Geotextile Class 2 Nonwoven Fabric Geotextile Fabric Price Road Building Constructive Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

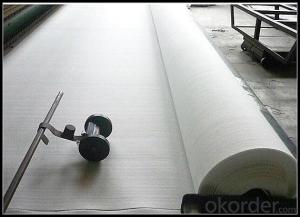

The needle-punched non woven geotextile is produced from polyester or polypropylene fiber by differentequipment and technology to get different thickness.

The main function is filtration, drainage, reinforcement. It has good impermeability and resistance to deformationNonwoven Technicneedle punchedGradeA gradeThicknessany thicknessColorsvarious colors available in stock all year round, see the color swatch, any colour can be made-to-orderStandard Width2m, 4m, 6.5m, 8.5mFeature/ Special Treatmenthigh tensile strength, excellent filtering ability, water pass through, breathable, biodegradable, recyclable, eco-friendly, nontoxic; special treatment: embossing, printing, anti-static, fire(flame) retardant, anti-ultraviolet, heat resistent, softerApplicationsGeotextiles (meet the international standard, used in water conservancy engineering, highway tunnel construction, ect), filter/packing material, sole material of shoes, base material of breeding and planting, bedding and furniture inner material,toys, leather and shoe fabric, planting bag, medical wound pad, cleaning wipes, etc.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

pecifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Geotextile manufacturers rely on what to do a hundred years do not rot geotextile

- Because geotextile raw materials are chemical fiber. Huazhi geotextile material answer

- Q: What kind of geotextiles are used in highway geotextiles?

- Highway geotextile general use Hongxiang new material filament geotextile, to overcome the cracks and so on the road defects.

- Q: Do you have a drainage board and a geotextile?

- How many dishes? Drainage board and geotextile a square need about 15 yuan cost, their trade-off

- Q: What are the advantages of using geotextiles in hydraulic applications?

- Geotextiles offer several advantages in hydraulic applications. Firstly, they provide excellent filtration properties, allowing water to pass through while retaining soil particles. This helps in preventing soil erosion and maintaining the stability of hydraulic structures. Secondly, geotextiles act as a barrier against soil migration, reducing the likelihood of clogging or blockage in drainage systems. Additionally, they enhance the overall durability and longevity of hydraulic structures by distributing loads and reducing stress on underlying soils. Lastly, geotextiles are lightweight and easy to install, making them a cost-effective solution for various hydraulic projects.

- Q: River design design depth of 1 meter, 100 meters wide surface, requiring geotextile cloth two films. How many grams are appropriate? Bao Bao package material per square meter open to move to cut the amount of taxation Bao Bao Bao how much money first thank you master, urgent use. More

- Collar - Xiang, composite geomembrane, geotextile, a variety of specifications

- Q: What is the latest price of geotextile?

- Ask the geotextile price is too general, because the standard too much. Short wire, filament, polyester; non-standard, GB and so on. Ton price is generally between 4900-7500 yuan / ton, but the weight <200g, an increase of 100 yuan / ton; weight> 800g, an increase of 500 yuan / ton.

- Q: Geotextile business how to run

- Geotextile as a geotextile material, engineering applications have been very popular, the market competition is also very intense. Profits have been very low Bulk geotextile transactions are mainly ordered in the form of tender, so please pay attention to bidding information, I wish you success.

- Q: How are geotextiles used in shoreline protection?

- Geotextiles are used in shoreline protection to prevent erosion by stabilizing the soil and reducing wave energy. They are placed along the shoreline to act as a barrier, preventing sediment from being washed away and providing a stable foundation for vegetation to grow. Additionally, geotextiles can be used to filter water and trap sediment, improving water quality and protecting the shoreline from further degradation.

- Q: What are the design considerations for geotextile-reinforced slopes?

- Some key design considerations for geotextile-reinforced slopes include selecting the appropriate type and strength of geotextile, considering the slope angle and height, evaluating the soil conditions and stability, determining the required length and spacing of reinforcement layers, ensuring proper installation and quality control, and accounting for factors such as water drainage and vegetation establishment. Additionally, the design should consider the long-term durability and maintenance requirements of the reinforced slope.

- Q: What are the different factors to consider for geotextile selection in landfill applications?

- There are several factors to consider when selecting geotextiles for landfill applications. These include the type and composition of waste being disposed, the required strength and durability of the geotextile, its resistance to chemical and biological degradation, its ability to allow for proper water drainage, and its compatibility with the site conditions and construction methods. Additionally, factors such as cost, availability, and regulatory requirements should also be taken into account during the selection process.

Send your message to us

Geotextile Class 2 Nonwoven Fabric Geotextile Fabric Price Road Building Constructive Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords