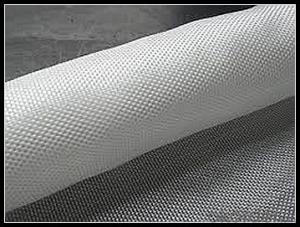

Geotextil Ecuador Non-Woven Fabric Geotextile Low Price for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Features

1.Abrasion resistance,flexibility

2.Safe and easy for construction

3.Excellent drainage performance

4.High strength, anti-aging,anti-acid and alkali

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

- Q: The difference between the geotextile and the geotextile

- I professional production geotextile geomembrane and other geotechnical materials, a professional construction of the welding team, wish smooth

- Q: Geotextile thinnest how many grams

- 80-100g, I am specializing in the production of geotextile geomembrane, wish smooth

- Q: What are the different types of geotextile installation equipment?

- Some common types of geotextile installation equipment include geotextile rollers, geotextile stitchers, geotextile spreaders, geotextile staplers, and geotextile tensioners. These tools are used to efficiently and effectively install geotextiles in various applications such as erosion control, soil stabilization, and drainage systems.

- Q: Filter geotextile, permeable geotextile, seepage geotextile What is the difference?

- The above three products are a product. But is divided into polypropylene staple acupuncture geotextile, polyester staple acupuncture geotextile, filament geotextile. Three categories. Play a major role is good permeability, filtration, isolation performance, construction convenience.

- Q: Can geotextiles be used in flood protection projects?

- Yes, geotextiles can be used in flood protection projects. Geotextiles are often used as a cost-effective and sustainable solution for erosion control, sediment filtration, and stabilization of soil in flood-prone areas. They can be used in various applications such as riverbank protection, levee reinforcement, and shoreline stabilization, helping to reduce the impact of floodwaters and prevent soil erosion.

- Q: Are geotextiles biodegradable?

- No, geotextiles are not biodegradable.

- Q: How are geotextiles recycled?

- Geotextiles can be recycled through a process called mechanical recycling. This involves collecting used geotextiles, cleaning them, and breaking them down into smaller fibers or pellets. These recycled materials can then be used to manufacture new geotextiles or other products, reducing the need for raw materials and minimizing waste.

- Q: Can geotextiles be used in waste storage facility applications?

- Yes, geotextiles can be used in waste storage facility applications. Geotextiles are commonly used in these facilities to provide erosion control, filtration, and separation of different waste materials. They help to enhance the stability and performance of the storage facility by preventing soil erosion and promoting proper drainage. Additionally, geotextiles can also be used to cover and contain waste materials, preventing any potential contamination or leaching into the surrounding environment.

- Q: What are the different geotextile installation techniques in filtration?

- Some of the different geotextile installation techniques in filtration include direct placement, wrap and trench, and sand bag placement. Direct placement involves placing the geotextile directly on the soil surface, while wrap and trench involves wrapping the geotextile around a soil layer or pipe and placing it in a trench. Sand bag placement involves constructing sand bags filled with soil and placing them against the geotextile to hold it in place. These techniques help to ensure proper filtration and prevent soil erosion.

- Q: How do geotextiles help in the separation of materials?

- Geotextiles help in the separation of materials by acting as a barrier between different layers of soil or other materials. They prevent the mixing or migration of particles, such as preventing fine soil from mixing with coarse aggregate in road construction, ensuring proper drainage and stability.

Send your message to us

Geotextil Ecuador Non-Woven Fabric Geotextile Low Price for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords