Flexible Elastomeric Thermal Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

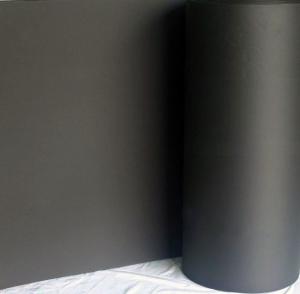

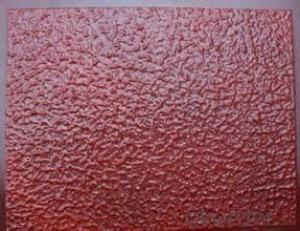

RUBBER PLASTIC Flexible Elastomeric Thermal Insulation

rubber plastic isa high quality heat-insulating and heat-preservation material which use butyronitrile rubber and polyvinychloride(NBR,PVC) as main raw materials.

The productionprocess includes mixing, tensing and continuous extruding , heating andfoaming, cooling and cutting.

FEATURES

Lower heat-conductivity

Higher fire-blockingperformance

Damp-proof andWater-proof

Softness

Neat and

Easy to installeasy handing and storage

Good flexibilityand tenacity

RUBBER PLASTIC SHEET

Standard Size

Density(kg/m3) | 40-90 | ||||

Thickness(mm) | 10 mm | 15 mm | 20 mm | 25 mm | 30 mm |

Length (m) | 20 | 20 | 10 | 10 | 10 |

Width (m) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

Remark: Othersized are available upon request. Other colors are available at customers request.

Application

rubber plastic arewidely used in sound isolation of wall planking, sound absorption in air ducts,and sound absorbing decorations in entertainment spaces. It can also be usedfor shock resistance and pressure relief in instruments and equipment.

TechnicalParameters

Item | Specification | Standard |

Density(kg/m3) | 40-90 | GB/T 6343 |

Temperature(℃) | -40~110 | GB/T 17794 |

Flammability | Class B | GB/T 8624-2006 |

Class 0 | BS 476Part7∝Part6 | |

Oxygen index (%) | ≥40 | GB/T 2406 |

SDR | ≤65 | GB/T8627-1999 |

Conductivity factor Average temperature | ≤0.031 | GB/T 10294 |

Water vapor permeability (%) | ≥1.0x104 | GB/T 17146-1997 |

≤1.96x 10-11 | ||

Water absorption ratio in vacuum (%) | ≤10 | GB/T 17794-2008 |

Dimension stability(N/cm) | ≤10 | GB/T 8811 |

Crack resistance | ≥2.5 | GB/T 10808 |

Compression resilience ratio (%) | ≥70 | GB/T 6669 |

Anti-ozone | No cracking | GB/T 7762 |

Ageing-resistance | Slightly crumpling, no cracks no pin holes, not deforming | GB/T 16259 |

Packaging,

Product is packedin cartoon.

RUBBER PLASTIC PIPE

Productintroduction

rubber plastic ismainly applicable to heat insulation of central air-conditioner system,refrigerator room and pipes of all kinds of refrigeration equipment and heatingequipment.

Standard Size

Copper tube OD inch | Seamless tube OD mm | Galvanized tube DN | ID mm | 9mm Nominal thickness | 15mm Nominal thickness | 20mm Nominal thickness | 25mm Nominal thickness | 30mm Nominal thickness | |||||

mm×mm | piece | mm×mm | piece | mm×mm | piece | mm×mm | piece | mm×mm | piece | ||||

1/4 |

|

| 6 | 6×9 | 180 |

|

|

|

|

|

|

|

|

3/8 |

| 6 | 10 | 10×9 | 140 | 10×15 | 80 | 10×20 | 70 |

|

|

|

|

1/2 |

|

| 13 | 13×9 | 120 | 13×15 | 80 | 13×20 | 50 |

|

|

|

|

5/8 | 14 | 8 | 16 | 16×9 | 100 | 16×15 | 60 | 16×20 | 50 |

|

|

|

|

3/4 |

|

| 19 | 19×9 | 100 | 19×15 | 60 | 19×20 | 40 |

|

|

|

|

7/8 | 22 | 15 | 22 | 22×9 | 100 | 22×15 | 60 | 22×20 | 40 | 22×25 | 30 | 22×30 | 25 |

1 | 25 |

| 25 | 25×9 | 80 | 25×15 | 60 | 25×20 | 30 | 25×25 | 25 | 25×30 | 25 |

1 1/8 | 28 | 20 | 28 | 28×9 | 60 | 28×15 | 50 | 28×20 | 30 | 28×25 | 25 | 28×30 | 20 |

1 1/4 | 32 |

| 32 | 32×9 | 60 |

|

|

|

|

|

|

|

|

1 1/4 | 32 |

| 34 |

|

| 34×15 | 40 | 34×20 | 30 | 34×25 | 25 | 34×30 | 20 |

1 3/8 |

| 25 | 35 | 35×9 | 60 |

|

|

|

|

|

|

|

|

1 1/2 |

|

|

| 38×9 | 50 |

|

|

|

|

|

|

|

|

1 5/8 |

| 25 | 42 | 42×9 | 50 |

|

|

|

|

|

|

|

|

1 5/8 |

| 32 | 43 | 43×9 | 50 | 43×15 | 30 | 43×20 | 25 | 43×25 | 20 | 43×30 | 15 |

1 7/8 |

| 40 | 48 | 48×9 | 50 | 48×15 | 30 | 48×20 | 25 | 48×25 | 20 | 48×30 | 15 |

2 1/8 |

|

| 54 | 54×9 | 50 |

|

|

|

|

|

|

|

|

2 3/8 |

| 50 | 60 | 60×9 | 50 | 60×15 | 30 | 60×20 | 20 | 60×25 | 15 | 60×30 | 15 |

| 76 | 70 | 76 |

|

| 76×15 | 25 | 76×20 | 15 | 76×25 | 15 | 76×30 | 10 |

| 89 | 80 | 89 |

|

|

|

| 89×20 | 15 | 89×25 | 15 | 89×30 | 10 |

| 108 |

| 108 |

|

|

|

| 108×20 | 15 | 108×25 | 10 | 108×30 | 10 |

- Q: This question asks for instructions on how to clean aluminum foil facing after it has been used in cooking or baking.

- <p>To clean aluminum foil facing after use, first let it cool down to avoid burns. Then, gently scrape off any food residue with a spatula or the edge of a knife. For stubborn stains, mix a solution of warm water and dish soap, and wipe the surface with a soft cloth or sponge. Rinse with clean water and dry thoroughly. For baked-on food, you can use a plastic scraper or an old toothbrush to gently remove it. Avoid using abrasive materials that could scratch the surface. Regular cleaning will help maintain the integrity and appearance of your aluminum foil facing.</p>

- Q: What are the safety regulations or guidelines that aluminum foil facing must adhere to?

- <p>Safety standards for aluminum foil facing are crucial to ensure the product's safety and effectiveness. These standards typically include requirements for material composition, thickness, and bonding strength to ensure the foil's durability and resistance to tearing. Additionally, there are guidelines for the foil's reflectivity and heat resistance, which are important for its performance in various applications. Compliance with these standards is often verified through testing and certification processes, ensuring that aluminum foil facing products meet the necessary quality and safety benchmarks before they reach the market.</p>

- Q: This question asks for methods to clean aluminum foil that has excess oil on it after cooking or food storage.

- <p>To remove excess oil from aluminum foil facing after cooking or food storage, you can follow these steps: 1. Allow the foil to cool down to avoid burns. 2. Use a paper towel to blot and absorb the excess oil. 3. For stubborn oil, you can wipe the foil with a damp cloth or sponge with a mild dish soap. 4. Rinse the foil thoroughly with warm water to remove any soap residue. 5. Dry the foil with a clean towel or let it air dry. If the oil is extremely stubborn, consider using a gentle scrubber or baking soda paste to help remove it. Always check the foil for any damage or wear before reusing it.</p>

- Q: Describe the optimal method for utilizing aluminum foil facing in cooking.

- <p>The best way to use aluminum foil facing for cooking is to preheat your oven and ensure the foil is shiny side up to reflect heat. For baking, create a tent with the foil to protect delicate foods from direct heat, which can prevent burning. When roasting, use foil to wrap foods like fish or vegetables to steam them, enhancing flavor and moisture retention. For grilling, use foil to create packets to cook foods indirectly or to line the grill to prevent food from sticking. Always handle with care to avoid tearing and ensure even heat distribution.</p>

- Q: Can the shiny side of aluminum foil be utilized as a reflective surface?

- <p>Yes, aluminum foil facing can be used as a reflector. Aluminum foil has a highly reflective surface, which makes it suitable for reflecting light and heat. The shiny side of the foil is particularly effective due to its smooth and polished finish. It is commonly used in various applications such as cooking, gardening, and DIY projects to reflect heat or light. However, it's not as efficient as specialized reflective materials like mirrors or aluminum-coated fabrics, and it can degrade over time with exposure to elements.</p>

- Q: What are the materials and elements that make up the aluminum foil facing?

- <p>Aluminum foil facing is primarily composed of aluminum, which is a lightweight, malleable, and ductile metal with the symbol Al and atomic number 13. It is commonly used in construction, packaging, and cooking due to its excellent thermal and electrical conductivity, as well as its resistance to corrosion. The aluminum used for foil is typically of high purity, but it may also contain trace amounts of other elements to enhance certain properties, such as copper to improve strength or magnesium to increase resistance to corrosion. The facing can also have a protective layer or coating to prevent oxidation or to enhance its performance in specific applications.</p>

- Q: This question asks for the most effective methods to utilize aluminum foil when preparing food for freezing or frying, specifically focusing on the aluminum foil facing.

- <p>Aluminum foil facing is best used for preparing food for freezing or frying by ensuring even heat distribution and maintaining food's moisture. For freezing, line your baking sheet with aluminum foil facing down to prevent sticking and make removal easier. When freezing individual portions, wrap them tightly in foil to protect their shape. For frying, use foil to create a barrier between the food and direct heat, which can help in even cooking. Always make sure the foil is shiny side out for better heat reflection and椋熷搧瀹夊叏. Remember to avoid overheating as aluminum foil can melt at high temperatures.</p>

- Q: This question asks whether glass or ceramic containers are preferable for storing food over plastic or metal containers.

- <p>Glass and ceramic containers are often considered better for storing food due to their non-porous nature, which prevents the absorption of flavors and potential leaching of chemicals. Glass is generally safe for storing both acidic and alkaline foods, while ceramic containers should be checked for lead-based glazes, especially for acidic foods. Plastic containers can leach chemicals over time, and metal containers may react with certain foods, affecting taste or safety. However, the choice also depends on factors like the type of food, storage duration, and personal preference.</p>

- Q: This question asks for a comparison between aluminum foil facing and other types of metal foil facing, focusing on their differences.

- <p>Aluminum foil facing is distinct from other metal foil facings due to its unique properties. It is lightweight, highly reflective, and offers excellent heat resistance. It's also non-toxic and has good barrier properties against oxygen and moisture, making it ideal for food packaging and insulation. Other metal foils, such as copper or stainless steel, may have different thermal or electrical conductivity properties, and are often heavier and less flexible. Copper, for instance, has higher electrical conductivity but is less common in foil applications due to cost and weight. Stainless steel foils are more durable and corrosion-resistant but are not as reflective or lightweight as aluminum. Each type of metal foil has specific applications based on its unique characteristics.</p>

- Q: Is it safe to use aluminum foil facing inside a microwave oven?

- <p>No, it is not safe to use aluminum foil facing in the microwave oven. Aluminum foil can cause sparks and potentially start a fire due to the reflective nature of the metal. It can also damage the oven's interior. Always use microwave-safe materials and avoid metal when cooking in a microwave.</p>

Send your message to us

Flexible Elastomeric Thermal Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords