Bulk Red Water Activated Kraft Paper Tape for Packing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- 30 Days/20' roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Feature Of Water activated Kraft Paper Tape AKT3630 For Packing

This item is reinforcing and water activating. With PE-Scrim facing laminated kraft paper tape.

PACKING Of Water activated Kraft Paper Tape AKT3630 For Packing

Core I.D.: 1.5” (38mm+/-1)

Jumbo Roll:0.915m X 2500m; 0.95m x 2500m; 80 rolls/20' without pallets

Cut Roll: As per customer's requirements; Firstly several rolls packed together with plastic bag, then certain quantities into a carton, finally be loaded into container with or without pallets.

Specification Of Water activated Kraft Paper Tape AKT3630 For Packing

| Product | Part No. | Carrier | Adhesive | Total Thickness | Initial Tack | Peel Adhesion |

| Kraft Paper Tape | KTH-120H | kraft paper | Hot melt adhesive | 120±5 micron | 14# | ≥14 N/25mm |

| Kraft Paper Tape | KT-400 | kraft paper | Natural Rubber adhesive | 140 micron | 10# | > 0.9kgf/25mm (to steel) |

| Kraft Paper Tape | KT-400A | kraft paper | Natural Rubber adhesive | 135 micron | 10# | > 1.0kgf/25mm (to steel) |

| Kraft Paper Tape | KT-400F | kraft paper | Natural Rubber adhesive | 145 micron | 10# | 12.5-11 N/25mm |

| Kraft Paper Tape | KT-400H | kraft paper | Natural Rubber adhesive | 120±5 micron | 10# | 13-11.5 N/25mm |

| Kraft Paper Tape | KT-400H1 | kraft paper | Natural Rubber adhesive | 135 micron | 12# | 13-11.5 N/25mm |

| Kraft Paper Tape | KT-410 | kraft paper | Natural Rubber adhesive | 130 micron | 13# | 14-12 N/25mm |

Application Of Water activated Kraft Paper Tape AKT3630 For Packing

Water activated adhesive type is 100% recycled and re-pulpable and improves packaging security by making packaging boxes stronger. With Delamination and reinforced feature make the tape stronger.

Colors available Of Water activated Kraft Paper Tape AKT3630 For Packing

Brown & White

We could supply OEM service such as core printing with customer's LOGO; round label with design of customers etc.

Special requirements will be satisfied after communications.

CONSTRUCTION Of Water activated Kraft Paper Tape AKT3630 For Packing

Backing: Reinforced Kraft paper

Adhesive: Vegetable glue

TYPICAL PHYSICAL PROPERTIES Of Water activated Kraft Paper Tape AKT3630 For Packing

Weight of carrier: 36±2 g/M2

Weight of adhesive: ≥30 g/M2

Total weight (reinforced carrier + adhesive): 130g/M2

Tensile strength (longitudinal direction): > 120N/25mm

Tensile strength (Horizontal direction): > 120N/25mm

Heat resistance: -19-60 0C

Weathers: Good

Jumbo roll size:0.94m x 1200m; 0.905m X 1200m

- Q: Can packaging tape be used for sealing packages with electronics or electrical components?

- Sealing packages containing electronics or electrical components with packaging tape is possible. However, it is essential to understand that not all packaging tapes are suitable for this purpose. To ensure the safety of the items, it is advised to opt for an anti-static or ESD-safe tape. These tapes are specifically crafted to shield sensitive electronic components from static electricity during transportation or handling. Using regular packaging tape lacking anti-static properties may expose the electronics to the risk of static discharge, potentially leading to damage or compromised performance. Therefore, it is crucial to carefully assess the specific requirements of the electronics being packaged and select an appropriate tape accordingly, guaranteeing their protection.

- Q: Can packaging tape be used for sealing plastic tubing?

- Yes, packaging tape can be used for sealing plastic tubing. However, it may not be the most effective or durable option. It is generally recommended to use specialized tape or fittings designed specifically for sealing plastic tubing to ensure a secure and reliable seal.

- Q: Does packaging tape come in different materials for specific applications?

- Different materials are used for specific applications when it comes to packaging tape. One type that is commonly used is polypropylene, which is a versatile material suitable for general-purpose packaging. It is strong, durable, and resistant to moisture and temperature changes, making it suitable for a wide range of uses. However, for more specialized purposes, different materials may be necessary. For example, if you need extra security or tamper-evident features, you might consider using security tape. This type of tape is often made of thicker and stronger materials like polyester or reinforced paper. It is designed to leave a visible mark or message when tampered with. In certain situations, packaging tape specifically designed for extreme temperature conditions may be required. For instance, if you are shipping goods that will be exposed to freezing temperatures, you will need to use freezer-grade packaging tape that remains adhesive and effective in low temperatures. Similarly, some applications may call for tape that can adhere to challenging surfaces like corrugated cardboard or recycled materials. In such cases, you can choose packaging tape with aggressive adhesive properties or one that is specifically formulated for adhesion on difficult surfaces. Moreover, there are eco-friendly options available for those who prioritize sustainability. Environmentally friendly packaging tapes are often made from renewable or recycled materials and use non-toxic adhesives. In conclusion, the choice of packaging tape material depends on the specific requirements of the application, such as security, temperature resistance, surface compatibility, or environmental concerns. It is essential to select the appropriate tape to ensure the safe and secure packaging of your items.

- Q: Can packaging tape be used for sealing metal containers or boxes?

- Yes, packaging tape can be used for sealing metal containers or boxes as it provides a strong adhesive bond and can effectively secure the contents inside. However, for heavy-duty or industrial applications, it is recommended to use specialized tapes designed specifically for sealing metal surfaces.

- Q: Can packaging tape be used for sealing pet supplies or accessories?

- Yes, packaging tape can be used for sealing pet supplies or accessories. It provides a strong and secure seal, ensuring that the items are protected and contained during transportation or storage.

- Q: Is packaging tape safe to use on painted furniture?

- Yes, packaging tape is generally safe to use on painted furniture. However, it is important to consider a few factors before using it. Firstly, ensure that the paint on the furniture is fully cured or dried, as using tape on fresh paint may cause it to peel off. Additionally, check the type of paint used on the furniture, as some types may be more prone to damage or discoloration from adhesive tape. To be on the safe side, you can test the tape on a small inconspicuous area of the furniture first to see if any damage occurs. It is also recommended to remove the tape carefully and slowly to minimize the risk of any damage.

- Q: Can packaging tape be used for sealing wooden furniture?

- Indeed, wooden furniture can indeed be sealed with packaging tape. Although it may not be the most traditional or visually appealing choice, packaging tape can effectively close off any gaps or cracks in the furniture, thus preventing the infiltration of dust, moisture, or insects. It should be noted, however, that packaging tape is not a permanent solution, as it may not offer the same level of durability or stability as sealing methods explicitly crafted for wooden furniture, such as wood glue or epoxy. Consequently, it is advisable to employ packaging tape as a temporary remedy until a more suitable sealing technique can be implemented.

- Q: Can packaging tape be used for sealing packages with breakable items like ceramics?

- Yes, packaging tape can be used for sealing packages with breakable items like ceramics. However, it is recommended to use additional protective measures such as bubble wrap or foam padding to ensure the safe transportation of fragile items.

- Q: What is the average width of packaging tape?

- The average width of packaging tape is typically 2 inches.

- Q: Can packaging tape be used for securing pallet loads?

- Yes, packaging tape can be used for securing pallet loads. Packaging tape is commonly used to secure boxes and packages, but it can also be used to reinforce and secure pallet loads. It helps to hold the items on the pallet together, preventing them from shifting or falling off during transportation or storage. However, it's important to note that the effectiveness of packaging tape for securing pallet loads may depend on the weight and stability of the items being transported. In some cases, additional strapping or banding may be needed for extra security.

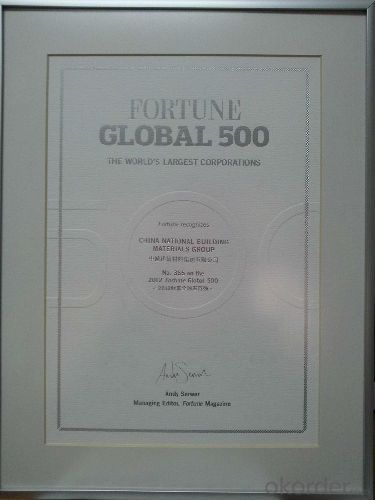

1. Manufacturer Overview

| Location | Fujian, China |

| Year Established | 1994 |

| Annual Output Value | Above US$ 1000 Million |

| Main Markets | Southeast Asia; South America; Eastern Europe; North America; Northern Europe; South Asia; Western Europe; Africa; Mid East |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 101-200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | produce single sided tapes,double sided tapes, masking tape, Opp tape |

| Product Price Range | Low; Average |

Send your message to us

Bulk Red Water Activated Kraft Paper Tape for Packing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- 30 Days/20' roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords