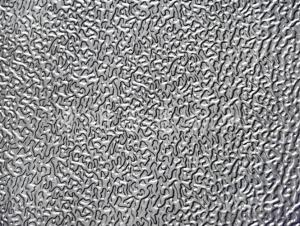

Aluminum Colored Plastic Sheets - Embossed/Coated Alloy Aluminum Coil with Various Patterns

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1 Specifications of Stucco Embossed Coated Aluminium Coil

Alloy | AA1050,AA1060, AA1070, AA1100, AA3003, AA3004, AA3005, AA3105, AA5005, AA5052, AA5754, AA5083, AA8011 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-1.50mm |

Width: | 10mm- 1300mm |

Standard: | GB/T17748-1999, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

2 Full set of process

Professional slitting line,to divide the coil into any width ,with accuracy +-0.02mm;

Professional cutting line,to make sheet with any length;

Embossed line could process aluminum coil with max thickness (1.0mm of A5754H24);

Brushing line,to make the coil brushed as required;

Full-set processing for food-grade aluminum coil and sheet.

3 Sufficient Raw-materials in Stock

To make an shorter lead-time ,lidao hold in stock around 5000tons of aluminum coil mill finishing ,

in alloy A1,A3,or A5 series;with thickness from 2.0mm to 3.0mm width from 1000mm to 2400mm

also approx 2000tons of coated aluminum coil and sheet ,As VIP customers of our suppliers ,we

could always get the raw-materials as soon as possible.

4 Stable and Reliable Quality

Aimed at first-classed market, CNBM Alu. get the raw materials from few excellent supplier like South Western Aluminum, CHALCO, NanShan Aluminum, Suimin and some from Novelis or ALCOA,the coating lacquer are mainly from PPG ,Becker,or Valspar. Aimed at long term cooperation ,Lidao works with professional Quality-inspection term that keeping online 24 hours ,to make completely strick inspection and detailed record on each coil.

5 Our Services

1. Reply you any question within 24 hours.

2. 7 days per week, 24 hours per day available.

3. Sample and more information are avaliable for the client at any time

4. After sale service

- Q: What can I do to remove the paint from the painted aluminum sheet?

- The aluminum need scraping, the car is not easy to enamel paint.Is the aluminum plate with a thickness of more than 0.2mm to 500mm, 200mm width, length less than 16m aluminum material called aluminum plate or aluminum sheet, aluminum is below 0.2mm, 200mm within the width of the row material or bar (of course, with the progress of the large equipment, the width can be 600mm row material also more).

- Q: What unique considerations or prerequisites are necessary when installing aluminum sheets?

- <p>When installing aluminum sheets, there are several special requirements to consider. First, ensure that the surface is clean, dry, and free of any debris to guarantee proper adhesion. Use appropriate fasteners designed for aluminum to prevent corrosion. Measure and cut the sheets accurately to fit the intended area, as aluminum can be prone to warping if not handled correctly. Additionally, consider the environmental conditions, such as temperature and humidity, which can affect the installation process. Always follow the manufacturer's guidelines for installation and safety precautions.</p>

- Q: What is the lifespan of aluminum sheets?

- Various factors, such as the aluminum's grade and thickness, the environmental conditions it encounters, and the level of maintenance it receives, can impact the lifespan of aluminum sheets. Aluminum sheets are renowned for their durability and resistance to corrosion, which contributes to their long lifespan. Aluminum possesses natural resistance against rust and corrosion, making it suitable for a wide array of applications. When given proper care and maintenance, aluminum sheets can endure for numerous years. The construction, automotive, and aerospace industries frequently utilize aluminum sheets due to their lightweight nature and robust properties. In outdoor settings, aluminum sheets can withstand harsh weather conditions, including extreme temperatures, humidity, and exposure to UV radiation. Nevertheless, continuous exposure to certain chemicals or corrosive substances can gradually cause damage. To prolong the lifespan of aluminum sheets, it is crucial to regularly clean and safeguard them. This entails eliminating any dirt or debris that might accumulate on the surface and applying protective coatings or treatments as necessary. In conclusion, while it is challenging to provide an exact timeframe for the lifespan of aluminum sheets, they are generally regarded as a long-lasting material that can withstand the test of time when adequately maintained.

- Q: This question asks for a comparison between aluminum sheets and other roofing materials in terms of their characteristics and performance.

- <p>Aluminum sheets are lightweight and highly durable, offering excellent resistance to corrosion and weathering. They are energy-efficient, reflecting heat and reducing cooling costs. Compared to materials like asphalt shingles, aluminum is more expensive but lasts longer, with a lifespan of 40-50 years. Unlike clay or concrete tiles, aluminum is less prone to breakage and is easier to install. It also doesn't rot or warp like wood, and it's fire-resistant. However, it can be noisy during rain and is less visually appealing than some other materials, but its modern and sleek appearance can be a design advantage.</p>

- Q: What are the different surface finishes available for aluminum sheets?

- Aluminum sheets offer a variety of surface finishes, each with its own unique qualities and aesthetic appeal. Some commonly used finishes include: 1. Mill Finish: This is the most basic finish achieved by leaving the aluminum in its as-rolled state, without any further treatment. It has a smooth and shiny appearance, but may have slight imperfections and is not as durable as other finishes. 2. Anodized Finish: Anodizing is an electrochemical process that creates a protective layer on the surface of the aluminum sheet. This finish enhances corrosion resistance, improves durability, and offers a wide range of color options. Anodized finishes can be matte or glossy. 3. Brushed Finish: By brushing the aluminum sheet with a fine abrasive material, a textured pattern is created. This finish is commonly used for decorative purposes and provides a unique and attractive appearance. 4. Polished Finish: Polishing the aluminum sheet using abrasive materials creates a smooth and reflective surface. This finish is often used for decorative purposes, giving the aluminum a high-end, mirror-like appearance. 5. Embossed Finish: Embossing involves creating raised or recessed patterns on the surface of the aluminum sheet. This finish is commonly used for decorative purposes, adding texture and visual interest to the material. 6. Powder Coated Finish: Powder coating entails applying a dry powder to the aluminum sheet and curing it under heat. This finish provides a durable and weather-resistant coating, available in a wide range of colors and textures. 7. Patterned Finish: Patterned finishes are achieved by imprinting various designs or patterns onto the surface of the aluminum sheet. This finish is often used in architectural applications, adding visual interest to the material. These examples demonstrate the range of surface finishes available for aluminum sheets. The choice of finish depends on the desired appearance, functionality, and application requirements.

- Q: Are 101 aluminum sheets easy to work with in terms of cutting, drilling, and shaping?

- Yes, 101 aluminum sheets are generally easy to work with in terms of cutting, drilling, and shaping. Aluminum is known for its lightweight and malleable properties, making it more manageable compared to other metals. The 101 aluminum alloy specifically offers good formability and weldability, making it suitable for various fabrication processes. When it comes to cutting, aluminum sheets can be easily cut using common tools such as a saw, shears, or even a simple utility knife. Similarly, drilling holes in aluminum sheets is relatively easy and can be done with standard drill bits. Lastly, shaping aluminum sheets can be achieved through bending, folding, or using specialized tools like a brake press. However, it's always important to use appropriate safety measures and equipment when working with any metal, including aluminum.

- Q: What specific coatings or treatments are required for aluminum sheets to enhance their properties or protect them?

- <p>Special coatings or treatments for aluminum sheets may be needed depending on the application. Anodizing is a common treatment that enhances corrosion resistance and wear. For aesthetic purposes, aluminum can be painted or coated with a clear lacquer to maintain its appearance. Protective coatings like powder coating or electroplating can be used to improve durability and resistance to environmental factors. In certain industrial applications, aluminum sheets may be treated with specific coatings to enhance thermal or electrical conductivity. The choice of coating or treatment depends on the specific requirements of the project, such as resistance to weather, chemicals, or mechanical stress.</p>

- Q: What is the typical wear resistance of aluminum sheets?

- The typical wear resistance of aluminum sheets can vary depending on the specific alloy and temper of the sheet. Generally, aluminum sheets have a moderate wear resistance compared to other metals. However, they are not as wear-resistant as materials such as steel or titanium. Aluminum sheets can withstand light to moderate wear and abrasion, making them suitable for applications where they are not subjected to excessive friction or impact. To enhance the wear resistance of aluminum sheets, they can be treated with coatings or surface treatments such as anodizing or painting. Additionally, the thickness and hardness of the aluminum sheet can also affect its wear resistance, with thicker and harder sheets generally offering better resistance to wear.

- Q: There are about 200 holes on the aluminum plate to be machined. There are 100 M12 thread holes, and the rest are 15MM through holes. The tolerance is +0.02. Seeking detailed processing technology, is the first hole or first processing plane, how to control the amount of deformation of the plate, if the milling process can not guarantee flatness, on the grinder, then the 2 surfaces to stay 2MM margin? Are there any 15MM through holes that can be used to maintain tolerances, or do they need to be boring?. Great God advice, the best detail. Aluminum so much done before, no experience, if it does it scrapped.

- The thickness of 2 to 1. fly in place stress to ensure the flatness of the fitter leveling 0.13 more than the Xicheng pay attention to the protection of the appearance of 4 to ensure the flatness of the fabricated fitter. - this thing must not need to be so high, 100 M12 threaded holes, you still press the map to ensure that ah? Such a large plate deformation, 2 millimeters below the hole can be pressed to do

- Q: How does the formability of aluminum sheet vary with different alloys?

- The formability of aluminum sheet can vary significantly with different alloys due to variations in their chemical composition and mechanical properties. Aluminum alloys are typically alloyed with other elements such as copper, manganese, magnesium, and zinc to enhance specific characteristics such as strength, corrosion resistance, and formability. Some aluminum alloys, such as the 1xxx series (pure aluminum) and the 3xxx series (alloyed with manganese), have excellent formability and are often used for deep drawing applications. These alloys can be easily formed into complex shapes without cracking or tearing. On the other hand, alloys with higher strength properties, such as the 2xxx series (alloyed with copper) and the 7xxx series (alloyed with zinc), typically have reduced formability. These alloys are often used in structural applications where strength is crucial, but they may require more careful handling and processing to avoid cracks or other defects during forming. Alloys in the 5xxx series (alloyed with magnesium) generally offer a good balance of formability and strength. They are widely used in various industries, including automotive and aerospace, for their ability to be easily formed into different shapes while providing adequate strength and corrosion resistance. It is important to note that the formability of aluminum sheet is not solely determined by the alloy composition but also influenced by other factors such as the thickness of the sheet, the temperature during forming, and the specific forming process employed (e.g., deep drawing, bending, stretching). These factors can interact with the alloy properties to affect the formability characteristics of aluminum sheet. Therefore, it is essential to carefully select the appropriate alloy and process parameters to achieve the desired formability for specific applications.

Send your message to us

Aluminum Colored Plastic Sheets - Embossed/Coated Alloy Aluminum Coil with Various Patterns

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords