G8 Aluminum Coil - PE Color Coated Aluminium Coils for Decoration AA3003

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

PE Coated aluminium coils are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. However, the price of PE Colored aluminium coils is much more competitive than PVDF aluminium coils. So many customers prefer PE coated aluminium coils.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

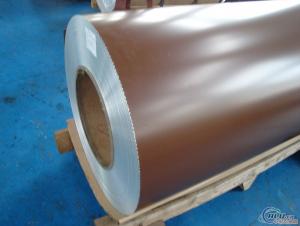

3.Image

4. Products Specification

| Alloy | Painting | Color Series | Coating Thickness | Coil Weight |

| AA3003 | PE | RAL | 22-25 MICRONS | About 2.5 tons |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 8 tons.

- Q: Can aluminum coils be used in roofing applications?

- Yes, aluminum coils can be used in roofing applications. Aluminum is a popular choice for roofing due to its lightweight nature, corrosion resistance, and durability. Aluminum coils are commonly used in the construction of roofing systems, including standing seam roofs, metal shingles, and flat roofs. The coils are typically formed into panels or sheets that are installed on the roof, providing protection against weather elements and enhancing the aesthetic appeal of the building. Additionally, aluminum's reflective properties can help reduce energy consumption by reflecting sunlight and heat away from the building, making it an environmentally friendly choice for roofing applications.

- Q: What are the potential applications of coil-anodized aluminum coils?

- Coil-anodized aluminum coils have a wide range of potential applications due to their unique properties and advantages. Here are some of the key potential applications: 1. Architectural: Coil-anodized aluminum coils can be used in architectural applications such as cladding, roofing, and facades. The anodized coating provides enhanced durability, weather resistance, and color stability, making it suitable for exterior use in different climates. The coils can also be shaped and formed into various architectural elements, offering design flexibility. 2. Transportation: The lightweight nature of coil-anodized aluminum makes it ideal for transportation applications. It can be used for manufacturing parts and components in automotive, aerospace, and marine industries. The anodized coating enhances the corrosion resistance, making it suitable for exterior components and structures. 3. Electronics: Coil-anodized aluminum coils can be utilized in electronics manufacturing. The anodized coating provides excellent electrical insulation, which is crucial in applications requiring high conductivity and insulation. It can be used for manufacturing components like heat sinks, casings, and connectors. 4. Signage and displays: The vibrant and long-lasting colors obtained through coil-anodizing make it an ideal material for signage and displays. The anodized coating ensures color stability against UV radiation and harsh weather conditions, making it suitable for both indoor and outdoor applications. It allows for the creation of eye-catching and durable signage and displays. 5. Furniture and interior design: Coil-anodized aluminum coils can be used in the manufacturing of furniture and interior design elements. The anodized coating provides a smooth, durable, and scratch-resistant surface, making it suitable for applications like tables, chairs, wall panels, and decorative elements. The wide range of available colors and finishes allows for versatile design possibilities. 6. Industrial applications: Coil-anodized aluminum coils can find applications in various industrial sectors. The anodized coating provides enhanced corrosion resistance, which is beneficial in industries like chemical processing, food processing, and pharmaceuticals. It can be used for manufacturing tanks, containers, and equipment that require resistance against harsh chemicals and environments. 7. Energy and sustainable applications: The lightweight nature and durability of coil-anodized aluminum make it suitable for energy and sustainable applications. It can be used in manufacturing solar panels, heat exchangers, and other energy-related components. The anodized coating provides protection against weathering and corrosion, ensuring long-term performance. Overall, the potential applications of coil-anodized aluminum coils are extensive and diverse, ranging from architectural and transportation to electronics, signage, furniture, industrial, and energy sectors. The unique combination of lightweight, durability, color stability, and corrosion resistance makes it a versatile material for various industries and applications.

- Q: I have a 94 Gt Mustang that has had a little work done to it so far. The boy I bought it from had an aftermarket cam put in it, had the heads ported and polished. He also had the heads shaved a little. My question is.........Would having aluminum heads with roller rocker arms installed help it enough to justify doing it. If it would, how Much would it help? I am not exactly sure how much life and duration my cam is running, but it idle pretty rough. I believe my compression is about 9.5 to 1.

- I also believe that the primary benefit of aluminum heads is weight savings...you can port and polish iron heads just the same. I also know that aluminum retains and dissipates heat differently than Iron.

- Q: How are aluminum coils coated to enhance their durability?

- Aluminum coils can be enhanced in terms of durability through various methods of coating. One popular approach is by applying a protective coating, such as polyester or acrylic resin, onto the coils using a technique known as coil coating. This can be achieved through roll coating or spray coating. The purpose of the coating is to create a barrier between the aluminum and external elements like moisture, UV rays, chemicals, and abrasion. By doing so, it prevents corrosion, oxidation, and damage caused by exposure to the environment. The choice of coating type and its thickness can be adjusted according to the desired level of durability and the specific purpose of the aluminum coil. Apart from protective coatings, additional treatments can be applied to aluminum coils to further enhance their durability. These treatments may include pre-treatment processes like cleaning, etching, and chromating, which improve the adhesion of the coating to the aluminum surface. Other treatments may involve the application of primers or topcoats to offer extra protection and enhance the appearance of the coil. Overall, the process of coating aluminum coils enhances their durability by providing a protective layer that can withstand harsh environmental conditions, prolong their lifespan, and preserve their appealing appearance.

- Q: This question asks whether aluminum coils can be utilized in various forms and dimensions.

- <p>Yes, aluminum coils can be used in different shapes and sizes. They are versatile and can be cut, shaped, or rolled into various forms to suit specific applications. Aluminum's malleability allows it to be easily manipulated, making it suitable for a wide range of industries, including construction, automotive, and packaging. The size of aluminum coils can also vary, from small coils used for crafts to large ones used in industrial applications. The versatility of aluminum coils makes them a popular choice for many different projects and industries.</p>

- Q: Can aluminum coils be used in curtain wall systems?

- Yes, aluminum coils can be used in curtain wall systems. Aluminum is a popular material choice for curtain walls due to its lightweight, durable, and corrosion-resistant properties. Aluminum coils can be easily fabricated and formed into the desired shapes and profiles required for curtain wall systems, making them a suitable option for this application.

- Q: What is the typical coil diameter for aluminum coils?

- The diameter of aluminum coils can differ based on the particular application and industry needs. Generally, aluminum coils possess a diameter spanning from 12 to 72 inches. The precise diameter is determined by several factors including the thickness of the aluminum sheet, desired coil weight, and the processing and handling equipment employed. Various industries like automotive, construction, and packaging might have specific coil diameter requirements tailored to their distinctive manufacturing processes and end-use demands.

- Q: What are the common maintenance practices for aluminum coils?

- Some common maintenance practices for aluminum coils include regular cleaning to remove dirt and debris, checking for any signs of corrosion or damage, ensuring proper airflow and ventilation around the coils, and regular inspections to identify and address any potential issues. Additionally, it is important to follow manufacturer guidelines and recommendations for maintenance and to schedule professional servicing when necessary.

- Q: Can aluminum coils be used in the production of military equipment?

- Yes, aluminum coils can be used in the production of military equipment. Aluminum is a lightweight and corrosion-resistant material, making it suitable for various military applications, such as aircraft components, armored vehicles, and weapon systems. Its strength to weight ratio and ability to withstand harsh environments make it an ideal choice for military equipment manufacturing.

- Q: How do aluminum coils contribute to the durability of structures?

- Due to its unique properties and characteristics, aluminum coils greatly enhance the durability of structures. A key factor is aluminum's exceptional resistance to corrosion, unlike other metals that rust or corrode when exposed to moisture or harsh environmental conditions. This corrosion resistance ensures that the building maintains its structural integrity over time, reducing the need for frequent repairs or replacements. Moreover, aluminum coils possess an excellent strength-to-weight ratio, making them a preferred choice in construction. They are lightweight yet strong, providing a high level of structural stability without adding unnecessary weight to the overall structure. This is especially advantageous in earthquake-prone areas or extreme weather conditions, as it allows the building to withstand external forces while minimizing the risk of collapse. Furthermore, aluminum coils are highly malleable, allowing them to be easily shaped and formed into various designs and structures. This flexibility empowers architects and engineers to create innovative and complex designs, giving architects the freedom to explore creative possibilities while ensuring structural integrity. The ability to mold aluminum into different shapes and sizes also increases the efficiency of construction processes, reducing the time and costs associated with building projects. Additionally, aluminum coils are known for their high thermal conductivity, surpassing other commonly used metals in construction. This property enables better heat transfer, resulting in improved energy efficiency and insulation within the structure. By effectively regulating temperature fluctuations, aluminum coils contribute to lower energy consumption, reduced heating and cooling costs, and ultimately, enhanced sustainability of the building. In conclusion, aluminum coils play a crucial role in enhancing the durability of structures. Their corrosion resistance, strength-to-weight ratio, malleability, and thermal conductivity all contribute to the longevity, stability, and energy efficiency of buildings, making them an ideal choice for construction purposes.

Send your message to us

G8 Aluminum Coil - PE Color Coated Aluminium Coils for Decoration AA3003

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords