Gypsum Board for Wall

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1Container m²

- Supply Capability:

- 300Containers/Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

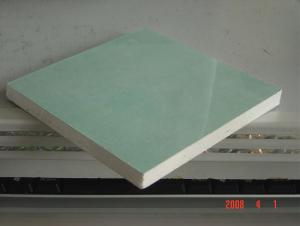

Description of Gypsum Board:

1.We have three kinds of gypsum board, regular gypsum board, fire-proof gypsum board and moisture resistant gypsum board. And our product are mainly used for Ceiling system, Partitio system, Dry lining system and we also provide its allied system such as: Channels, joint compound, joint tape, screws and so on.

2.Gypsum board edge:

Tapered edge (recessed edge) And Square edge (straight edge)

Technical data of Gypsum Board:

DENSITY: | AS PER GB/T9775-1999 |

BREAKING STRENGTH: | AS PER GB/T9775-1999 |

ANTI-FIRE FUNCTION:

| ≤30 MINS AS PER GB8624-1997 |

COMBUSTION PERFORMANCE:

| NON-COMBUSTIBLE MATERIAL |

SIZE TOLERANCE:

| LENGTH/WIDTH≤±2.0MM |

MOISTURE CONTENT:

| ≤2% |

HEAT COEFFICIENT:

| 0.16-0.18 |

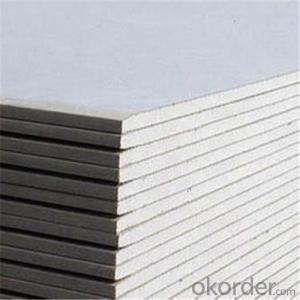

Raw Materials of Gypsum Board:

Using high purity gypsum powder as main material and mixed with fiber and highquality additive

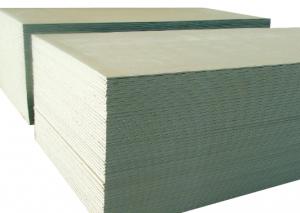

SIZE: (mm)1200*2400 1220*2440 1200*3600 1220*3600 1200*2500 1220*2500

Thickness: ( mm) 6.4 to 16

Applications of Gypsum Board:

1: Ceiling system,

2: Partition system,

3: Dry lining system

Package of Gypsum Board

1.Naked with bulk in container by hand

2.Load with pallet by forklift

Poduct flow:

We have 10 product line to meet our diary order demands,60 containers per month is our production capacity, we are your final wise choice.

- Q: I'm having the kitchen done and are having plasterboards put up 'cos the plaster that is on at the moment is so old, dry and flaking off in large peices. Just wondered if these walls will be strong enough to hold up my wall units. Pleeeeeaaase let me know.

- How are the boards being fitted on battens or dot and dab?Either way you can use cavity fixings if there is sufficient space behind the plaster board ( I use the brolly type)whatever you do dont use those stupid corkscrew things they wont take the weight.If there is very little gap then the normal plugs and screws will do just make sure to use long enough screws(size matters)I normally use a size 10 screw and vary the length accordingly and dot and dab the same plugs and screws. It may also pay to fit a spacer behind the screw through the pasterboard to the wall to stop boards distorting but without seeing the job its hard to tell the best for your application.

- Q: There's a substantial dent (bordering on being a deep crack/hole) in the middle of a 3 square meter piece of painted plasterboard. I need to repair it with something durable as it's in a prominent place and thus am not sure plaster will suffice. On-top of that it will need to be painted. What should I use?

- I would paint it with a flat latex paint. That will help hide some of your mistakes. Good luck!

- Q: Silicon calcium board and gypsum board price?

- First of all, the price is a regional difference, the best in the local building materials market inspection. Second, the use of two kinds of plates are different, calcium calcium board is not afraid of water, can be used for the bathroom and other areas of wet areas, but because of its construction is not convenient, it is generally more common with water-resistant gypsum board. The gypsum board is more commonly used in the top and wall decoration materials, because of its easy construction characteristics, it was recognized and widely used. In terms of cost, silicon calcium board is generally 2 to 3 times the gypsum board, which is why the use of gypsum board more reasons.

- Q: please help!

- u need to have the right brackets and self tapping plaster bord screws to find good fixing place by tapping wall till u find a good fixing place

- Q: Gypsum board wall can be installed after the door suction it?

- Due to restrictions on the gypsum board material recommended Do not install the door in the wall can be installed in the wall from the wall ten cm on the floor

- Q: whats the difference between gypsumboard and plasterboard?

- Gypsum board will fall apart when it gets wet and plaster board won't.

- Q: What is the difference between waterproof gypsum board and moisture-proof gypsum board?

- Moisture-proof gypsum board and waterproof gypsum board difference 1. Ordinary waterproof paper gypsum board is based on the traditional paper gypsum board on the basis of innovation and development of a new product, not only has all the advantages of gypsum board, but also in the gypsum board plate core to add some additives, making Waterproof time is longer. 2. Positioning point waterproof paper gypsum board Positioning point waterproofing Based on the traditional water-resistant paper gypsum board on the basis of innovation and development of a new product, not only has the traditional water-resistant plaster board all the advantages, but also to solve the traditional water-resistant paper gypsum board construction process artificial Belt positioning to bring the labor intensity, the product is easy to damage, construction efficiency is low, the quality of the project can not fully guarantee the problem. 3, moisture-proof gypsum board and waterproof gypsum board almost the same, but the waterproof gypsum board core and face paper are waterproof, not directly exposed to the wet environment, nor direct water or soak for a long time. Therefore, waterproof gypsum board and moisture-proof gypsum board is different.

- Q: it is always a dry wall

- Liquid Nails makes a specific drywall adhesive.... which should work...as long as you think you'll NEVER have to remove that drywall for any reason. If this is a below grade wall.... do yourself a favor....don't glue drywall to the brick.

- Q: I play alot of guitar and my mum gets fed up of the noise, her boyfriend works nights so he sleeps most of the day and their bedroom is right next to mine and the walls are paper thin, just 2 sheets of plasterboard with a 4 gap i think. Does anyone know how i can soundproof it without tearing it down?thanks

- There are other construction methods to lessen sound transmission between rooms...rebuild the wall with offset staggered studs so that the sounds from one room are not transmitted through the studs and drywall into the next room. One side of the wall is attached to one row of studs and the other side has another row of studs which are offset an inch or so....any vibrations of sound cannot pass through the studs. Placing eggcarton type foam on the walls can deaden the noise a little but the most effective way is to rebuild the walls between the adjoining rooms...or play when he's not around. Or play the guitar with headphones....or another room further away/garage?.

- Q: Im going to put up plasterboard for the first time and was told their is some kind of Adhesive to hold plasterboard on wall. It sounds easier than nails or screws because its onto a brick wall.Thanks.

- I think i saw some at the home depot the last time i went. check it out

1. Manufacturer Overview

| Location | Shandong,China (Mainland) |

| Year Established | 1997 |

| Annual Output Value | Above US$100 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe South Asia |

| Company Certifications | Business license;Foreign trade record certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | average |

Send your message to us

Gypsum Board for Wall

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1Container m²

- Supply Capability:

- 300Containers/Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords