Hot-Dip Aluzinc Steel Building Roof Walls in Low Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-Dip Aluzinc Steel Building Roof Walls in Low Price

1. Description of the Hot-Dip Aluzinc Steel:

Hot-dip aluzinc steel structure is composed of aluminum-zinc alloy, consisting of 55% aluminum, 43% zinc and 2% at 600 ℃ silicon solidification temperature and composition, the entire structure is made of aluminum - iron - silicon - zinc, to form a dense quaternary crystals an alloy.

Hot-dip aluzinc steel has many excellent features: strong corrosion resistance, is three times the pure galvanized sheet; zinc surface with beautiful flowers, can be used as a building outside board.

Applications of hot-dip aluzinc steel:

1)Building: roof, walls, garages, soundproof walls, pipes and modular housing.

2)Automotive: muffler, exhaust pipes, wiper accessories, fuel tank, truck boxes, etc.

3)Appliances: refrigerator back, gas stove, air conditioners, microwave oven, LCD frame, 4)CRT-proof band, LED backlight, electrical cabinets, etc.

5)Farm: barn, sheds, silos, piping and other greenhouse.

6)Other: breaking heat insulation cover, heat exchangers, dryers, warm water, etc.

2.Main Features of the Hot-dip Aluzinc Steel:

• Excellent corrosion resistance

• High temperature oxidation resistance

• High hot reflectance

• Good manufacturability

•Beautiful appearance

•Surface coating

•Cost-effective

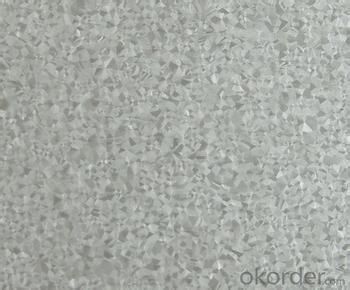

3.Hot-dip Aluzinc Steel Images

4.Hot-dip Aluzinc Steel Specification

AVAILABLE SPECIFICATION

HOT-DIP ALUZINC STEEL COILS | |

THICKNESS | 0.16mm-3.5mm |

WIDTH | 1250mm MAX |

COATING MASS | 30g/ m2-185 g/ m2 |

SPANGLE | Regular Spangle, Minimized Spangle, Zero Spangle |

SURFACE TREATMENT | Chromated / non-chromated, Oiled / non-oiled, Anti Finger Print |

COIL INNER DIAMETER | 508mm or 610mm |

HOT-DIP ALUZINC STEEL COILS | |||

COMMERCIAL QUALITY | ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 |

STRUCTURE STEEL | SS GRADE 230 SS GRADE 255 SS GRADE 275 SS GRADE 340 SS GRADE 550 | S220GD+AZ S250GD+AZ S280GD+AZ S320GD+AZ S350GD+AZ S550GD+AZ | SGLC400 SGLC440 SGLC490 SGLC570 |

5.FAQ of Hot-dip Aluzinc Steel

We have organized several common questions for our clients,may help you sincerely:

1.What advantages does your company have?

Cement : Annual capacity of 400 million tons, No. 1 in the world

Fiberglass: Annual capacity of 1 million tons fiberglass, No. 1 in the world.

Composite Materials — Carbon Fiber: Annual capacity of 10,000 tons PAN precursor and 4,000 tons carbon fiber, No. 1 in China

Composite Materials — Rotor Blade: Annual production capacity of 15,000 pieces, No.1 in China, Top3 worldwide

Glass: CNBM owns about 20 modern float glass product`ion lines, With annual capacity of 10 million square meters glass.

Light Weight Building Materials: Annual capacity of 1.65 billion square meters of gypsum board, No. 1 in the world.

Commercial concrete: Annual capacity of 0.35 billion cubic meters, No. 1 in the world.

Refractory Material: Annual capacity of 40,000 tons casting refractory, No.1 in the world.

2.What advantages do your products have?

Firstly, our base material is of high quality, Their performance is in smooth and flat surface,no edge wave ,good flexibility.

Secondly, high quality zinc ingoats, 97.5% zinc,1.5% silicon,1% others, the same zinc coating measured by metal coating thickness or by zinc weight

Thirdly, high precision: Tolerance strictly according to ASTM or JISG standard even more rigid.

We have full stes of testing equipment(for t best, cupule,chromatism,salt spray resistance, etc) and professional engineers.

- Q: What are the different methods of coil rewinding for steel coils?

- There are several different methods of coil rewinding for steel coils, including manual rewinding, semi-automatic rewinding, and fully automatic rewinding. In manual rewinding, the coils are rewound by hand using a winding machine or tool. Semi-automatic rewinding involves the use of a machine that assists with the rewinding process, but still requires some manual intervention. Fully automatic rewinding, on the other hand, involves the use of advanced machinery that can automatically rewind the steel coils without any manual intervention. These different methods offer varying levels of efficiency, speed, and precision in the coil rewinding process.

- Q: Why is iron used to create steel? Why not other elements?

- iron came before steel. iron is what was discovered that, under certain circumstances, became a stronger metal: steel. that is why. its like asking why copper is in bronze. because what we call bronze, is an alloy of copper and tin. if you give a more detailed question, i may be able to give a more detailed answer.

- Q: What are the common defects found in steel coils?

- Some common defects found in steel coils include surface defects like scratches, indentations, and pits, as well as internal defects such as cracks, lamination, and segregation. Other defects can include edge wave, coil breaks, and coil set.

- Q: What is the accuracy of steel tape inspection?

- The project is through the detection of steel tape, steel tape each batch have the error him different, so do projects each into a batch of steel tape has to go through the inspection department, let this batch of steel tape has reached the same error range. All the measuring tools in this project are unified into these steel tape measures, so that the measurement error is guaranteed.

- Q: How are steel coils used in the manufacturing of construction equipment?

- Steel coils are used in the manufacturing of construction equipment as they serve as a primary raw material for the fabrication of various structural components such as frames, bodies, and chassis. These coils are typically processed through cutting, bending, welding, and shaping techniques to create the necessary parts that provide strength, durability, and stability to construction machinery.

- Q: I'v had 5 people at school say steel is stonger than Titanium and some(5) kids at school say titanium stronger then steel but i looked it up on the internet and i got soem web sites that say steel is stronger then titanium and some sites that say titanium is stonger then steel sooooo???? witch one is strongerPS i no tungsten is stronger then steel.... and titanium.................

- Titanium has better high temperature strength than steel. Titanium doesn't resist shocks like steel can. It's more brittle. It's also far more difficult to weld. Titanium must be welded in an oxygenless environment. The average strength of steels that are made is under that of titanium. However, the strongest steel is stronger than the strongest titanium. Steel is the only viable building material. Titanium is too rare, expensive, and hard to handle for structures of great height. Hope this helps. Peace and Love.

- Q: How are steel coils used in the production of steel plates?

- Steel coils are a critical component in the production of steel plates. They serve as the primary raw material for manufacturing steel plates. The process begins with the production of steel coils, which are created by heating and cooling molten steel to form thin, flat strips. These coils are then processed further in a rolling mill, where they are passed through a series of rollers to reduce their thickness and increase their length. Once the desired dimensions are achieved, the steel coils are then uncoiled and straightened. This process involves feeding the coils through a machine that removes any curvature or deformities, ensuring the strips are completely flat. The straightened coils are then cut into specific lengths to suit the required dimensions of the steel plates. After being cut, the coils undergo another crucial step known as leveling. This process involves passing the strips through a leveling machine, which eliminates any residual stress or warping that may have occurred during the production process. Leveling ensures that the steel plates have a uniform thickness and are free from any distortions, making them suitable for various applications. Once the leveling process is complete, the steel coils are finally transformed into steel plates. These plates can be further processed based on the desired end-use. They may undergo additional treatments such as heat treatment, surface finishing, or coating to enhance their strength, durability, and corrosion resistance. In summary, steel coils are the starting point for the production of steel plates. They undergo several crucial steps, including rolling, uncoiling, straightening, cutting, and leveling, to transform them into flat, uniform steel plates. These plates can then be further processed and customized for a wide range of applications in industries such as construction, automotive, shipbuilding, and manufacturing.

- Q: How are steel coils inspected for surface finish using profilometry?

- Steel coils are inspected for surface finish using profilometry by measuring the surface topography using a profilometer. The profilometer scans the surface of the steel coil and records the deviations from the ideal surface. This data is then used to determine the roughness, waviness, and other surface parameters of the steel coil, providing a quantitative assessment of its surface finish quality.

- Q: How are steel coils used in the production of metal doors and windows?

- Metal doors and windows rely on steel coils as a vital element for their production. These coils, usually crafted from high-grade steel, act as the primary raw material in the manufacturing process. To begin, the uncoiling process is crucial when utilizing steel coils. The coils are unwound and introduced into a machine called a roll former. This machine meticulously molds the steel into the desired shape for the door or window frame. Before entering the roll former, the steel is typically cut to the necessary length. Once the steel has been shaped, it undergoes a series of additional manufacturing processes. These processes may involve creating holes for hardware installation, bending the steel to form specific angles or curves, and welding different sections together to construct a complete frame. The steel coils provide the essential structural integrity and durability required for these processes. Furthermore, steel coils also play a critical role in enhancing the visual appeal of metal doors and windows. They can be coated with various finishes, such as galvanized or powder-coated, to protect against corrosion and enhance the overall appearance of the final product. These coatings not only add an extra layer of durability but also allow for customization to match different architectural styles and design preferences. In conclusion, steel coils serve as the foundational material in the production of metal doors and windows. They are shaped, cut, and processed to create the necessary components for these products. Additionally, steel coils can be coated to improve their durability and aesthetic appeal. Ultimately, these coils significantly contribute to the strength, durability, and overall quality of metal doors and windows.

- Q: How are steel coils used in the production of shipping containers?

- Steel coils are used in the production of shipping containers as they provide the necessary strength and durability required to withstand the demands of transportation and storage. These coils are shaped and welded into the appropriate dimensions to form the walls, roof, and floor of the container. The high tensile strength of steel ensures that the container can withstand heavy loads, impacts, and harsh weather conditions, making it an ideal choice for shipping and protecting goods.

Send your message to us

Hot-Dip Aluzinc Steel Building Roof Walls in Low Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords