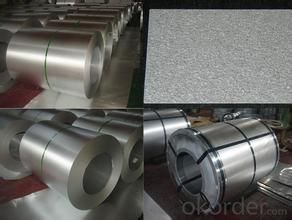

Chinese Cheap Hot-dip Aluzinc Steel Building Roof Walls

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Aluzinc Steel Building Roof Walls

1. Description of the Hot-dip Aluzinc Steel:

Hot-dip aluzinc steel structure is composed of aluminum-zinc alloy, consisting of 55% aluminum, 43% zinc and 2% at 600 ℃ silicon solidification temperature and composition, the entire structure is made of aluminum - iron - silicon - zinc, to form a dense quaternary crystals an alloy.

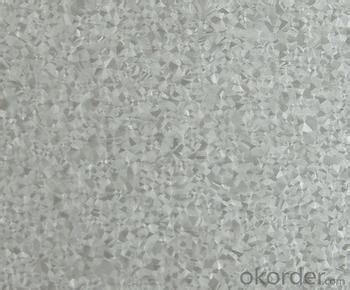

Hot-dip aluzinc steel has many excellent features: strong corrosion resistance, is three times the pure galvanized sheet; zinc surface with beautiful flowers, can be used as a building outside board.

Applications of hot-dip aluzinc steel:

1)Building: roof, walls, garages, soundproof walls, pipes and modular housing.

2)Automotive: muffler, exhaust pipes, wiper accessories, fuel tank, truck boxes, etc.

3)Appliances: refrigerator back, gas stove, air conditioners, microwave oven, LCD frame, 4)CRT-proof band, LED backlight, electrical cabinets, etc.

5)Farm: barn, sheds, silos, piping and other greenhouse.

6)Other: breaking heat insulation cover, heat exchangers, dryers, warm water, etc.

2.Main Features of the Hot-dip Aluzinc Steel:

• Excellent corrosion resistance

• High temperature oxidation resistance

• High hot reflectance

• Good manufacturability

•Beautiful appearance

•Surface coating

•Cost-effective

3.Hot-dip Aluzinc Steel Images

4.Hot-dip Aluzinc Steel Specification

AVAILABLE SPECIFICATION

HOT-DIP ALUZINC STEEL COILS | |

THICKNESS | 0.16mm-3.5mm |

WIDTH | 1250mm MAX |

COATING MASS | 30g/ m2-185 g/ m2 |

SPANGLE | Regular Spangle, Minimized Spangle, Zero Spangle |

SURFACE TREATMENT | Chromated / non-chromated, Oiled / non-oiled, Anti Finger Print |

COIL INNER DIAMETER | 508mm or 610mm |

HOT-DIP ALUZINC STEEL COILS | |||

COMMERCIAL QUALITY | ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 |

STRUCTURE STEEL | SS GRADE 230 SS GRADE 255 SS GRADE 275 SS GRADE 340 SS GRADE 550 | S220GD+AZ S250GD+AZ S280GD+AZ S320GD+AZ S350GD+AZ S550GD+AZ | SGLC400 SGLC440 SGLC490 SGLC570 |

2.5.FAQ of Hot-dip Aluzinc Steel

We have organized several common questions for our clients,may help you sincerely:

1.What advantages does your company have?

Cement : Annual capacity of 400 million tons, No. 1 in the world

Fiberglass: Annual capacity of 1 million tons fiberglass, No. 1 in the world.

Composite Materials — Carbon Fiber: Annual capacity of 10,000 tons PAN precursor and 4,000 tons carbon fiber, No. 1 in China

Composite Materials — Rotor Blade: Annual production capacity of 15,000 pieces, No.1 in China, Top3 worldwide

Glass: CNBM owns about 20 modern float glass product`ion lines, With annual capacity of 10 million square meters glass.

Light Weight Building Materials: Annual capacity of 1.65 billion square meters of gypsum board, No. 1 in the world.

Commercial concrete: Annual capacity of 0.35 billion cubic meters, No. 1 in the world.

Refractory Material: Annual capacity of 40,000 tons casting refractory, No.1 in the world.

2.What advantages do your products have?

Firstly, our base material is of high quality, Their performance is in smooth and flat surface,no edge wave ,good flexibility.

Secondly, high quality zinc ingoats, 97.5% zinc,1.5% silicon,1% others, the same zinc coating measured by metal coating thickness or by zinc weight

Thirdly, high precision: Tolerance strictly according to ASTM or JISG standard even more rigid.

We have full stes of testing equipment(for t best, cupule,chromatism,salt spray resistance, etc) and professional engineers.

- Q: How are steel coils used in the manufacturing of body panels?

- Steel coils are used in the manufacturing of body panels by being fed into a stamping press. The press uses a die to shape and form the steel into the desired body panel shape.

- Q: What are the different grades of steel used in coil manufacturing?

- There are several grades of steel used in coil manufacturing, including but not limited to, low carbon steel (e.g., ASTM A36), high carbon steel (e.g., ASTM A684), stainless steel (e.g., AISI 304), and galvanized steel (e.g., ASTM A653). These grades are chosen based on the desired properties and requirements of the coil being manufactured.

- Q: What is the average width tolerance for steel coils?

- The average width tolerance for steel coils can vary depending on the specific industry and application, but typically it ranges from ±0.005 to ±0.25 inches.

- Q: What are the different types of steel coil coating materials?

- There are several different types of steel coil coating materials that are used in various industries and applications. Some of the most common types include: 1. Polyester: Polyester coil coating materials are known for their durability and resistance to weathering. They are often used in outdoor applications such as roofing and cladding, where they provide excellent protection against fading, chalking, and corrosion. 2. Polyvinylidene Fluoride (PVDF): PVDF coil coating materials are highly resistant to chemicals, UV radiation, and weathering. They are commonly used in architectural applications, where they provide long-lasting color retention and excellent protection against harsh environmental conditions. 3. Polyurethane: Polyurethane coil coating materials offer a high level of flexibility and adhesion, making them ideal for applications that require resistance to abrasion, impact, and bending. They are commonly used in the automotive and appliance industries. 4. Epoxy: Epoxy coil coating materials are known for their excellent adhesion and corrosion resistance. They are often used in industrial applications such as metal furniture, storage tanks, and machinery, where they provide long-lasting protection against chemicals and abrasion. 5. Silicone Modified Polyester (SMP): SMP coil coating materials combine the durability of polyester with the flexibility of silicone. They are commonly used in agricultural and industrial applications, where they provide excellent resistance to chipping, cracking, and peeling. These are just a few examples of the different types of steel coil coating materials available in the market. The choice of coating material depends on the specific requirements of the application, such as durability, weather resistance, chemical resistance, and aesthetics.

- Q: How are steel coils used in the manufacturing of exhaust manifolds?

- Steel coils are used in the manufacturing of exhaust manifolds as they are rolled into specific shapes and sizes to form the primary structure of the manifold. The coils are cut, bent, and welded together to create the required geometry, ensuring the exhaust gases flow smoothly and efficiently from the engine. Additionally, the steel coils provide the necessary strength and durability to withstand high temperatures and the harsh conditions of the exhaust system.

- Q: hello, just wondering if there is such a thing as a stainless steel coating for my aluminum muffler prior to installation. Yes, i suppose you can say that im cutting corners, but my current finances wont allow me to pay full price for a stainless steel one, thnx

- Not as of now maby latter but not now ,

- Q: I saw a 27 sedan and a 27 Pick-up one had wood wheels the other steel, respectively. Witch one was original or were they both original

- Steel wheels were not available on the pickups until 1929. The cars had the options of steel disc or wood spoke wheels in the mid '20's. I'm pretty sure that '27 was the last year the wood wheels were available on passenger cars.

- Q: I need steel toe shoes for a workplace, where can I get them?I live in Surrey,UK.

- steel okorder

- Q: How are steel coils used in the production of structural components?

- Steel coils are used in the production of structural components as they serve as the primary raw material for various manufacturing processes. These coils are typically processed through rolling mills, where they are heated, shaped, and transformed into different structural shapes, such as beams, columns, and plates. The high strength and durability of steel make it an ideal choice for constructing buildings, bridges, and other infrastructure, ensuring the structural integrity and longevity of these components.

- Q: Do you know of any movies that featured the steel drum?

- You okorder /.. If I can find any clips, I'll add them, but I'm sure that many movies in the proper settings (Trinidad, etc.) would have such music and/or show a group or at least a single performer. For example, Cool Running could be a possibility.

Send your message to us

Chinese Cheap Hot-dip Aluzinc Steel Building Roof Walls

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords