Aluminum Foil Faced Insulated Rubber Sheet Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Flexible Rubber Plastic Insulation Material Product Description

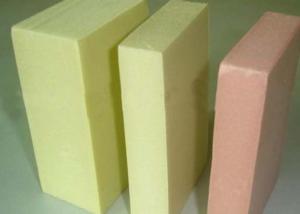

Rubber plastic is a high quality heat-insulating and heat-preservation material which use but yronitrile rubber and polyvinyl chloride(NBR,PVC) as main raw materials. The production process includes mixing, tensing and continuous extruding , heating and foaming.

2.Main Features of Rubber Plastic

-Lower heat-conductivity-Higher fire-blocking performance-Damp-proof and Water-proof-Softness-Neat and -Easy to install easy handing and storage-Good flexibility and tenacity

3.Rubber Plastic Images

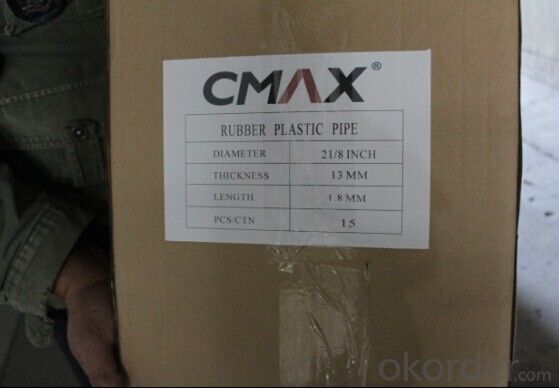

4.Rubber Plastic Specification --Rubber Plastic Sheet

Density(kg/m3) | 40-90 | ||||

Thickness(mm) | 10 mm | 15 mm | 20 mm | 25 mm | 30 mm |

Length (m) | 20 | 20 | 10 | 10 | 10 |

Width (m) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

5.FAQ

①How about your company?A world class manufacturer & supplier of HVAC materials,is one of the large-scale professional investment building materials production bases in China.

②How to guarantee the quality of the products?We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase? In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Is it safe and practical to use black fiberglass tissue as a material for bedding or curtains?

- <p>Black fiberglass tissue is not recommended for bedding or curtains due to its composition and properties. Fiberglass is a type of glass wool that can be irritating to the skin and respiratory system. It is typically used for insulation and not for direct contact with the skin or as a decorative material. For bedding and curtains, it's better to use materials that are soft, breathable, and safe for human contact, such as cotton, linen, or polyester blends.</p>

- Q: This question asks for a comparison between black fiberglass tissue and other types of insulation materials, highlighting their differences.

- <p>Black fiberglass tissue is a type of insulation material known for its high tensile strength and resistance to heat and corrosion. It is made from fine glass fibers and is often coated with a black resin to enhance its UV resistance and durability. Unlike other insulation materials such as cellulose, mineral wool, or polyisocyanurate foam, black fiberglass tissue is lightweight, flexible, and can be easily cut to fit various shapes. It also has excellent thermal and acoustic insulating properties. However, it may not provide the same level of fire resistance as some other materials, and it can cause skin and respiratory irritation if not handled properly with protective gear.</p>

- Q: Now what is the latest color steel sandwich board? such as: Foam, stretches, glass wool

- Foam is the mainly material, now with the increase of rock wool, the rock wool can be fireproofing and sound absorption, it may also lay glass wool in the interior of color steel?plate and the function is sound absorption and thermal insulation.

- Q: Is it safe to use aluminum foil with a reflective side for storing food?

- <p>Yes, aluminum foil facing can be used for food storage. It is commonly used to wrap, cover, or store food in the refrigerator or freezer. The reflective side of aluminum foil is safe for food contact as it is made of a food-grade material. However, it's important to ensure the foil is clean and free from any damage or sharp edges that could puncture other food packaging. It's also advisable to avoid using it in direct contact with acidic or alkaline foods, as this can cause the foil to corrode and potentially release aluminum into the food.</p>

- Q: Is it safe to use aluminum foil with a recycled material facing when baking food?

- <p>Using recycled aluminum foil facing for baking is generally safe, as long as it meets food-grade standards and is specifically designed for cooking applications. Recycled aluminum foil used in cooking should be free from harmful chemicals and should not release any toxic substances when heated. However, it's crucial to check the packaging to ensure it is labeled as 'oven-safe' and 'food-grade.' Avoid using foil that is not intended for cooking, as it may contain additives or coatings that are not safe at high temperatures. Always follow the manufacturer's guidelines for safe use.</p>

- Q: Is it possible to use black fiberglass tissue as an insulating material for the roofs of residential homes?

- <p>Yes, black fiberglass tissue can be used for roof insulation in residential homes. It is a type of insulation material that provides thermal resistance, helping to reduce heat transfer and maintain a comfortable indoor temperature. Black fiberglass is also known for its durability and resistance to moisture, which can be beneficial in various climates. However, it's important to note that proper installation and ventilation are crucial for its effectiveness and to prevent any potential health risks associated with fiberglass.</p>

- Q: Is it appropriate to use black fiberglass tape for insulation purposes?

- <p>Black fiberglass tape can be used for insulation purposes, particularly for sealing and reinforcing insulation materials. It is often used to wrap around pipes, ducts, and other surfaces to provide an additional layer of protection against heat loss or cold. However, it's important to note that fiberglass tape is not a primary insulating material but rather a supplementary one. It's also crucial to ensure that the tape is suitable for the temperature range of the application and that it's properly secured to prevent air and moisture infiltration.</p>

- Q: Who has the building part of the building, the decorative parts inside the metal decoration on the staircase handrail aspects of the content.

- 5mm; the other diameter 51mm, Wall thickness of 3mm; according to its location and role of different, can be divided into pole, horizontal bar, sweeping pole and so on Fastener: fastener is the pipe pipe trace pipe boiling degree of sand between the spine and the pipe between the connection, in three forms, namely right angle fasteners, rotating fasteners, butt fasteners fasteners: for two The connection of the vertically intersecting steel pipe, which relies on the friction between the fastener and the steel pipe, carries the load Rotating fastener: Used for connection of two angles at any angle Butt fasteners: for two steel pipe docking long connection Base and pad: is set up at the bottom of the pole seat, pay attention to the difference between the base and the pad, the base is generally welded with steel and steel pipe, the base is generally placed on top of the pad, and the pad can be wood It can also be steel Scaffolding (see illustration below), safety net (no explanation, this is very simple) Here are some key difficult to understand the term The main node: refers to the pole, vertical and horizontal horizontal bar at the junction of the three-point junction Sweep bar: the horizontal bar that is close to the ground and connects the base of the pole Vertical distance (or cross): vertical distance of the scaffolding pole Pole step (or step): the distance between the upper and lower horizontal axis See

- Q: This question asks about the various types of black fiberglass tissue that can be found in the market.

- <p>There are several types of black fiberglass tissue available in the market, each with distinct properties and applications. These include woven roving, chopped strand mat, continuous filament mat, surfacing mat, and stitch-bonded mat. Woven roving is used for high strength applications, chopped strand mat for general reinforcement, continuous filament mat for smooth surfaces, surfacing mat for providing a smooth finish, and stitch-bonded mat for added dimensional stability. Each type varies in weave, density, and fiber length, catering to different industrial needs.</p>

- Q: Is it possible to use aluminum foil with a reflective side for baking bread?

- <p>Yes, aluminum foil facing can be used for baking bread, but with some considerations. The reflective side of aluminum foil can help retain heat and moisture, which is beneficial for bread baking. However, it's important to avoid direct contact between the foil and the bread to prevent sticking. You can use the foil to line the baking sheet or create a tent over the bread to trap steam, which contributes to a better crust and texture. Always monitor the bread closely when using foil to prevent over-browning or burning.</p>

Send your message to us

Aluminum Foil Faced Insulated Rubber Sheet Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords