Packaging Tape Singapore - BOPP Tape, Aluminum Foil Tape, Industry Tape, 3M Packing Tape

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of BOPP Tape Description

Widely used for cartom sealing and packing,light duty packing, bounding, holding and other office and household use.

2. Main Features of the BOPP Tape

Carton sealing & packing, Light duty packaging, bundling, holding, and other office & household use.

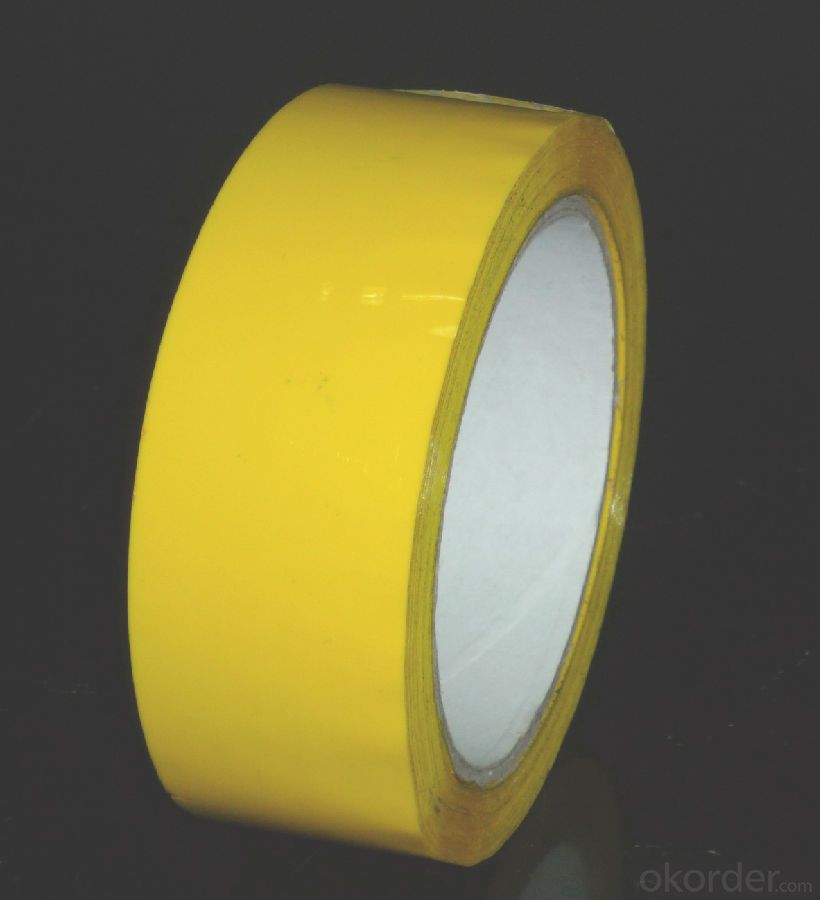

3. BOPP Tape Images

4. TYPICAL PHYSICAL PROPERTIES:

CONSTRUCTION:

Carrier: BOPP film

Adhesive: Water based acrylic adhesive.

TYPICAL PHYSICAL PROPERTIES:

Total Thickness (adhesives + carrier): 42 ± 1 um

Adhesive thickness:20 ± 1 um

Initial Tack: ³ 23#

180O Peel Adhesion (to steel): ³ 6.52 N /25mm

Holding Power: ³ 31 hrs

Item No. | Carrier | Adhesive | Total | Initial | Peel Adhesion | Elongation |

BP-40 | BOPP film | water based acrylic | 40 micron | >18# | 0.5kgf/25mm | <180%< span=""> |

BP-45 | BOPP film | water based acrylic | 45 micron | >18# | 0.5kgf/25mm | <180%< span=""> |

BP-50 | BOPP film | water based acrylic | 50 micron | >20# | 0.5kgf/25mm | <180%< span=""> |

BP-65 | BOPP film | water based acrylic | 65 micron | >24# | 7.88N/25mm | <180%< span=""> |

5.Advantage To Recommend:

We supply a wide range of products, which include double sided adhesive tape, masking tape, kraft tape, cloth tape, BOPP tape and so on.

Our biggest item is double side tape. Our double-sided adhesive tapes are with the carriers of tissue, PET, OPP, cloth, PE foam and EVA foam. And the adhesives involved are water based, solvent based and hot-melt acrylic adhesive.

According to different temperature resistances, we have two categories of masking tapes separately for general purpose and high temperature from 100°C to 160°C.

We also produce kraft tape, cloth tape and BOPP tape.

We have as our principle “Clients’ need comes first”. So we have a good variety of technical properties and sizes to meet with your different needs.

Our products enjoy popularity in markets because they have super quality with competitive price and good service.

Adhero is your ideal choice for excellent adhesive tapes and solutions.

6. FAQ:

1)What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

2)What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

3)How many carriers does your double sided adhesive tapes have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

4)Can Adhero accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

5)What are the international commodity codes for these products?

HS Code: 48231900.

6)Are you offering only jumbos rolls or slit rolls as well?

We offer Jumbos, logs, and slit rolls. All different sizes are available.

7)What are the temperatures resistances of your masking tape?

we have two general kinds of masking tapes separately for general purpose 60°C and high temperature 100°C to 160°C.

8)Are you a manufacturer or just a trader?

We are a professional manufacturer.

9)How about the quality?

The quality is very good. We have large and advanced product line.welcome to visit our company.

- Q: Are there any regulations or standards for packaging tape?

- Packaging tape is subject to regulations and standards in various countries, like the United States and European Union, to guarantee its safety and effectiveness in securing packages. These regulations encompass material composition, adhesive properties, thickness, tensile strength, and overall durability. Their purpose is to ensure that packaging tape meets specific quality and performance criteria, enabling it to withstand the challenges of transportation and handling without compromising the package's integrity. Furthermore, certain industries may have additional requirements for packaging tape, such as temperature resistance or tamper-evident features. Consequently, manufacturers and users of packaging tape must be aware of and comply with these regulations and standards to ensure the proper functioning and safety of their packaging materials.

- Q: What are the considerations for using packaging tape on delicate surfaces?

- When using packaging tape on delicate surfaces, there are several considerations to keep in mind. Firstly, it is important to choose the right type of tape. Opt for a tape specifically designed for delicate surfaces, such as low-tack or painter's tape. These tapes are typically less sticky and have a gentler adhesive that won't damage or leave residue on sensitive materials like paper, fabric, or painted surfaces. Secondly, before applying the tape, ensure that the surface is clean and free from any dust, dirt, or moisture. This will prevent any particles or contaminants from getting trapped under the tape and potentially causing damage. When applying the tape, be cautious and gentle. Avoid pressing down too hard or stretching the tape excessively, as this can increase the risk of tearing or damaging the delicate surface. Take your time and carefully smooth out any wrinkles or air bubbles to ensure proper adhesion. Additionally, it is advisable to test the tape on a small, inconspicuous area of the delicate surface before fully committing to using it. This will help you assess its compatibility and whether it causes any adverse effects or damage. Lastly, when removing the tape, do so slowly and carefully. Pull the tape back at a low angle, parallel to the surface, to minimize the risk of tearing or leaving any residue behind. If any residue does remain, use a gentle adhesive remover or warm soapy water to clean the surface. By considering these factors, you can effectively use packaging tape on delicate surfaces without causing any harm or leaving unwanted marks or residue.

- Q: Can packaging tape be used for sealing metal containers or boxes?

- Packaging tape is ideal for sealing metal containers or boxes due to its strong adhesive properties. This type of tape is specially manufactured to adhere effectively to various surfaces, including metal. By using packaging tape, you can ensure a secure and reliable seal, providing protection for the contents of the metal container or box during storage or transportation, and preventing any unwanted opening or damage. Nevertheless, it is crucial to guarantee that the surface of the metal container or box is clean and free from grease or dirt to achieve optimal adhesion. Moreover, in cases where the metal container or box will be exposed to extreme temperatures or harsh conditions, it is recommended to employ a tape specifically designed for those environments to ensure a more long-lasting seal.

- Q: Does packaging tape come in different widths for different applications?

- Yes, packaging tape does come in different widths for different applications. Packaging tape is available in various widths ranging from as small as 0.75 inches to as wide as 3 inches or even more. The choice of width depends on the specific application and the size of the package being sealed. Smaller widths are often used for lighter weight packages or for sealing small boxes or envelopes. On the other hand, wider widths are commonly used for heavy-duty or larger boxes that require extra strength and security. The availability of different widths allows users to select the most appropriate tape size based on their specific packaging needs.

- Q: Is packaging tape resistant to chemicals or solvents?

- Yes, packaging tape is generally resistant to chemicals or solvents. Most packaging tapes are made from materials such as polypropylene or polyvinyl chloride (PVC) which have good chemical resistance properties. These materials are designed to withstand exposure to a wide range of chemicals and solvents commonly encountered in industrial or commercial environments. However, it is important to note that the specific resistance of packaging tape can vary depending on the brand, type, and quality of the tape. Therefore, it is always recommended to check the product specifications or consult the manufacturer for detailed information on the chemical resistance of a specific tape.

- Q: Does packaging tape come in different colors?

- Yes, packaging tape does come in different colors. While the most common color for packaging tape is clear, there are also a variety of colors available to meet different needs and preferences. Some examples of colored packaging tape include red, blue, green, yellow, and black. These colored tapes can be used for various purposes such as color-coding different packages, indicating priority shipments, or simply adding a pop of color to your packaging. Additionally, colored packaging tape can also be used for decorative or artistic purposes, making it a versatile option for both practical and creative applications.

- Q: Does packaging tape have an expiration date?

- Packaging tape generally lacks an expiration date due to its composition of robust materials like polypropylene or PVC. These substances possess a lengthy shelf life and resist degradation over time. As long as the tape is stored in a cool, dry location, shielded from sunlight and extreme temperatures, it should retain its effectiveness for an extended period. Nevertheless, it is worth noting that the adhesive on packaging tape might lose its stickiness over time, particularly if exposed to heat or moisture. Consequently, although packaging tape may lack an official expiration date, it is advisable to utilize it within a reasonable timeframe to guarantee its adhesive properties remain intact.

- Q: What are the benefits of using transparent packaging tape?

- The benefits of using transparent packaging tape include clear visibility of the contents of the package, easy identification of any tampering or damage, professional appearance, and the tape's durability and strength for securing packages effectively.

- Q: Can packaging tape be used for sealing plastic toys?

- Yes, packaging tape can be used for sealing plastic toys. Packaging tape is designed to be strong and adhesive, making it ideal for securing and sealing various types of materials, including plastic. It can effectively hold together the different parts of a plastic toy and provide a secure seal, ensuring that the toy remains intact. However, it is important to note that packaging tape may not be as aesthetically pleasing as other specialized tapes designed specifically for toy packaging, such as clear tape or decorative washi tape.

- Q: Can packaging tape be used on different surfaces, such as cardboard, plastic, or metal?

- Yes, packaging tape can be used on different surfaces such as cardboard, plastic, or metal. Packaging tape is designed to provide a strong and secure seal, making it suitable for various materials. It adheres well to the rough surface of cardboard, ensuring that boxes and packages remain securely sealed during transit. Additionally, packaging tape can adhere to smooth surfaces like plastic, ensuring that items are securely packaged and protected. It can also be used on metal surfaces, providing a reliable seal for packages and boxes made of metal. Overall, packaging tape is versatile and can be used on different surfaces, making it an essential tool for packaging and shipping needs.

Send your message to us

Packaging Tape Singapore - BOPP Tape, Aluminum Foil Tape, Industry Tape, 3M Packing Tape

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords