Best Drywall Gypsum Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

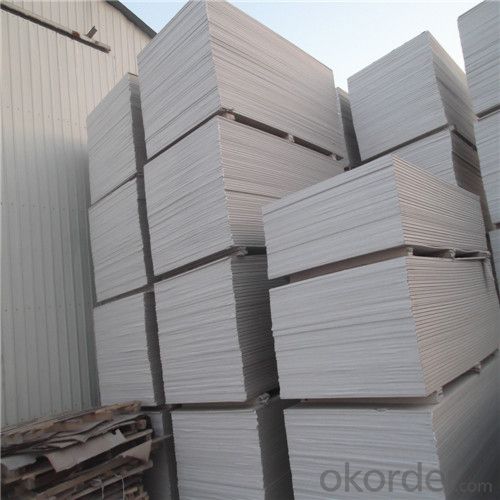

paper-faced gypsum board panel standard

a.competitive prices

b.size:1200*2400/1220*2440mm

c.fire rate is B1

d.ISO9001:2008

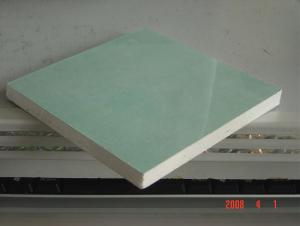

paper-faced gypsum board/wall panel standard size

1 .firep roof: The fire rating of the gypsum ceiling board is B1.

2 .safe : The raw materials is environment-friendly materials. Our products are the ideal green building materials.

3 .artistic: Elegant in appearance, it can be used in schools, hospitals, conference rooms and so on

4 .long service life: We put the glass fiber inside, it can make gypsum ceiling deformation, high strength, wear resistance.

5 .convenient:Our products can be used in a complex environment and easy to clean.

6 .sell well: Our factory is a manufacturer of building materials with a history of more than ten years. Our products sell well both at home and abroad.

7 Loading

Transportation: By 20'Container

sizes | Quantity |

2400*1200*8 | 1150(20FCL) |

2400*1200*9 | 970(20FCL) |

2400*1200*9.5 | 950(20FCL) |

2400*1200*12 | 750(20FCL) |

2430*1210*8 | 1150(20FCL) |

2430*1210*8.5 | 1100(20FCL) |

3000*1200*12 | 1050(40 FCL) |

3000*1200*9.5 | 850(40FCL) |

Loading port: Qingdao port

Origin: Shandong china

Exquisite, Modern and Adjustable

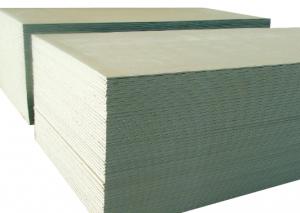

CMAX drywall system provides smooth, seamless and crack-free wall surface. Thanks to the distinctive property of CMAX gypsum Board, it allows easy further decoration by either painting or wallpaper work. Moreover, a renovation can be done easily without any disturbance of office building structure.

Durable and Standard Quality

Materials and accessories of CMAX wall system are manufactured by state of the art technology in accordance with international standards, such as, British Standard and The American Society for Testing and Materials. Customers therefore can be assured of safety, standard quality and high durabiltity of PRANCE Wall systems.

Lightweight, Easy to Install and Economic

CMAX wall weight much less than masonry partitions of comparable thickness, thus providing real savings in structural design. This enables quick and easy installation, and produces time and cost savings.

Specially Designed and Patented Materials of Gyproc

High quality galvanized CMAX frame metal sections of drywall system are manufactured by state of the art technology called drywall STEEL, to reinforce the cross section of metal sections. C-Stud is also specially designed to be easy when connected, which suits applications requiring extra strength or for length extension of C-Stud. Ready-punched holes from factory provide excellent incorporation of services.

Applicable to Various Usages as Required

CMAX wall system can be designed to suit various types of office application.

Office buildings requiring extra fine resistance, standard drywall system can provide a half-hour fire resistance. Other drywall Systems are also available to provide resistance up to 2 hours.

Other special properties such as heat insulation wall, high moisture resistant wall, acoustic wall, can also be provided by drywall system.

- Q: I need to put up a platerboard in bathroom cover cover up old loft hatch? do i need to dampproof this somehow as in bathroom where there is a lot of steam? or can i just put this up and skim it over?

- put up moisture resistent dry wall if you can find the one that is purple at your supply store,use it it has a mildiside in it ,if not get green-board! CAUTION THOUGHT when putting up over existing, you need a different screw length (based on what you are going through!******** regular wall board isn't fine!!!!!! source------ builder with common sense!!!!!

- Q: theres a wall in my house thats a complete mess really old cracked plaster .... i know i can bond coat it and then finsh plaster it / but just wondered can you just pva... then dot and dab with drywall adhesive and board it - scrim the joints and finish plaster that? i know i'l loose probabily near on 50mm of wall but i think the finsh would be better and easier with les mess???

- screw studs to the wall vertically and screw board to studs then finish plaster

- Q: hi, i took the tiles off but underneath were more tiles and in some areas plaster over more tiles and some plasterboard , ha its a right mess, whoever did it was dodgy, do i have to taake all this off right back to the brick and get someone to plaster it fresh or can i just hide all this with plasterboard and put new tiles on this? please help

- of course been there, done that

- Q: Construction method of wood keel gypsum board

- Simple description The production process is: first with wooden keel frame structure, ceiling wood keel should be coated with fire retardant paint, hanging on the main keel. Ladder-type ceiling with blockboard and wood composition. Wood keel do a good job after the paper gypsum board, paper gypsum board and keel connection must use self-tapping screws, screw head must enter the board 2mm or so, is strictly prohibited using gun nail, because the paper gypsum board strength is low, Small surface, easy to cause paper and gypsum board layer, and the paint construction caused great trouble. Gypsum board splicing should be left about 5mm gap, to prevent the damp expansion caused by the top of the arch. Paste gypsum board base treatment when applied anti-rust paint the screw point, otherwise the rust will penetrate the surface. And then the patchwork with elastic putty approved flattened with a white bandage, then full approval, the general approved scraping two to three times, dry after grinding smooth, and finally coated with paint. For the installation of the ceiling of the ceiling due to the low strength of the plaster board, so gypsum board and keel should be added between a layer of plywood, so that the installation and maintenance of the lamp when you can prevent damage to the plaster board, Of the installation of fastness.

- Q: whats the difference between gypsumboard and plasterboard?

- Gypsum board will fall apart when it gets wet and plaster board won't.

- Q: Do you use a gypsum board to make a wall that is neither strong nor clean?

- Gypsum board can generally do partition, sound insulation is very good. And the construction is convenient. But the wall can not hang something only. When the wall is made, it is usually pre-installed keel frame, and then the gypsum board installed on the keel, and then paint or paste wallpaper, and the concrete wall looks no different. As long as the keel is strong, then the gypsum wall is very strong. However, because the essence of gypsum hard, but not suitable for hanging in the above things, so similar to the frame painting is not suitable for direct suspension, unless you find the keel, nail on the keel above Caixing. If there is no hanging weight, then the gypsum wall is still very practical.

- Q: Just Curious

- No. It will not melt due to heat as it is a fireproof material.

- Q: I've got a heavy bathroom cabinet with mirror to an internal plasterboard wall. I was thinking of using plastic plasterboard plugs, for the two screws that hold the whole cabinet.is this going to be strong enough?

- Heavy Duty Plasterboard Wall Fixings

- Q: I have moved into a new house which has an extension, I have found that the extension was not insulated. I wish to cut out some plasterboard, lay the insulation and then replace. Any ideas? There are 4 sunken spotlights in the ceiling which are at least 1 metre apart.

- I would recommend going with blown in cellulose insulation. You can drill 2 inch holes in the drywall, blow in the insulation, patch the holes and save a ton of money, time and materials. Cellulose is safe, cheap, easy to do yourself. Drill for walls, use the access door or put one in to do the attic. You may need to protect the areas around the ceiling lights due to heat dangers.

- Q: Gypsum board belongs to what product category

- Gypsum board is a kind of material made of building gypsum as the main raw material. It is a light weight, high strength, thinner thickness, easy processing and insulation and fire insulation and other good performance of the building materials, is currently focused on the development of one of the new lightweight sheet

Send your message to us

Best Drywall Gypsum Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords