5083 Aluminum Coil Price - PE Coated Aluminum Coils for Decoration Blue AA3003

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

PE Coated aluminium coils are widly used in decoration field.For example, it can used in ceiling, wall curtain ect. For the painting kinds, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much cheaper than PVDF.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

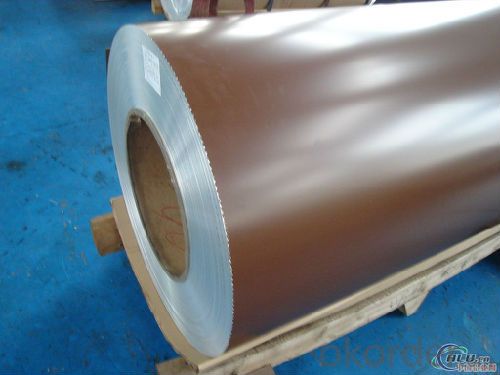

3. Image

4.Products Specifcation

| Alloy | Temper | Color | Coil ID | Coated Thickness |

| AA3003 | H14 | PE Blue | 505mm | 22-25 microns |

5. FAQ

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Are aluminum coils suitable for interior design applications?

- Yes, aluminum coils are suitable for interior design applications. Aluminum is a versatile material that offers a wide range of benefits for interior design projects. Firstly, aluminum is lightweight, making it easy to handle and install. This is especially advantageous for projects that require large-scale installations or suspended ceilings. Additionally, aluminum coils are highly durable and resistant to corrosion, ensuring their longevity and making them suitable for high-traffic areas. Furthermore, aluminum can be easily customized and shaped to meet specific design requirements, allowing for endless design possibilities. The material is also available in a variety of finishes, such as brushed, polished, or anodized, which can enhance the aesthetic appeal of any interior space. Moreover, aluminum is a sustainable and eco-friendly option, as it is easily recyclable and has a low carbon footprint compared to other materials. Overall, aluminum coils are a practical and aesthetically pleasing choice for interior design applications.

- Q: How are aluminum coils used in the production of transportation vehicles?

- Aluminum coils play a vital role in manufacturing transportation vehicles, especially cars and planes. These coils are typically made from high-quality aluminum alloys because they are lightweight, strong, and resistant to corrosion. In the automobile industry, aluminum coils are primarily used to build vehicle bodies, including the frame, doors, hoods, and trunk lids. The lightweight nature of aluminum helps reduce fuel consumption and improve energy efficiency. This makes it a preferred choice for vehicle manufacturers who want to meet environmental regulations and improve fuel economy. Aircraft manufacturing also relies on aluminum coils to reduce weight and ensure optimal flight performance. By incorporating aluminum coils into key components like fuselages, wings, and engine parts, aircraft manufacturers can save a significant amount of weight without compromising structural integrity and durability. The use of aluminum coils in transportation vehicles also contributes to improved safety standards. Aluminum's ability to absorb crash energy makes it an ideal material for manufacturing impact-absorbing structures, such as bumpers and crash boxes in cars. This provides enhanced protection for passengers during collisions. Furthermore, aluminum coils have excellent heat dissipation properties, reducing the risk of engine and other critical system overheating. This is particularly beneficial for high-performance vehicles, where efficient cooling is essential for maintaining optimal operating conditions. In conclusion, aluminum coils are extensively used in the production of transportation vehicles due to their lightweight, strong, corrosion-resistant, and thermally conductive properties. By incorporating aluminum coils into vehicle manufacturing, the automobile and aircraft industries can achieve weight reduction, improved fuel efficiency, enhanced safety, and superior performance. This allows them to meet evolving market demands and sustainability goals.

- Q: What is an aluminum coil and what is it used for?

- An aluminum coil is a long, thin, and flat strip of aluminum that is typically rolled up. It is used in various industries, including construction, automotive, and electrical, due to its excellent properties such as lightweight, corrosion resistance, and conductivity. Aluminum coils are commonly used for manufacturing various products like roofing, gutters, cans, heat exchangers, and electrical wiring, among others.

- Q: How are aluminum coils joined in a continuous process?

- Various techniques, including welding, brazing, and adhesive bonding, are utilized in the continuous process of joining aluminum coils. Joining aluminum coils through welding is a widespread method. It involves melting the coil edges and subsequently merging them. This can be accomplished through different welding processes, such as TIG welding, MIG welding, or laser welding. These welding methods establish a sturdy and long-lasting bond between the coils. Brazing is an alternative technique employed for joining aluminum coils. It entails heating the coils and utilizing a filler material with a lower melting point than aluminum to create the joint. The filler material, typically a brazing alloy, is applied to the joint area. Upon heating, it liquefies and flows into the gap between the coils, creating a solid bond as it cools. Adhesive bonding is also employed during the continuous joining of aluminum coils. This approach involves applying a specialized adhesive or glue to the coil surfaces that require joining. The adhesive is chosen meticulously for its exceptional bonding properties with aluminum. The coils are then pressed together, and the adhesive undergoes curing, resulting in a robust and dependable bond. Each joining technique possesses distinct advantages and is selected based on factors such as application requirements, the aluminum type used, and the desired level of strength and durability. The choice of joining method in a continuous process relies on the specific demands of the production line and the final product.

- Q: Are there any limitations to using aluminum coils?

- Yes, there are several limitations to using aluminum coils. Firstly, aluminum coils are more expensive compared to other coil materials such as copper. This can be a limiting factor for individuals or businesses with budget constraints. Secondly, aluminum coils have lower thermal conductivity than copper coils. This means that they are less efficient at transferring heat, which can result in decreased performance in some applications. Additionally, aluminum is more susceptible to corrosion and oxidation compared to other materials. This can be a limitation in environments that are highly corrosive, such as coastal areas or industrial settings. Furthermore, aluminum coils are generally not suitable for high-pressure applications. They are more prone to leaks or failures under high pressure, which can limit their use in certain HVAC systems or refrigeration units. Lastly, aluminum coils are not as malleable as copper coils, making them more difficult to work with during installation or repair. This can lead to increased labor costs or potential damage to the coils during handling. Overall, while aluminum coils have their advantages such as being lightweight and environmentally friendly, they also have limitations that need to be considered based on the specific application and requirements.

- Q: Can aluminum coils be used in electrical wiring applications?

- Yes, aluminum coils can be used in electrical wiring applications. Aluminum is a commonly used material in electrical wiring due to its excellent conductivity and cost-effectiveness. However, proper installation techniques and precautions are necessary to prevent potential issues such as corrosion and overheating.

- Q: Can aluminum coils be used for heat sinks?

- Yes, aluminum coils can be used for heat sinks.

- Q: Can aluminum coils be formed into different shapes?

- Yes, aluminum coils can be formed into different shapes. Aluminum is a highly malleable metal, which means it can easily be bent, shaped, and formed without breaking. This property makes it an ideal material for various applications where flexibility and versatility are required. Aluminum coils can be formed into different shapes using a variety of techniques, such as bending, rolling, stamping, extrusion, or even by using specialized machinery like a coil forming machine. These processes allow the aluminum coils to be transformed into a wide range of shapes, including sheets, plates, tubes, wires, or complex three-dimensional forms. The ability to form aluminum coils into different shapes makes it an excellent choice for industries such as construction, automotive, aerospace, and manufacturing, where customized parts and components are often needed.

- Q: Describe the process of rolling aluminum coil in a few sentences.

- <p>The process of rolling aluminum coil involves several key steps. Initially, aluminum ingots are heated to a specific temperature to make them pliable. Then, they are passed through a series of rolling mills where the ingots are pressed and shaped into thin sheets or coils. This process reduces the thickness and increases the length and width of the material. During rolling, the aluminum may be annealed to improve its ductility and strength. After rolling, the aluminum coil is cooled, cleaned, and inspected for quality. The final step includes coiling the rolled aluminum into manageable rolls for storage and transportation. This process is critical for producing aluminum coils used in various industries such as construction, automotive, and packaging.</p>

- Q: What is the typical modulus of elasticity for aluminum coils?

- The typical modulus of elasticity for aluminum coils is around 70 GPa (gigapascals).

Send your message to us

5083 Aluminum Coil Price - PE Coated Aluminum Coils for Decoration Blue AA3003

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords