Double Sided Tissue Tape White Color - China's Top Brand Scotch Packaging Tape 43.7

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

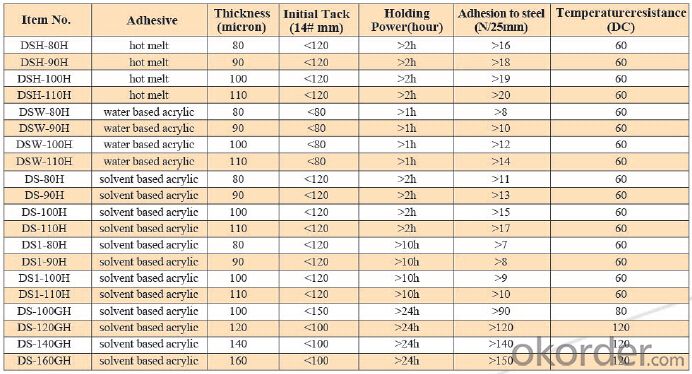

Typical Physical Reports of Double Sided Tissue Tape

Description

The Double Sided Tissue Tape is of tissue as the carrier, coating with hot melt adhesive, water based acrylic, solvent based acrylic. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

The thickness of the tape can be customized.

Application

General purpose of Double Sided Tissue Tape: widely used for bonding, fixing for leather, foam, sponge, garment, shoe, luggage, plastic, paper splicing and stationery.

Packaging & Delivery

Packaging Detail:

Log Roll: Length 1000mm; width: 1050mm, 1260mm, 1040mm..

Cut Roll: As per customer’s requirements

Delivery Detail: within 7-15 working days after receiving your deposit

Service

Sample of Double Sided Tissue Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service

Well-trained & experienced sales representative are ready to answer you.

About us

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Welcome to contact us and visit the factory!

- Q: Is packaging tape suitable for sealing heavy boxes?

- Yes, packaging tape is suitable for sealing heavy boxes. Packaging tape is designed to provide a strong and secure seal for boxes of various sizes and weights. It is made from durable materials such as polypropylene or reinforced paper, which adds strength to the tape and ensures that it can handle the weight and pressure of heavy boxes. Additionally, packaging tape usually has a strong adhesive that bonds well with cardboard surfaces, ensuring a tight seal that can withstand the rigors of transportation and handling. However, it is recommended to use multiple strips of tape to reinforce the seal on heavy boxes for added security.

- Q: Can packaging tape be used for sealing plastic folders?

- Yes, packaging tape can be used for sealing plastic folders.

- Q: Is packaging tape compatible with automatic packaging machines?

- Yes, packaging tape is compatible with automatic packaging machines. Automatic packaging machines are designed to work with a variety of packaging materials, including packaging tape. They are equipped with mechanisms to efficiently dispense and apply packaging tape to seal packages.

- Q: When the box is sealed, the tape is very noisy and very harsh. What shall I do?

- Silent tape refers to the absence of sound when peeling, which can be used to prevent static electricity

- Q: Does packaging tape come in different textures?

- Yes, packaging tape does come in different textures. While the most common type of packaging tape is smooth and glossy, there are also textured variations available. Some examples of textured packaging tape include rubberized tapes, which have a soft and grippy texture, and paper-based tapes, which have a rougher texture similar to masking tape. These textured tapes are often used for specific purposes, such as providing extra grip or adhering to difficult surfaces. However, it's important to note that textured packaging tapes may have different adhesive properties and may not be suitable for all applications.

- Q: Can packaging tape be used for sealing industrial or manufacturing goods?

- Indeed, packaging tape proves itself invaluable in the sealing of industrial or manufacturing goods. Its purpose is to secure and seal packages, boxes, and cartons, thus rendering it highly adaptable across a vast array of applications. In the manufacturing industry, among others, it is frequently employed to guarantee the safe transport and storage of goods. By establishing a robust and enduring seal, packaging tape effectively shields the contents from spillage, damage, or exposure to external elements like moisture or dust. Furthermore, it boasts effortless application and removal, thereby providing a convenient means of efficiently sealing substantial quantities of industrial or manufacturing goods.

- Q: Does packaging tape come in different thicknesses?

- Indeed, various thicknesses can be found when it comes to packaging tape. One can find packaging tape in a range of thicknesses, which caters to diverse needs and demands. Heavier-duty tasks that necessitate extra durability and resilience usually call for thicker tapes. Conversely, thinner tapes are commonly utilized for lighter parcels or regular daily applications. The decision regarding the thickness depends on factors such as the weight and dimensions of the package in question, as well as the desired level of fortification.

- Q: What is the cost of packaging tape?

- The cost of packaging tape can vary depending on factors such as brand, quantity, and quality. On average, a standard roll of packaging tape can range from $2 to $5. However, bulk packs or larger rolls may be available at a discounted price. Additionally, specialty or heavy-duty packaging tapes designed for specific purposes might be priced higher. It is recommended to compare prices from different suppliers or retailers to find the best deal that suits your packaging needs.

- Q: Can packaging tape be used for sealing plumbing or pipe fittings?

- No, packaging tape should not be used for sealing plumbing or pipe fittings. Packaging tape is not designed to withstand the pressure and conditions that plumbing systems require. It is not suitable for use with water or other liquids, and it may not provide a secure and long-lasting seal. Plumbing and pipe fittings require specific types of sealing materials, such as Teflon tape, pipe dope, or thread sealants, which are specifically designed for plumbing applications. Using packaging tape for sealing plumbing or pipe fittings can result in leaks, water damage, and potentially costly repairs. It is always recommended to use the proper sealing materials and techniques recommended by plumbing professionals.

- Q: Is packaging tape resistant to punctures or tears?

- Yes, packaging tape is generally resistant to punctures or tears. It is designed to provide durability and strength, making it effective for securing packages and protecting their contents during transit.

Send your message to us

Double Sided Tissue Tape White Color - China's Top Brand Scotch Packaging Tape 43.7

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches