Hy Stik Packaging Tape - PE Foam Tape, Packing Tape, BOPP Tape, Aluminum Foil Tape, and Industry Tape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 500000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Double Sided EVA Foam Tape

1. Structure of Foam Tape Description

Auto trim attachment, signs, stoplights assembly, furniture industry. Our primary mission is to ensure customer satisfaction with products and services that have a high intrinsic value.

2. Main Features of the Foam Tape Tape

Building on our many years of experience in the adhesive tape field, we will continue to focus on user needs and, bearing in mind our three key words of simplicity, speed, and openness, work to ensure that every customer is fully satisfied.

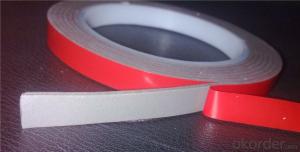

3. Double Sided EVA Foam Tape Images

4. TYPICAL PHYSICAL PROPERTIES:

CONSTRUCTION:

Backing: White/Black PE Foam

Adhesive: Solvent based acrylic adhesive

Liner: Red/Green/Blue PE liner; White release paper

TYPICAL PHYSICAL PROPERTIES:

Total Thickness (adhesives + backing): 1 mm

Density: 96kg/m3

180° Peel Adhesion: more than 1.0 kg/25mm

Holding power (hrs): not less than 100

Temperature resistance: -20~+100C

Elongation: 300%

Sizes:

Jumbo Roll: 1.00 x 300m

Cut Roll: As per customer’s requirements

Part No. | Carrier | Adhesive | Total Thickness |

DSE-08YM | EVA Foam | Hot melt rubber adhesive. | 0.8 mm |

DSE-10YM | EVA Foam | Hot melt rubber adhesive. | 1 mm |

DSE-15YM | EVA Foam | Hot melt rubber adhesive. | 1 .5 mm |

DSE-20YM | EVA Foam | Hot melt rubber adhesive. | 2 mm |

DSE-30YM | EVA Foam | Hot melt rubber adhesive | 3 mm |

DSP-08YM | White/Black PE Foam | Solvent based acrylic adhesive | 0.8 mm |

DSP-10M | PE Foam | Hot melt rubber adhesive | 1 mm |

DSP-10YM | White/Black PE Foam | Solvent based acrylic adhesive | 1 mm |

DSP-15YM | White/Black PE Foam | Solvent based acrylic adhesive | 1.5 mm |

DSP-20YM | White/Black PE Foam | Acrylic adhesive. | 2.0 mm |

DSP-30YM | White/Black PE Foam | Acrylic adhesive | 3.0 mm |

DSPH-10 | White/Black PE Foam | Synthetic rubber | 1 mm |

5.Advantage To Recommend:

We supply a wide range of products, which include double sided adhesive tape, masking tape, kraft tape, cloth tape, BOPP tape and so on.

Our biggest item is double side tape. Our double-sided adhesive tapes are with the carriers of tissue, PET, OPP, cloth, PE foam and EVA foam. And the adhesives involved are water based, solvent based and hot-melt acrylic adhesive.

According to different temperature resistances, we have two categories of masking tapes separately for general purpose and high temperature from 100°C to 160°C.

We also produce kraft tape, cloth tape and BOPP tape.

We have as our principle “Clients’ need comes first”. So we have a good variety of technical properties and sizes to meet with your different needs.

Our products enjoy popularity in markets because they have super quality with competitive price and good service.

Adhero is your ideal choice for excellent adhesive tapes and solutions.

6. FAQ:

1)What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

2)What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

3)How many carriers does your double sided adhesive tapes have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

4)Can Adhero accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

5)What are the international commodity codes for these products?

HS Code: 48231900.

6)Are you offering only jumbos rolls or slit rolls as well?

We offer Jumbos, logs, and slit rolls. All different sizes are available.

7)What are the temperatures resistances of your masking tape?

we have two general kinds of masking tapes separately for general purpose 60°C and high temperature 100°C to 160°C.

8)Are you a manufacturer or just a trader?

We are a professional manufacturer.

9)How about the quality?

The quality is very good. We have large and advanced product line.welcome to visit our company.

- Q: Is packaging tape suitable for sealing heavy boxes?

- Indeed, packaging tape proves to be fitting when it comes to securing hefty boxes. Specifically engineered to offer a robust and reliable seal, packaging tape caters to boxes of varying sizes and weights. Crafted from resilient substances like polypropylene or reinforced paper, it enhances the tape's durability and guarantees its ability to withstand the weight and pressure exerted by bulky boxes. Furthermore, packaging tape commonly possesses a potent adhesive that adheres effectively to cardboard surfaces, ensuring a tight seal capable of enduring the challenges of transportation and handling. Nevertheless, it is advisable to utilize multiple strips of tape to fortify the seal on heavy boxes, thereby enhancing their security.

- Q: Can packaging tape be used for other purposes besides packaging?

- Yes, packaging tape can be used for other purposes besides packaging. It can be used for sealing envelopes, securing loose items, repairing torn paper or books, creating temporary labels, organizing cables, and many other miscellaneous tasks.

- Q: Can packaging tape be used for sealing plastic toolboxes?

- Yes, packaging tape can be used for sealing plastic toolboxes. Packaging tape is designed to securely seal boxes and packages, and it can be used on various materials, including plastic. It provides a strong and durable seal that can withstand normal handling and transportation. However, for long-term storage or heavy-duty use, it is recommended to use a stronger and more specialized tape, such as duct tape or strapping tape, as they offer better durability and adhesion.

- Q: Can packaging tape be used for sealing packages with jewelry or valuables?

- Yes, packaging tape can be used for sealing packages containing jewelry or valuables. It provides a secure and reliable seal, ensuring that the contents of the package are protected during transit.

- Q: Can packaging tape be used for sealing plastic containers?

- Yes, packaging tape can be used for sealing plastic containers. Packaging tape is designed to adhere to various surfaces, including plastic, and provides a secure seal to prevent the contents of the container from spilling or getting damaged. It is commonly used for sealing boxes during shipping or storage, but it can also be used effectively on plastic containers. However, it is important to ensure that the tape is firmly applied and that all edges and seams are properly sealed to maintain the integrity of the container.

- Q: Can packaging tape be used for sealing plastic bags?

- Indeed, sealing plastic bags can be accomplished with the utilization of packaging tape. Designed with robust adhesive properties, packaging tape can effectively secure various items, including plastic bags. To achieve a secure seal and prevent spillage or exposure to air and moisture, the tape can be applied either along the opening or across the entire width of the bag. It is worth mentioning, though, that while packaging tape can serve the purpose, it may not be as efficient as specialized plastic bag sealing techniques like heat sealing or ziplock closures, which are specifically engineered for this particular task.

- Q: Is packaging tape safe to use on photographs?

- No, packaging tape is not safe to use on photographs as it can leave adhesive residue, damage the surface, or cause discoloration over time. It is recommended to use archival-quality photo-safe tapes or alternative methods for preserving and protecting photographs.

- Q: Selection of tapes

- For colored tapes, how to distinguish between good and bad? For the colored adhesive tape, it is usually yellow and khaki. Will be sticky, pinched, and then quickly opened, you can pull one side of the adhesive off, you can see the purity and transparency of the original film. You can also look at the thickness of the glue. If no glue is pulled or pulled apart, there's a lot of impurities in it, and the glue has no cohesion. Two is too much moisture, has been volatile, at this time, the tape has already dropped a lot of adhesive force, feel can distinguish. In fact, there are many ways to distinguish between good and bad tape, as long as the life of more attention, you can distinguish between good and bad adhesive tape.

- Q: Can packaging tape be used for sealing wooden crates?

- Sealing wooden crates can indeed be accomplished with packaging tape, which creates a sturdy and reliable bond. This ensures that the crate remains tightly sealed throughout transportation or storage. Packaging tape is specifically designed to adhere well to different surfaces, including wood, making it an excellent option for sealing wooden crates. Nevertheless, it's crucial to take into account the weight and dimensions of the crate before solely depending on packaging tape. In the case of heavier or larger crates, reinforcing the seal with supplementary methods like nails or screws may be necessary.

- Q: What are the tapes for packing tape?

- Size, core, stationery, glue, wet water, leather tape, double sided tape series

Send your message to us

Hy Stik Packaging Tape - PE Foam Tape, Packing Tape, BOPP Tape, Aluminum Foil Tape, and Industry Tape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 500000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords