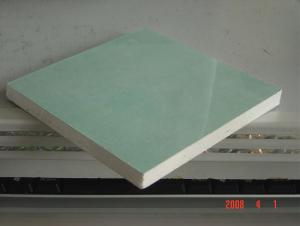

Paper-Faced Drywall Gypsum Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CMAX Gypsum Board Drywall Introduction.

Your drywall can be virtually any shape, anywhere. Choose from a wide range of heavy-duty system options that provide code-compliant performance in both fire rated and non-fire rated applications with labor-saving advantages.

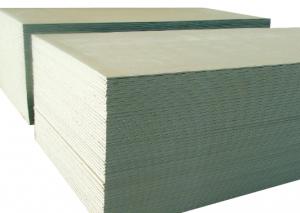

1.Gypsum Board Drywall Specification.

| Convenient Construction | The plaster board can be constructed easily by nailing ,cuting and planing,and thus it becomes the first choice among home decoration materials. |

| Raw material | The gypsum board is characterized for lightness and high intensity,dryness operation, green environmental protect, convenient construction and good processing quality. |

| Size | 595x595 |

| 605x605 | |

| 1200x2400 | |

| 1220x2440 | |

| Thickness | 7,7.5,8,9,9.5,10,12,12.5,13,15,15.9 |

| Surface treatment | Paper/PVC laminated/foil back |

| Production capacity | 10,000m2/day |

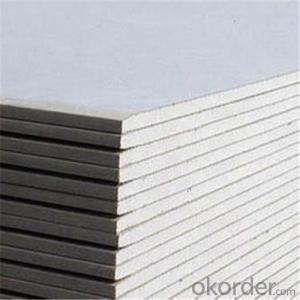

7 .specification

SIZE(mm) | KGS/PC | PCS/20GP | SQM/20GP |

1200*2400*7 | 17 | 1180 | 3398 |

1200*2400*7.5 | 18 | 1150 | 3312 |

1200*2400*8 | 18.2 | 1080 | 3110 |

1200*2400*9 | 22.1 | 970 | 2793 |

1200*2400*9.5 | 22.8 | 940 | 2707 |

1200*2400*10 | 23.5 | 900 | 2592 |

1200*2400*12 | 29.5 | 720 | 2073 |

1200*2400*12.5 | 30 | 710 | 2044 |

1220*2440*7 | 17.55 | 1160 | 3453 |

1220*2440*7.5 | 18.14 | 1130 | 3363 |

1220*2440*8 | 18.58 | 1060 | 3155 |

1220*2440*9 | 22.83 | 950 | 2827 |

1220*2440*9.5 | 23.55 | 920 | 2738 |

1220*2440*10 | 23.83 | 900 | 2679 |

1220*2440*12 | 30.5 | 700 | 2083 |

1220*2440*12.5 | 31 | 690 | 2053 |

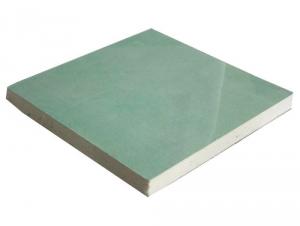

2.Gypsum Board of ceiling & wall partition system.

CMAX System is a modern, non-load bearing and quickly assembled on site. The system consists of Gypsum Board screw fixed to lightweight galvanized metal sections and joint finished with drywall system is suitable for all internal applications for commercial and residential.

Exquisite, Modern and Adjustable

Durable and Standard Quality

Lightweight, Easy to Install and Economic

Applicable to Various Usages as Required

Office buildings requiring extra fine resistance, standard drywall system can provide a half-hour fire resistance. Other drywall Systems are also available to provide resistance up to 2 hours.

Other special properties such as heat insulation wall, high moisture resistant wall, acoustic wall, can also be provided by drywall system.

- Q: Home furnishings commonly used gypsum board how much size? how much is it? Which brand is best?

- Big board Shandong Taishan more. 2440 * 1220mm. The ceiling is made of the standard 600 * 600.

- Q: Silicon calcium board with gypsum board is the same thing? Silicon calcium board Our property here says they sell us a piece of RMB8 But the gypsum board we can take a 3 yuan at least 3 yuan The board is written behind the three big gypsum board but they are hard to tell us that the gypsum board is silicon calcium board Will these two things really be the same thing?

- LZ first clear what is "calcium silicate board" or "silicon calcium board", which is two different things. Calcium silicate board - cement as the main raw material. Silicon calcium board - gypsum as the main raw material. Gypsum board: can be divided into paper gypsum board, decorative gypsum board (that is, silicon calcium board), plant fiber reinforced composite gypsum board and other types. In general, silicon calcium board is a class of gypsum board. The largest gypsum board on the market is the gypsum board, which adds a layer of paper to the surface of the plaster, which reduces the risk of cracking from the plaster itself. The plasterboard has a complete line. Strength is not high. Silicon calcium board is no surface paper, but in the plate inside the glass fiber reinforced materials, all the calcium calcium board is a composite material, and the paper gypsum board is not a composite material. Calcium calcium board than the gypsum board light, and strength High, but the silicon calcium board is not a complete pipeline, the basic or manual operation, which led to the size of the silicon calcium board factory uneven, the product quality gap is huge. Please LZ according to the above to determine whether the calcium calcium board, 8 of the calcium and calcium plate and three of the gypsum board are in the low-end products .8 block calcium calcium board ex-factory price is 3-4 yuan.

- Q: how much does a a sheet of soundbloc plasterboard cost?

- ?8.11 including VAT for a 2400 x 1200: 12.5cm At Joseph Parr in Middlesbrough

- Q: Gypsum board small production equipment how much money

- You intend to do what size, and if it is a small workshop class, may also be hundreds of thousands (registered capital, equipment, plant, personnel, taxes, etc.) If the medium, about 2 million or so (my boss was doing this before, medium-sized, investment 2.58 million) It's hard to say it's big. The The But also to ensure adequate follow-up funds to prevent cash flow is not working

- Q: Gypsum board ceiling expansion joints how to deal with, is a direct patch, or the first gypsum powder stitched in the patch bar. Is it with white latex

- First with gypsum powder slit, in the white latex paste gypsum board caulking paste is a fine semi-water gypsum powder (plaster of graffiti), a variety of additives mixed with gypsum board patchwork processing materials. With high bonding strength, shrinkage deformation is small, good fit, excellent construction performance and so on. Applicable to gypsum board patchwork, fill the nail, large gap. Gypsum board caulking paste mainly by the Western countries to introduce China, since the late 90s of last century in the gypsum board project decoration application. At present the main manufacturers are: Lafarge, can be resistant, dragon, Prades, Jason and so on. □ Main components: plaster, calcium carbonate and additives. □ grass-roots treatment: grass-roots should be a solid without loose, no oil floating ash. □ mixing equipment: mortar consistency to the construction requirements prevail, stirring to be uniform, stirring after 5 minutes and then stirring is appropriate. □ Construction matters: After mixing the mortar used in the use of time, after the barrel should be cleaned again after the preparation of materials, more than the use of time will be cured scrapped. Repair leveling more than 5mm should be sub-sub-scratch. □ Construction temperature: construction temperature above 5 ℃, the curing process is not less than 0 ℃ □ storage and transportation: stored in a cool dry place, shelf life of 12 months. No caking phenomenon, can continue to use. Products non-toxic non-flammable, storage and transportation can be "non-dangerous goods rules" for.

- Q: on the ceiling of an ensuite in our house, the paint is all starting to crack and peel and flake off. I have been given the task of scraping it all off with a metal scraper and it is really tedious and is taking ages to do it. This happened before, so we were told to paint a primer first adn then paint over it with normal paint. It didn't work. Like I said, the wall is a plasterboard, is there anyway to easily strip off the paint? and how can we stop this happening again?

- Once latex paint dries it is very difficult to remove. The only solvent that will work is methlyethyl ketone which you can get at a home center or paint store. If the fabric is cotton you can try removing the paint with MEK if it is synthetic or a blend you will need to test the solvent on a not so visible spot to make sure that it won't damage the fabric.

- Q: I had some water damage to the ceiling of a small bathroom and need to remove the plaster, but I don't want to invest in a reciprocating saw (plus they're scary to use overhead).

- you could also try a rotozip.

- Q: Demolition of gypsum board wall how much money a square meter

- Gypsum board in 8 yuan / ㎡ or so, do the walls need two gypsum board with keel, keel prices in 10 yuan / ㎡ or so, the use of the environment in a dry environment

Send your message to us

Paper-Faced Drywall Gypsum Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords