Tipos De Geotextil:Short Fabric Non-Woven Geotextile Fabric for Road Construction with Highest Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

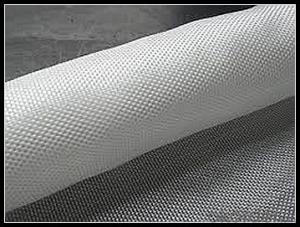

High tension.Because it's made of Plastic flat yarn,it can keep enough tenacity and stretching.

2. Non-corrosive.It can be non-corrosive for long time in soil and water with different PH value.

3. Good Water Permeability.There is space between flat yarn,so it has good water permeability.

4. Good antimicrobic. For organisms,there will be no worm-holes.

5. Easy construction.Because of light material,soft,it's easy for transportation,spreading out and construction.

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

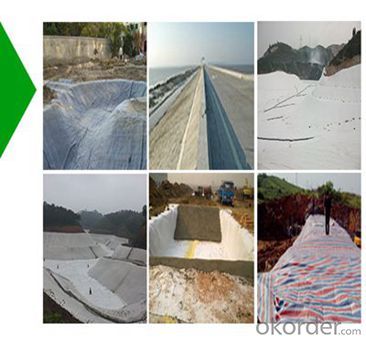

- Q: What are the different applications of geotextiles in agriculture?

- Geotextiles have various applications in agriculture, including erosion control, soil stabilization, weed suppression, moisture retention, and filtration. They are used as ground covers to prevent soil erosion caused by wind or water, providing stability to slopes and embankments. Geotextiles also help in retaining moisture in the soil, reducing the need for irrigation. Additionally, they act as a barrier to control weed growth, reducing the competition for nutrients and water. Furthermore, geotextiles are employed for filtration purposes, allowing water to pass through while preventing the loss of fine particles. Overall, geotextiles play a crucial role in enhancing agricultural practices and promoting sustainable farming.

- Q: How do geotextiles affect plant growth?

- Geotextiles can positively impact plant growth by providing a stable environment for roots, preventing soil erosion, and promoting moisture retention. Additionally, they control weed growth, regulate soil temperatures, and enhance nutrient availability, ultimately leading to healthier and more productive plants.

- Q: Geotextile above allowed to plant grass?

- Geotextile above the grass To protect the slope, then the direct use of three-dimensional vegetation network can not Well! User name is the manufacturer phone! The The

- Q: How do geotextiles help in preventing weed growth?

- Geotextiles act as a physical barrier that prevents weed seeds from accessing sunlight and nutrients, inhibiting their growth and establishment. They also help in reducing soil erosion and maintaining the integrity of landscaping projects.

- Q: Can geotextiles be used for reinforcement of railway embankments?

- Yes, geotextiles can be used for reinforcement of railway embankments. Geotextiles are commonly used in civil engineering projects for their ability to provide separation, filtration, and reinforcement functions. When used in railway embankments, geotextiles help improve the stability and strength of the embankment by preventing the mixing of different soil layers, reducing soil erosion, and distributing load more evenly. Overall, geotextiles are an effective solution for reinforcing railway embankments and enhancing their long-term performance.

- Q: How do geotextiles improve the performance of shorelines?

- Geotextiles improve the performance of shorelines by providing erosion control, stabilizing the soil, and enhancing drainage. They act as a barrier that prevents soil erosion and helps to retain sediment, reducing the impact of waves and currents on the shoreline. Geotextiles also improve the stability of the soil by distributing the load and reducing the effects of settlement. Additionally, they enhance drainage by allowing water to pass through, preventing the buildup of hydrostatic pressure that can further damage the shoreline.

- Q: What is the waterproof selection of artificial lake? How to build?

- There are many features ah

- Q: What are the advantages of using geotextiles in green space development?

- There are several advantages of using geotextiles in green space development. Firstly, geotextiles help in soil stabilization by preventing erosion, which is crucial for the long-term sustainability of green spaces. Secondly, they improve water drainage and filtration, allowing for better moisture retention and reducing the risk of waterlogging. Additionally, geotextiles act as a barrier to weed growth, reducing the need for herbicides and manual maintenance. Lastly, they provide reinforcement and support to the soil, increasing its load-bearing capacity and enabling the development of structures like pathways and driveways. Overall, the use of geotextiles in green space development enhances the durability, functionality, and aesthetic appeal of these areas.

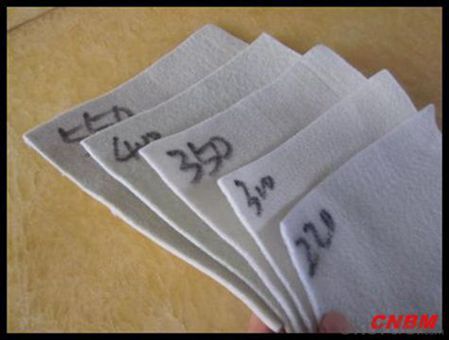

- Q: What are the key factors affecting the tensile strength of geotextiles?

- The key factors affecting the tensile strength of geotextiles include the type and quality of the materials used, the manufacturing process, the thickness and weight of the geotextile, the orientation and arrangement of the fibers, as well as environmental factors such as exposure to sunlight, moisture, and temperature.

- Q: How do geotextiles help with reinforcement of geogrid reinforced soil slopes?

- Geotextiles help with the reinforcement of geogrid reinforced soil slopes by acting as a separator and filter between the soil and the geogrid. They prevent the soil particles from passing through the geogrid openings, maintaining its stability and preventing the loss of soil material. Additionally, geotextiles distribute the load and stress evenly across the geogrid, enhancing its load-bearing capacity and overall performance in reinforcing the soil slope.

Send your message to us

Tipos De Geotextil:Short Fabric Non-Woven Geotextile Fabric for Road Construction with Highest Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords