating, this treatment immerses aluminum in a solution with chromate compounds. This creates a thin chromate layer serving as a barrier against corrosion. 3. Powder Coating: In this dry finishing process, a powdered polymer is sprayed onto the aluminum surface and then cured under heat. The result is a durable, corrosion-resistant coating that offers exceptional protection against environmental factors. 4. E-coating: Electrophoretic coating, or e-coating, is an immersion-based process where aluminum sheets are submerged in an electrically charged paint bath. The paint particles are attracted to the surface, creating a uniform and corrosion-resistant coating. 5. Cladding: By bonding a layer of a different metal, such as stainless steel or zinc, to the surface of aluminum sheets, cladding forms a protective barrier that shields against corrosion. 6. Organic Coatings: Applying organic coatings like acrylic or polyester paints to the aluminum surface forms an effective corrosion-resistant barrier. These coatings create a protective film that prevents moisture and corrosive substances from reaching the aluminum. It's worth noting that the choice of surface treatment depends on various factors, including the specific application, environmental conditions, and desired appearance. Consulting with professionals is advisable to determine the most appropriate treatment for a particular application, as some treatments may be better suited for certain industries or environments.

- Q: This question asks for a comparison between aluminum sheets and other lightweight materials like plastic and glass, focusing on their properties and uses.

- <p>Aluminum sheets are lightweight yet strong, offering excellent strength-to-weight ratios. They are more durable and heat resistant compared to plastics, which can deform under heat and are less sturdy. Unlike glass, aluminum is less brittle and does not shatter, making it safer for certain applications. Additionally, aluminum is recyclable and has good thermal and electrical conductivity, which is not the case with plastics. However, plastics are generally cheaper and easier to shape into complex forms, while glass offers better transparency for applications requiring clear visibility. Each material has its advantages depending on the specific requirements of the application.</p>

- Q: Can aluminum sheet be used for aircraft skin panels?

- Yes, aluminum sheet can indeed be used for aircraft skin panels.

- Q: What is the typical torsional strength of aluminum sheets?

- The typical torsional strength of aluminum sheets can vary depending on various factors such as the alloy composition, thickness, and manufacturing process. However, in general, aluminum sheets have a good torsional strength compared to other materials. Aluminum alloys commonly used in sheet form, such as 6061-T6 and 5052-H32, have torsional strengths ranging from approximately 22,000 to 40,000 pounds per square inch (psi). These values represent the maximum amount of torque that can be applied to the aluminum sheet before it permanently deforms or fractures. It is important to note that torsional strength is just one aspect of the overall mechanical properties of aluminum sheets. Other factors like tensile strength, yield strength, and elongation also play significant roles in determining the suitability of aluminum sheets for specific applications. Therefore, when selecting aluminum sheets for a particular torsional application, it is essential to consider the specific requirements and consult with material suppliers or engineers to ensure the chosen aluminum sheet meets the desired torsional strength requirements.

- Q: What are the different types of surface treatments available for marine-grade aluminum sheets?

- There are several different types of surface treatments available for marine-grade aluminum sheets, each offering unique benefits and characteristics suited for various applications. 1. Anodizing: This process involves creating a protective oxide layer on the surface of the aluminum sheet through electrolysis. Anodized aluminum sheets offer excellent corrosion resistance, improved durability, and can be colored or dyed to enhance aesthetics. 2. Powder Coating: Powder coating involves applying a dry powder onto the aluminum sheet, which is then cured through heat to create a tough and durable coating. Powder-coated aluminum sheets provide excellent resistance to corrosion, abrasion, and fading, while also offering a wide range of color options. 3. Polishing: Polishing removes any imperfections on the surface of the aluminum sheet, resulting in a smooth and shiny finish. This surface treatment is often used for decorative purposes, enhancing the visual appeal of marine-grade aluminum sheets. 4. Brushing: Brushing involves creating a textured surface on the aluminum sheet using abrasive pads or brushes. This treatment is commonly used to hide scratches or imperfections and can provide a unique aesthetic appearance. 5. Chemical Conversion Coating: This treatment involves applying a chemical solution onto the aluminum sheet, which reacts with the surface to form a protective coating. Chemical conversion coatings enhance the corrosion resistance of the aluminum and can also serve as a base for further surface treatments, such as painting. 6. Clear Coating: Clear coating involves applying a transparent protective layer onto the aluminum sheet. This treatment helps to prevent corrosion and oxidation, while also maintaining the natural appearance of the aluminum surface. It is important to consider the specific requirements and intended use of the marine-grade aluminum sheets when choosing a surface treatment. Each type of treatment offers different characteristics in terms of corrosion resistance, durability, aesthetics, and cost, allowing for customization based on the specific needs of the application.

- Q: Over 5 billion aluminum cans are recycled each year. If laid end to end, these cans would form a line reaching from?

- IDK, but this may give you some idea of 1 billion. 1 Billion seconds ago.. It was 1959 1 Billion minutes ago... Christ was alive.

- Q: Can aluminum sheet be used for architectural façade systems?

- Yes, aluminum sheet can be used for architectural façade systems. Aluminum is a versatile material that offers durability, lightweight properties, and ease of installation, making it suitable for constructing attractive and functional façades in various architectural designs.

- Q: Are 101 aluminum sheets suitable for medical equipment?

- Yes, 101 aluminum sheets are suitable for medical equipment.

Send your message to us

PE/PET Aluminum Foil Induction Seal Liner for Pesticides Bottle Sealing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords