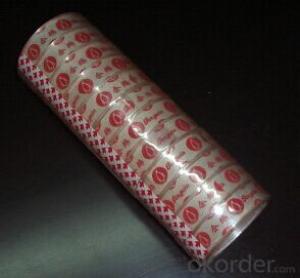

Opp Packaging Tape

Opp Packaging Tape Related Searches

Packaging Tape Package Sealing Tape Heavy Duty Packaging Tape Personalised Packing Tape Packaging Tape Art Transparent Packing Tape Bopp Bag Sealing Tape Nylon Packing Tape Shipping Tape Kraft Packaging Tape Heavy Duty Shipping Tape Protective Film Tape Heavy Duty Mounting Tape Aluminium Tape Binding Tape Automotive Masking Tape Best Shipping Tape Polypropylene Tape Tape Dispenser For Packing Tape Aluminum Tape Best Place To Buy Packing Tape Brown Paper Packing Tape Printed Box Tape Copper Tape Tape Aluminium Binding Cloth Tape Industrial Adhesive Tape Reinforced Aluminum Tape Pe Tape Removable Double Sided Mounting TapeOpp Packaging Tape Supplier & Manufacturer from China

Opp Packaging Tape is a versatile and widely used product in the packaging industry. It is known for its excellent adhesive properties and durability, making it suitable for various applications such as sealing boxes, wrapping gifts, and securing packages. This type of tape is made from polypropylene, which gives it a strong and flexible structure, ensuring that it can withstand the demands of everyday use.The Opp Packaging Tape is commonly utilized in various industries, including e-commerce, logistics, and retail, where efficient and secure packaging is crucial. Its ease of use and ability to provide a tight seal make it a popular choice among businesses and individuals alike. The tape is also appreciated for its clarity, which allows for easy identification of the contents within the package without compromising the overall aesthetic.

Okorder.com is a reputable wholesale supplier of Opp Packaging Tape, boasting a large inventory to cater to the diverse needs of customers. They offer competitive prices and reliable service, ensuring that businesses can source high-quality packaging materials at an affordable cost. By partnering with Okorder.com, customers can benefit from a consistent supply of Opp Packaging Tape, helping them to maintain smooth operations and meet their packaging requirements.

Hot Products