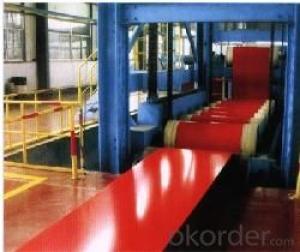

(PE)Color Coated Sheet-PPGI /Hot Dipped Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.(PE)Color Coated Sheet-PPGI Features:

. A strong anti-corrosion properties, good corrosion resistance. The use of hot dipped galvanized steel substrates for the Color Painted steel coil, with the exception of zinc have anti-corrosion layer, a layer of coatings have seized coverage and protection, allowing effective anti-rust products, galvanized coil about life than double.

. A good cold-formed molding processing, users can directly processed into finished products. Substituting wood to steel, easy to transport, and efficient construction, energy conservation.

2.Applications of (PE)Color Coated Sheet-PPGI

* Used as roof panel, wall panel in steel structure in warehouse,

factories exhibition hall container houses, cold storage

*It is also mainly used in light industry, automobile, construction,

animal husbandry, fishery and commerce, etc,

3.Product information:

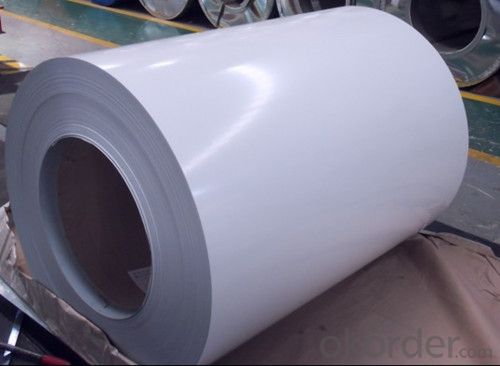

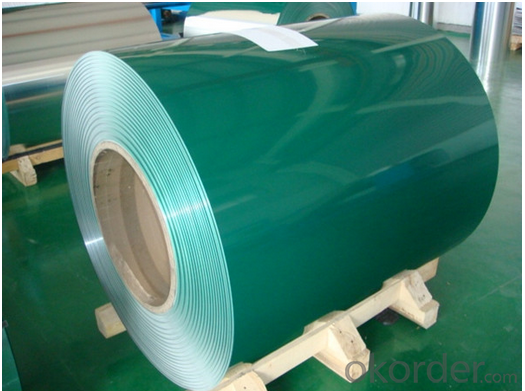

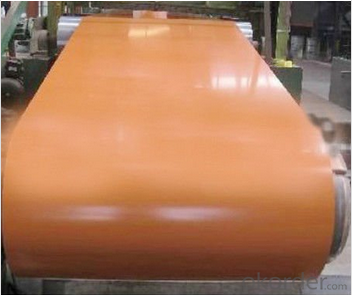

| PRODUCT | PPGI Metal Building Materials |

| STANDARD | GB/T-12754: 2006, JIS330, ASTM A653, JIS G330, GB/T2518, ASTM A792, JIS G3321, JIS G3317 |

| BASE METAL | Hot dipped Galvanized steel sheet/coil, Hot dipped Galvalume steel sheet/coil |

| EQUIPMENT | Double coating double baking; three coating three painting |

| SUPPLY CAPACITY | 500,000 Tons per Year |

| SIZE | Thickness: 0.3mm-1.0 mm,thickness tolerance: +/- 0.02mm Width : 700mm—1250mm |

| ZINC COATING | 30g/m2-150g/m2 |

| PAINT THICKNESS | Top Side: 10-25 microns; Back Side: 4-8 microns |

| COIL WGT | Normally 5 Tons per Coil, aslo as required by customer |

| COIL ID | 508mm/610mm |

| SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

4.(PE)Color Coated Sheet-PPGI image:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: How are steel coils used in the manufacturing of storage tanks?

- Steel coils are used in the manufacturing of storage tanks as they are rolled into cylindrical shapes and welded together to form the tank's body. The coils provide strength and durability to the structure, ensuring the tank can withstand the pressure and weight of stored materials.

- Q: Nickel is ferro magnetic in nature. But when it is added with stainless steel, it makes stainless steel non-magnetic. What is the structural changes happened with the presence of nickel?

- Dear Ian, Magnetism doesn't add up or average out in that manner. Ferro-magnetism requires that all the spins align. This is a complex effect and needs a subtle interaction between adjacent atoms in the lattice and their singlet electrons. The distance between the the atoms is what is important. Some stainless steels are ferromagnetic because they have the correct spacing, others are not because the spacing is wrong. This spacing is influenced by the makeup of the alloy. Hope that helps a bit:RufusCat Copyleft:RufusCat

- Q: How do steel coils compare to other materials in terms of cost?

- Steel coils are generally more cost-effective compared to other materials. Steel is a widely available and abundant material, which makes it relatively inexpensive to produce. Additionally, steel coils have a longer lifespan and require minimal maintenance, reducing overall costs in the long run. The durability and strength of steel also make it an ideal choice for various applications, further enhancing its cost-effectiveness. When compared to materials like aluminum or copper, steel coils tend to be more affordable, making them a preferred choice for many industries.

- Q: i have searched high and low, but can't find information anywhere!bainitic and pearlitic steels are too in depth, just would like to know if it is hsla steel, or mild steel, or stainless steel etc...thank you in advance :)

- Hoghead has it right, it is quite mild steel, every time they try harder steel it does not stand up to the stress and breaks more readily. Rail, odd as it seems can get corrugated and rough same as a dirt road and needs to be reground from time to time to reshape the top part of the rail. Rust is not a problem on a track in use so stainless would be a unnecessary expense. Also, in high wear places, specialized welding crews come in in add new material to the most worn parts, as in switches and then regrind it to the proper profile, mild steel accepts this much better than a harder steel would.

- Q: What are the common methods of protecting steel coils from corrosion?

- There exist various techniques commonly employed for safeguarding steel coils against corrosion. 1. Coating: To establish a barrier between the steel coil and the corrosive environment, a protective coating can be expertly applied. Multiple types of coatings, including paint, epoxy, or zinc, are available, each possessing superb corrosion resistance and obstructing the ingress of moisture and oxygen onto the steel surface. 2. Hot-dip galvanizing: Immersing the steel coil in a bath of molten zinc constitutes the hot-dip galvanizing method, resulting in the formation of a substantial zinc coating. This zinc coating acts as a sacrificial barrier, effectively shielding the steel against corrosion. Hot-dip galvanizing is especially advantageous in harsh environments or when prolonged exposure to the outdoors is anticipated. 3. VCI (Volatile Corrosion Inhibitor) packaging: VCI packaging entails encasing the steel coils in specially designed film or paper laced with volatile corrosion inhibitors. These inhibitors vaporize and form a protective layer on the steel surface, effectively preventing corrosion. VCI packaging is commonly employed for short-term storage or transportation of steel coils. 4. Desiccants: Moisture plays a significant role in the corrosion process. Consequently, utilizing desiccants such as silica gel or activated alumina aids in moisture absorption and the maintenance of a dry environment surrounding the steel coils. Desiccants are often combined with other protective methods to enhance corrosion protection. 5. Appropriate handling and storage: Employing proper practices for handling and storage significantly mitigates the risk of corrosion. Steel coils should be stored in a dry environment, distanced from moisture sources. Additionally, clean gloves should be utilized during handling to prevent the transfer of corrosive contaminants. Regular inspection and maintenance of the storage area are crucial for identifying and addressing potential corrosion risks. By employing one or a combination of these methods, steel coils can be effectively preserved against corrosion, guaranteeing their longevity and structural integrity.

- Q: does anyone out there know where to get a good deal on a pedal steel guitar? i am from northern indiana and i'm willing to travel some if i have to.i am just getting into pedal steel guitar and i really don't have any idea what i need. i don't know how to play a guitar (i do know how to play the piano and the drums) at all but i want to learn to play the pedal stell guitar and i can't do that without getting one first so, if anyone can help me out i would greatly appreciate it! :o)

- I agree with everything that Lester said. Another thought is to consider starting on a lap steel guitar rather than a pedal steel - its related, a little easier to learn on, and less expensive. Once you get proficient on the lap steel, you can move up to the pedal steel. Good luck!

- Q: How do steel coils compare to other materials like aluminum or copper?

- Steel coils have several advantages and disadvantages when compared to other materials like aluminum or copper. One major advantage of steel coils is their strength and durability. Steel is known for its high tensile strength, which means it can withstand heavy loads and high stress without deformation. This makes steel coils ideal for applications that require strong and sturdy materials, such as construction, automotive manufacturing, and transportation industries. In comparison, aluminum and copper are generally softer and less strong than steel, making them less suitable for heavy-duty applications. Another advantage of steel coils is their cost-effectiveness. Steel is a relatively inexpensive material compared to aluminum or copper, making it a more affordable option for large-scale projects or mass production. Additionally, steel is highly recyclable, contributing to its cost-effectiveness and sustainability. However, steel coils also have some drawbacks compared to aluminum or copper. One notable disadvantage is their weight. Steel is significantly denser than aluminum or copper, which can make steel coils heavier and more challenging to handle and transport. This can be a drawback in industries where weight is a critical factor, such as aerospace or electrical applications. Another disadvantage of steel coils is their susceptibility to corrosion. While aluminum and copper are naturally corrosion-resistant, steel is prone to rust and oxidation. Therefore, steel coils need to be properly protected and coated to prevent corrosion, which adds to the overall cost and maintenance requirements. In summary, steel coils offer superior strength, durability, and cost-effectiveness compared to aluminum or copper. However, they are generally heavier and more prone to corrosion. Ultimately, the choice between steel, aluminum, or copper will depend on the specific application, budget, and requirements of the project.

- Q: Can steel coils be coated with RFID technology?

- Yes, steel coils can be coated with RFID (Radio Frequency Identification) technology. The RFID tags can be securely attached to the surface of the steel coils, allowing for efficient tracking, identification, and monitoring throughout the supply chain process.

- Q: What is the standard thickness of steel coils?

- The standard thickness of steel coils can vary depending on the specific application and industry requirements. However, in general, steel coils are typically available in a range of thicknesses between 0.5mm to 10mm. The desired thickness of a steel coil is determined by factors such as the intended use, structural requirements, and manufacturing processes. Thicker steel coils are often used for heavy-duty applications that require greater strength and durability, while thinner coils are suitable for lighter applications where flexibility and weight reduction are important. It is important to consult industry standards and specific project requirements to determine the appropriate thickness for steel coils in any given application.

Send your message to us

(PE)Color Coated Sheet-PPGI /Hot Dipped Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords