P-3 inch non clogging high suction self priming diesel water pump bare

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 120 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Introduction

Main datas:

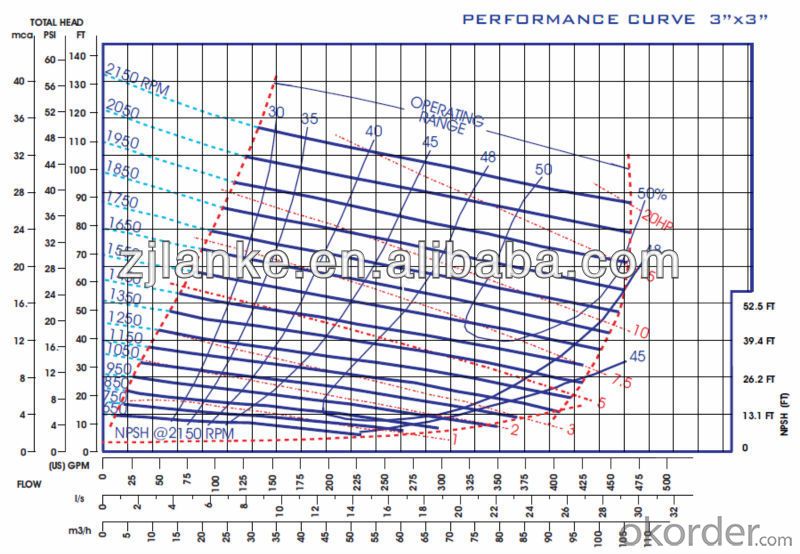

Capacity( flow rate) : 15 ~ 165 m3/h

Head : 2~35 m

Speed:650 ~ 1950 rpm

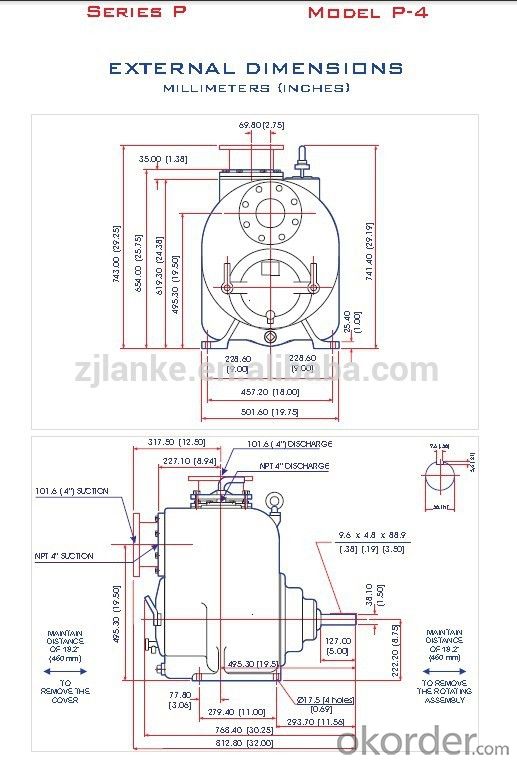

Impeller diameter:247.65 mm

Pump weight: 260 kg /280 kg

Power:1 ~ 30 hp

Quotation

Cast iron pump body+ Ductile impeller+ NSK Bearing+Mechanical seal

FOB NINGBO 1400USD/PCS

Advantage :

Big pump body pass 76.2mmsolid ,high suction head 7.6 m

Convenient repair and clean (a person ten minutes)

Removable cover plate ,replaceable wear plate

OEM ,L/C ,TT ,O/A ,D/P,D/A and so on

CE ,TUV .ISO

NAME: P series 4 inch non clogging high suction self priming diesel water pump

Self Priming pump units are available for Solids Handling or Clear Liquid service.

Typical mounting configurations are Engine Driven for Skid or Trailer Mounted packages

and Frame Mounted Electric Driven. Pumps also are available in a variety of different metallurgies.

1) Main Character

1.Beautiful shape and fine structure,reliable performance.

2.With strong capacity of delf priming, no need to equip with flap valve.

3.Non-clog, and with powerful capacity of passing big solid..

4.The hole can make sure that stronger sewage can be cleaned quickly when pump is jammed.

5.The unique lubrication oil mechanical seal cavity makes the performance more reliable.

6.Special check valve structure can make the pump working quickly.

7. When working, the gas and liquid works together .

8. Low rotary speed,reliable operation,long time usage, easy to maintenance.

9.Advanced pressure protector make pump the pump work safe.

2) Application Area

1. Municipal project, sewage project, instruction project.

2.Uptown,hospital, hotel sewage transportation.

3.Classification of municipal sewage factory treatment and concentrate system engineering.

4. Factory and contaminated water delivery.

3) Industries Served

♦ Construction | ♦ Industrial | ♦ Municipal |

♦ Agricultural | ♦ Mining | ♦ Dewatering |

♦ Industrial Waste | ♦ Sewage | ♦ Oil Field |

♦ Petrochemical | ♦ Paper Mills | ♦ Processing |

4)Parameter

5) Mounting Configuration

♦ Frame Mounted

♦ Base Mounted Electric Driven

♦ Engine Driven SAE Mounted

♦ Engine Driven Skid or Trailer Packages

♦ Horizontal or Vertical V-Belt Driven

Samply available: 7~10days.

Qty: 1pc, only pump head is provided.

Price: US$100~200

OEM is welcome

OEM expierence: more than 10 years.

Countries: Germany, U.S.A, Spain, Italy, United Kingdom etc

Warranty: the whole pump is guaranteed within 1 year, the pump's spare parts are guranteed for 3 months from the date of delivery.

For more information, please do not hesitate to contact me.

The information should be including inquiry as following:

1.Pump's flow rate

2.Pump's Head (Pressure)

3.Driven Mode: By electric motor or diesel engine or bare shaft etc

4.Power and rotary speed

5.Suction lift for self priming pump

6.Temperature of liquid if you can provide

Upon the receipt of the pump's parameter, we can send our quotation to you within 24 hours.

Or the condition of pump station would be provided.

♦FAQ:

1. Q: Can I know more about your products?

A: Pls view our website: www.lanco.cc.

2. Q: What’s your MAQ of this item?

A: 1~2PCS

3. Q: What is the lead time?

A: 10~30 days after receiving your payment,depends on pumps.

4. Q: where is your loading port?

A: Ningbo, China port

5. Q: Are you a manufacturer or trading company

A: We are a manufacturer specialize in water pump and other pumps more than 20 years.

For more information, please contact me.

Components Display

- Q: What does "anti pump" mean in pump operation?

- The working process of the main oil cylinder pushing back and forth against the pump when the S valve (C valve or valve or gate valve skirt) reverse swing, so the piston suction concrete cylinder is in the ash conveying pipe is exactly opposite is the pump suction pump (hopper is concrete and push into the hopper, the desizing)

- Q: If you use an ordinary 15W submersible pump, put it in the tank, if the leakage, the fish will hang it?

- If the fish tank is made of metal, the fish tank is grounded or connected to the zero line, and then the fire line is put into the water, then your fish will be electrocuted immediately. Go back to the submersible pump, submersible pump line and the zero line very close, even if the firing line and the zero line at the same time the leakage occurs, fish could not swim between the firing line and the zero line, so the tank submersible pump leakage will cause the following hazards: 1, electric shock. 2, submersible pump short circuit. 3, the submersible pump serious fever, resulting in water temperature tank.

- Q: What is the relationship between the minimum suction vacuum of a pump and the required cavitation?

- When the pump is working, the liquid at the inlet of the impeller, due to a certain vacuum pressure will produce steam, the vaporization of the bubble in liquid particles under the impact of movement, the impeller and other metal surface erosion, thereby damaging the impeller and other metal

- Q: What's the difference between non negative pressure and variable frequency water pump?

- When peak water is used, the fluctuation of water pressure will be the same for customers! Because the key to the fluctuation of hydraulic pressure is the flow rate of the pump and the lift of the pump. As long as the flow of the selected pump is large enough, the tank is large enough, the lift head is suitable, and the pressure fluctuation is relatively small. And the selection of non negative pressure and frequency conversion pump group is not directly related. If the municipal tap water pressure and water sufficient (large enough diameter), the use of non negative pressure is better. If the municipal tap water pressure and water shortage, you can only use the frequency converter pump + water tank, no negative pressure can not be used.

- Q: Shielding pump is the main drawback of electricity? How much does it cost more than an ordinary centrifugal pump? Is there any noise in the running of the canned pump? How much is it lower than the noise of the common centrifugal pump?

- The ordinary centrifugal pump is driven by coupling the pump impeller shaft is connected with the motor shaft, the impeller and the motor rotates while working and shielding pump is a kind of non seal pumps, pump and motor is sealed in a medium filled by pumping the pressure vessel, the pressure vessel only static seal and, by a group of wires to provide a rotating magnetic field and rotor drive. The structure eliminates the rotary shaft sealing device of the traditional centrifugal pump, so the utility model can be completely free from leakage.

- Q: Pump operator's responsibility 10Sharing the rules, responsibilities, etc..

- 1., consciously abide by the traffic control department management rules, to achieve civilized driving, safe driving.2. responsible for the daily maintenance, cleaning and cleaning of the pump truck, and ensure the equipment is in good condition.

- Q: I want to know the concrete under 60 type pump performance, it is mainly the pump long spiral bored piles, such as the diameter of the pump, transportation distance, pumping height and so on, thank you!

- Specification for concrete cylinders:Bore * stroke mm 200 * 1650Hopper capacity L 800Feeding height mm 1400Motor model Y2-280M-4Power kw 90Rated voltage V 380Rated speed r/min 1480Soft starter withoutHydraulic system open-loop

- Q: Direct connection pump What is straight pump and non direct pump? What's the difference in structure?

- The direct connected pump impeller is directly mounted on the motor shaft, and the non direct connected pump and motor are two shafts, and the two shafts transmit torque through the coupling

- Q: How many concrete pump tube diameter

- Different pipe diameter is different, most of the 125, there are 150. Now we have the smallest pump on the market, with a pipe diameter of 100.

- Q: Do you have a suction pump higher than 9 meters?

- This screw self-priming pump suction process can be more than ten meters or more, my family is using this

Send your message to us

P-3 inch non clogging high suction self priming diesel water pump bare

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 120 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords