Our Cheap Hot-dip Aluzinc Steel Building Roof Walls

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Aluzinc Steel Building Roof Walls

1. Description of the Hot-dip Aluzinc Steel:

Hot-dip aluzinc steel structure is composed of aluminum-zinc alloy, consisting of 55% aluminum, 43% zinc and 2% at 600 ℃ silicon solidification temperature and composition, the entire structure is made of aluminum - iron - silicon - zinc, to form a dense quaternary crystals an alloy.

Hot-dip aluzinc steel has many excellent features: strong corrosion resistance, is three times the pure galvanized sheet; zinc surface with beautiful flowers, can be used as a building outside board.

Applications of hot-dip aluzinc steel:

1)Building: roof, walls, garages, soundproof walls, pipes and modular housing.

2)Automotive: muffler, exhaust pipes, wiper accessories, fuel tank, truck boxes, etc.

3)Appliances: refrigerator back, gas stove, air conditioners, microwave oven, LCD frame, 4)CRT-proof band, LED backlight, electrical cabinets, etc.

5)Farm: barn, sheds, silos, piping and other greenhouse.

6)Other: breaking heat insulation cover, heat exchangers, dryers, warm water, etc.

2.Main Features of the Hot-dip Aluzinc Steel:

• Excellent corrosion resistance

• High temperature oxidation resistance

• High hot reflectance

• Good manufacturability

•Beautiful appearance

•Surface coating

•Cost-effective

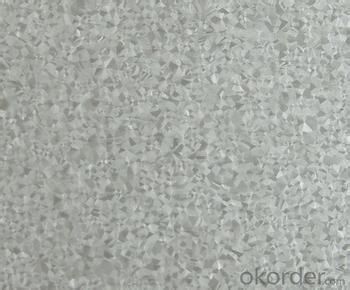

3.Hot-dip Aluzinc Steel Images

4.Hot-dip Aluzinc Steel Specification

AVAILABLE SPECIFICATION

HOT-DIP ALUZINC STEEL COILS | |

THICKNESS | 0.16mm-3.5mm |

WIDTH | 1250mm MAX |

COATING MASS | 30g/ m2-185 g/ m2 |

SPANGLE | Regular Spangle, Minimized Spangle, Zero Spangle |

SURFACE TREATMENT | Chromated / non-chromated, Oiled / non-oiled, Anti Finger Print |

COIL INNER DIAMETER | 508mm or 610mm |

HOT-DIP ALUZINC STEEL COILS | |||

COMMERCIAL QUALITY | ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 |

STRUCTURE STEEL | SS GRADE 230 SS GRADE 255 SS GRADE 275 SS GRADE 340 SS GRADE 550 | S220GD+AZ S250GD+AZ S280GD+AZ S320GD+AZ S350GD+AZ S550GD+AZ | SGLC400 SGLC440 SGLC490 SGLC570 |

2.5.FAQ of Hot-dip Aluzinc Steel

We have organized several common questions for our clients,may help you sincerely:

1.What advantages does your company have?

Cement : Annual capacity of 400 million tons, No. 1 in the world

Fiberglass: Annual capacity of 1 million tons fiberglass, No. 1 in the world.

Composite Materials — Carbon Fiber: Annual capacity of 10,000 tons PAN precursor and 4,000 tons carbon fiber, No. 1 in China

Composite Materials — Rotor Blade: Annual production capacity of 15,000 pieces, No.1 in China, Top3 worldwide

Glass: CNBM owns about 20 modern float glass product`ion lines, With annual capacity of 10 million square meters glass.

Light Weight Building Materials: Annual capacity of 1.65 billion square meters of gypsum board, No. 1 in the world.

Commercial concrete: Annual capacity of 0.35 billion cubic meters, No. 1 in the world.

Refractory Material: Annual capacity of 40,000 tons casting refractory, No.1 in the world.

2.What advantages do your products have?

Firstly, our base material is of high quality, Their performance is in smooth and flat surface,no edge wave ,good flexibility.

Secondly, high quality zinc ingoats, 97.5% zinc,1.5% silicon,1% others, the same zinc coating measured by metal coating thickness or by zinc weight

Thirdly, high precision: Tolerance strictly according to ASTM or JISG standard even more rigid.

We have full stes of testing equipment(for t best, cupule,chromatism,salt spray resistance, etc) and professional engineers.

- Q: Want to get stainless steel sink. I want quality, durability, quiet, etc. Any suggestions??

- Yes, it’s a good idea to look for the best brand of stainless steel sink as it is used in various purposes regularly. Top brand of stainless steel is naturally longer lasting and capable of bearing lot of pressure then normal stainless steel sink. You must see top brands as well as their prices before buying any.

- Q: What are the factors to consider when selecting steel coils for a specific application?

- When selecting steel coils for a specific application, several factors need to be considered. Firstly, the desired strength and durability requirements of the application should be assessed to determine the appropriate grade of steel. Other important factors include the thickness and width of the coils, as well as their surface finish and flatness. The intended use and environment of the application, such as exposure to corrosion or extreme temperatures, should also be taken into account. Additionally, cost considerations and availability of the desired steel grade should be considered during the selection process.

- Q: How do steel coils contribute to thermal insulation in buildings?

- Steel coils do not contribute to thermal insulation in buildings. In fact, steel is a good conductor of heat, so it can actually transfer heat rather than insulate against it.

- Q: How are steel coils cut into smaller sizes?

- Steel coils are cut into smaller sizes using a machine called a slitting line. This machine employs a set of circular blades that cut through the steel coil, creating narrower strips or sheets of the desired size. The slitting line can adjust the width of the cuts and can also remove any rough edges or burrs.

- Q: What are the different methods of coil leveling?

- Various industries commonly utilize several methods for coil leveling. These methods encompass: 1. Roller leveling: By passing the coil through a sequence of rollers, pressure is applied gradually, resulting in the gradual flattening of the coil. The rollers can be adjusted to exert varying levels of pressure, allowing for precise control over the leveling process. 2. Stretch leveling: This technique subjects the coil to tension forces, elongating the material and eliminating internal stresses. As the coil is stretched while passing through rollers, a more uniform and flat surface is achieved. 3. Temper leveling: Involving the heating of the coil to a specific temperature followed by rapid cooling, this method helps equalize stresses within the coil and enhance its flatness. Temper leveling is often employed for high-strength steels. 4. Roller leveling with leveling rolls: This approach utilizes additional leveling rolls placed above and below the main leveling rollers. These rolls apply pressure to specific areas of the coil, rectifying any unevenness or distortions. 5. Tension leveling: This method involves applying tension to the coil during processing. The tension aids in straightening and flattening the material, resulting in a more even and flat surface. 6. Precision leveling: Employed for high-precision applications necessitating extremely flat and uniform coils, precision leveling combines roller leveling, stretch leveling, and other corrective measures to attain the desired flatness. Each of these methods possesses unique advantages and limitations. The selection of a particular method depends on factors such as the type of material being leveled, the required flatness tolerance, and the intended application of the coil.

- Q: How are steel coils used in the manufacturing of storage racks?

- Steel coils are used in the manufacturing of storage racks by being processed and shaped into various components such as beams, bracings, and shelves. These components are then assembled to create sturdy and durable storage racks that can safely hold and organize heavy items in warehouses, industrial facilities, and retail stores.

- Q: Can steel coils be recoiled?

- Yes, steel coils can be recoiled. The process of recoiling involves rewinding the steel coil onto a different reel, typically to adjust the coil size or to improve its shape.

- Q: I've heard different things bout them, though I do not know this. Oh, and if you know where you can buy some raw or get custom made stuff out of black steel please let me know it would be greatly appreciated. Oh and my friend told me there is a black steel that can be sharpened and silver will be underneath, is this also true? Thank you very much for answering ^^

- black steel and black tron are not same.

- Q: So carbon is gas that brakes down to hydrogen and helium before going in...And steel can go a little farther towards sun before evaporating.. 200 degrees closer at leastso steel is full of a heavier gas bomb in my hypothesis and needs to be broken up outside stars(broken down)Is steel capable of going into sun with an element thats wrong wayLike iron has no air to boil outAnd steel goes just as far with carbon in it..Other words can u answer me with..Carbon is already IN the sun and is capable of braking down Carbon INSIDE the star/sunOnly way I see steel boiling is inside and it releases carbon gas at once..carbon bomb

- Hi: okorder /

- Q: What are the common surface treatments for galvanized steel coils?

- Some common surface treatments for galvanized steel coils include passivation, chromate conversion coating, and painting. Passivation helps to enhance the corrosion resistance of the galvanized coating, while chromate conversion coating provides additional protection and improves adhesion for subsequent paint coatings. Painting can be done to enhance aesthetics or to provide additional corrosion protection, depending on the specific requirements of the application.

Send your message to us

Our Cheap Hot-dip Aluzinc Steel Building Roof Walls

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords