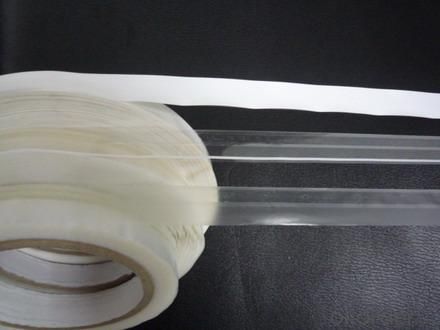

Gorilla Packaging Tape for Clear Sealing - Amazon's Choice for Bag Sealing, Carton Packing, Gift Packaging

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- 30 Days/20' roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications Of Crystal Clear Sealing Tape (Packing Tape) for Bag Sealing, Carton Packing, Gift Packaging:

Suitable for sealing plastic bags such as OPP or PP .PE materials.

Reusable, no peel off of adhesive, no residue.

It does not react chemically with the contents of the bags to color changes etc.

Name Bag Sealing Tape

Item No BG-14

Carrier PET film

Release Liner PE Film

Adhesive Acrylic Adhesive

Release Liner width 13/14mm

Carrier Width 6mm

AB Side Coating Width 4mm/6mm (left/right glue)

Stability and Reactivity Of Crystal Clear Sealing Tape (Packing Tape) for Bag Sealing, Carton Packing, Gift Packaging:

Chemical Stability: Stable and non-reactivity

Conditions to Avoid: Away from high temperature

Incompatibility with various substances:specific materials/condition to avoid.

Hazardous Decomposition Products:Thermal decomposition will produce mainly C02,and slightly CO.

Hazardous Polymerization:Can not occur

Transport Information Of Crystal Clear Sealing Tape (Packing Tape) for Bag Sealing, Carton Packing, Gift Packaging:

Not a hazardous material for DOT shipping.

UN:None

Packaging sign:According to the buyer

Packaging Category:No information found/According to the buyer.

Shipping Marks: According to the buyer

Remarks Of Crystal Clear Sealing Tape (Packing Tape) for Bag Sealing, Carton Packing, Gift Packaging:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and be kept away wet and/or heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

- Q: Can packaging tape be used for sealing packages with high-value contents?

- Yes, packaging tape can be used for sealing packages with high-value contents. However, it is important to ensure that the tape used is strong, durable, and tamper-evident to provide adequate security and protection for the valuable contents.

- Q: Does packaging tape come in different thicknesses for added durability?

- Yes, packaging tape does come in different thicknesses for added durability. The thickness of packaging tape is measured in mils, which refers to the thickness of the tape in thousandths of an inch. Common thicknesses for packaging tape range from 1.6 mils to 3.1 mils. Thicker tape is generally more durable and able to withstand heavy-duty applications. Thicker tapes are ideal for securing large or heavy packages, as they offer greater strength and tear resistance. Thinner tapes, on the other hand, may be suitable for lighter items or less demanding packaging needs. Thus, the availability of different thicknesses in packaging tape allows users to choose the most appropriate tape for their specific durability requirements.

- Q: Is packaging tape resistant to mold or mildew?

- Packaging tape is generally resistant to mold or mildew. Typically, materials like polypropylene or vinyl, which do not offer a suitable environment for mold or mildew growth, are used to make most packaging tapes. These materials are impermeable and waterproof, preventing moisture from penetrating and creating conditions favorable for mold or mildew to thrive. Moreover, packaging tape often has a mold or mildew-resistant adhesive coating. Nevertheless, it is worth mentioning that if the tape is applied to a surface already contaminated with mold or mildew, it may not hinder further growth or eradicate the existing mold or mildew.

- Q: What is the purpose of packaging tape?

- Packaging tape serves the purpose of securely sealing and reinforcing packages, boxes, or containers during storage, transportation, or shipping. Its design ensures a strong and long-lasting bond that keeps the package contents intact and protected. Furthermore, it acts as a clear indicator of tampering, allowing for easy identification of any unauthorized opening or interference. Additionally, it safeguards the package from dust, moisture, and other external elements, thereby maintaining the integrity and quality of the enclosed items. In summary, packaging tape plays a crucial role in providing a dependable and efficient solution for sealing and safeguarding packages, making it an indispensable tool for businesses, individuals, and organizations engaged in shipping and logistics.

- Q: How do I prevent packaging tape from getting tangled?

- To prevent packaging tape from getting tangled, ensure that the tape roll is placed on a dispenser or a stationary surface with the sticky side facing down. Additionally, avoid pulling the tape too quickly or at an angle, as this can cause it to twist and tangle. Taking these precautions will help maintain the tape's smooth flow and prevent any frustrating tangles.

- Q: Are there any eco-friendly options for packaging tape?

- Yes, there are eco-friendly options for packaging tape available. Some alternatives to traditional plastic packaging tape include paper tape, which is made from renewable resources and can be recycled or composted. Another option is water-activated tape, which is also made from paper and uses a natural adhesive activated by water. These eco-friendly packaging tape options help reduce plastic waste and are more sustainable choices for packaging needs.

- Q: What are the alternatives to packaging tape for sealing packages?

- Some alternatives to packaging tape for sealing packages include adhesive strips, glue sticks, twine or string, rubber bands, heat-sealing machines, and self-sealing envelopes or bags.

- Q: How do I prevent packaging tape from tearing during application?

- To prevent packaging tape from tearing during application, there are several steps you can take: 1. Choose the right type of packaging tape: Make sure you are using a high-quality packaging tape that is designed for heavy-duty applications. Look for tapes that are specifically labeled as tear-resistant or reinforced. 2. Prepare the surface: Before applying the tape, ensure that the surface is clean, dry, and free from dust or debris. A dirty or uneven surface can cause the tape to tear easily. 3. Use proper technique: When applying the tape, hold the roll at a slight angle to the surface rather than perpendicular. Applying it at an angle will reduce the amount of friction between the tape and the surface, minimizing the chances of tearing. 4. Apply gentle pressure: Apply the tape smoothly and evenly, using gentle pressure. Avoid pulling or tugging too hard, as it can strain the tape and increase the risk of tearing. 5. Avoid extreme temperatures: Extreme temperatures can affect the adhesive properties of the tape and make it more prone to tearing. If possible, store the tape in a controlled environment and avoid using it in extremely hot or cold conditions. 6. Consider using a tape dispenser: Using a tape dispenser can help you apply the tape more smoothly and evenly, reducing the chances of tearing. It also provides better control and minimizes the strain on the tape. 7. Cut the tape cleanly: When cutting the tape, use a sharp blade or scissors to ensure a clean cut. A jagged or uneven cut can weaken the tape and make it more likely to tear. By following these tips, you can significantly reduce the chances of packaging tape tearing during application and ensure a secure and reliable seal for your packages.

- Q: Is packaging tape resistant to UV rays?

- Yes, packaging tape is generally resistant to UV rays. Most packaging tapes are made from materials like polypropylene or polyethylene, which have inherent resistance to UV radiation. This means that the tape can withstand exposure to sunlight and other sources of UV rays without deteriorating or losing its adhesive properties. However, it is important to note that prolonged exposure to UV rays can still cause some degradation over time. To ensure maximum longevity, it is recommended to store and use packaging tape in a cool, dry place away from direct sunlight whenever possible.

- Q: General adhesive tape is a taste, the size of the taste depends on the formula of glue, low molecular weight content, taste will be larger, once adhesive tape, it has a very small taste tape, we have been using.

- The bubble is on the tape slitting machine when cutting the air into the tape to improve only by changing the type or sub machine will have a bubble for 1 months or longer, the bubbles will automatically eliminate, the premise is to increase the cutting of the tape tension, if loose, put a few day and bubble;

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | Southeast Asia; South America; Eastern Europe; North America; Northern Europe; South Asia; Western Europe; Africa; Mid East |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 10%-20% |

| No.of Employees in Trade Department | 11-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 600 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | produce single sided tapes,double sided tapes, masking tape, Opp tape |

| Product Price Range | High; Average |

Send your message to us

Gorilla Packaging Tape for Clear Sealing - Amazon's Choice for Bag Sealing, Carton Packing, Gift Packaging

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- 30 Days/20' roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords