Geotextile Design Non-Woven Filter Fabric Geotextile for Railway Applications from CNBM China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Made from polyester(PET)short fiber by nonwoven needle punched manufacturing process, it has isolation, filteation,drainage, reinforcement, protection and maintenance etc. function.

Specification:

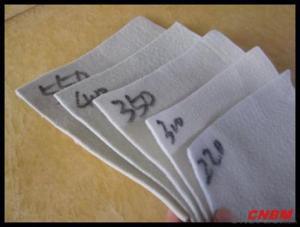

1.Unit weight 100g/sqm,150g/sqm,200g/sqm,250g/sqm,300g/sqm,350g/sqm,400g/sqm,450g/sqm,500g/sqm,600g/sqm,800g/sqm

2.Width

1m-8m

3.Length:

Per clients' request

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in stormwater detention systems?

- Yes, geotextiles can be used in stormwater detention systems. Geotextiles are permeable fabrics that can help control erosion and filter sediment in stormwater runoff. In detention systems, they can be used as a barrier to separate soil layers, enhance filtration, and improve overall system performance by preventing clogging and promoting efficient water flow.

- Q: Why do you want to set up geotextiles around the bottom and bottom of the ditch? What role? Which predecessors help me explain.

- Why do you want to set up geotextiles around the bottom and bottom of the ditch? What role? Which predecessors help me explain.

- Q: What are the uses of acupuncture geotextiles?

- I specialize in producing geotextile materials

- Q: What are the different geotextile manufacturing processes?

- There are several different geotextile manufacturing processes, including weaving, knitting, and nonwoven methods. Weaving involves interlacing yarns in a crisscross pattern, creating a strong and durable material. Knitting involves interlocking loops of yarn, resulting in a flexible and stretchable fabric. Nonwoven processes involve bonding fibers together using heat, chemicals, or mechanical methods, producing a lightweight and permeable textile. Each manufacturing process has its own advantages and is used for different applications depending on the desired characteristics of the geotextile.

- Q: What are the key considerations for geotextile installation in cold climates?

- There are several key considerations for geotextile installation in cold climates. First, it is important to choose a geotextile material that is specifically designed for cold weather conditions. This ensures that the material will not become brittle or easily damaged in freezing temperatures. Additionally, proper site preparation is crucial, including removing snow and ice from the installation area to ensure a stable base for the geotextile. It is also important to properly anchor the geotextile to prevent shifting or movement due to freeze-thaw cycles. Overall, careful selection of materials and proper installation techniques are essential for successful geotextile installation in cold climates.

- Q: How are geotextiles manufactured?

- Geotextiles are typically manufactured using a process called needle punching. This involves mechanically interlocking synthetic fibers together to create a strong and durable fabric. The fibers are first carded, meaning they are aligned and separated, before being fed through a machine that punches them with barbed needles. These barbs entangle and interlock the fibers, creating a stable fabric structure. Further processes such as heat setting, calendaring, and coating may be applied to enhance the geotextile's properties, such as increasing its resistance to UV degradation or improving its filtration capabilities.

- Q: Are geotextiles suitable for use in high-temperature environments?

- No, geotextiles are not suitable for use in high-temperature environments.

- Q: Can geotextiles be used in erosion control blankets?

- Yes, geotextiles can be used in erosion control blankets. Geotextiles, which are permeable fabrics, are commonly used in erosion control blankets to prevent soil erosion by stabilizing the soil, reducing water velocity, and promoting vegetation growth. These blankets are typically made of biodegradable materials and are designed to provide temporary erosion control until vegetation is established.

- Q: Such as the title, the drawings are written on the weaving geotextile, the list is written on the blended geotextile cloth laying / 120g / m2 weaving geotextile, who can tell ah !!!!!!!!!! Urgent more

- Or geotextile ah

- Q: Do geotextiles affect soil pH levels?

- No, geotextiles do not affect soil pH levels.

Send your message to us

Geotextile Design Non-Woven Filter Fabric Geotextile for Railway Applications from CNBM China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords