Neoloy Geocells Superior Quality Fiberglass Geogrid with Asphalt

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

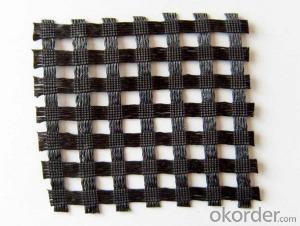

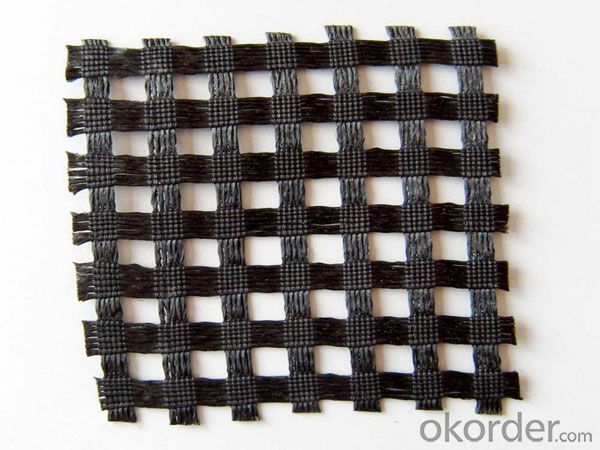

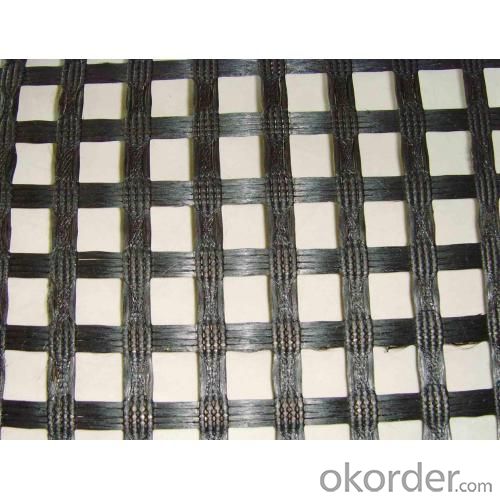

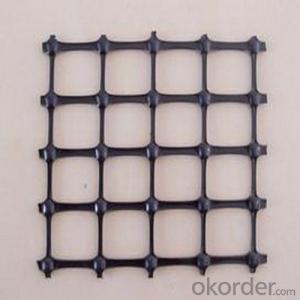

Structure of Quality Fiberglass Geogrid:

Bitumen Coated Fiberglass Geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed.This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after surface covering own the favorable property of alkali resistance and aging resistance.

Main Features of Quality Fiberglass Geogrid:

fiberglass geogrid for soil reinforcement

Reinforcement of the surface of road and bridge.

High tensile strength, low elongation

Dyke reinforcement on soft ground for stress evenness,sedimentation adjustment,increase of stability and loading capacity of fundus;

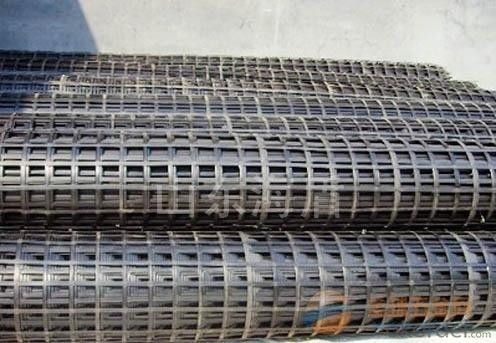

Fiberglass Geogrid Images

Fiberglass Geogrid Specification

Polyester Geogrid GGF80 Technical Specification | |||

Property | Test Method | Unit | Index |

Wide Width Tensile Strength | |||

MD | KN/M | ≥80 | |

CMD | KN/M | ≥80 | |

Elongation At Break | ≤4 | ||

Grid | MM | 25.4×25.4 | |

Width | M | 1~6 | |

Packaging | Details | ||

Roll Dimensions(W×L) | According to customer requirements | ||

Square Meters Per Roll | |||

Estimated Roll Weight | |||

It is widely used in Asphalt wall, railway foundation, dike slope, runway and sand harnessing.

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q: How about your company?

A:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q.Does your products have good qualitity?

A:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q:How long can we receive the products after purchase?

A:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: How do geogrids improve the performance of geocell-reinforced slopes?

- Geogrids improve the performance of geocell-reinforced slopes by providing additional tensile strength and stability to the structure. They help distribute the load more evenly, reducing stress on the geocells and preventing soil erosion. Geogrids also enhance the overall durability and longevity of the geocell-reinforced slopes, making them more resistant to deformation and settling.

- Q: Polyester warp knitted polyester geogrid and glass fiber geogrid price difference in the price of many components is a ghost?

- Different specifications and models can not compare the price, generally speaking, the same specifications, more expensive than glass fiber

- Q: What are the differences between geogrids and geopipes?

- Geogrids and geopipes are both geosynthetic materials used in civil engineering and construction projects, but they serve different purposes. Geogrids are typically made of high-strength polymers or metals and are used to reinforce soil, providing stability and enhancing load-bearing capacity. They are commonly used in applications such as retaining walls, slope stabilization, and road and pavement construction. Geogrids have an open structure with interlocking apertures, allowing soil particles to interlock with the material, creating a strong composite. On the other hand, geopipes are typically made of high-density polyethylene (HDPE) and are used for subsurface drainage and water management systems. They have a perforated or slotted design that allows for the efficient collection and transportation of excess water from the soil. Geopipes are commonly used in applications such as underdrains, French drains, and stormwater management systems. In summary, geogrids are used for soil reinforcement and stability, while geopipes are used for subsurface drainage and water management.

- Q: Which is the most suitable for Highway Subgrade

- We are specializing in the production of geogrid. The words are basically according to design drawings, but if you use it, most or two-way plastic and steel grating, durable plastic relatively longer, of course, the price is higher; two-way plastic instead.

- Q: Evaluation criteria and technical disclosure of geogrid.. Know how to share. Thank you

- 2) according to the design of the location, along the road to the laying of the grid, laying the grille, should pay attention to the connection between the grid and straightening smooth. Grille of the longitudinal and transverse joints can use nylon or polyester rope sewn or U nail connection method between the grid as a whole, grid overlapping width not less than 20cm, in the direction of the stress intensity of the joint shall not be less than the design tensile strength of materials. The grid distortion, fold, overlap, is not conducive to play its role, thus laying by hands straightened, the grid is smooth and uniform, geogrid every 1.5-2.0m paved with hook nail fixed on the ground.

- Q: What are the factors that affect the quality of glass fiber reinforced plastic grid

- The first is glass fiber. Glass steel fiber can improve the tensile strength and the elastic modulus of FRP pultruded grating plate, but also can reduce shrinkage, improve the heat deformation temperature and low temperature impact strength, therefore is glass steel grille pultrusion cover the main load-bearing part.

- Q: Can geogrids be used in reinforced soil slopes?

- Yes, geogrids can be used in reinforced soil slopes. Geogrids are commonly used in reinforced soil structures to enhance their stability and strength. They are placed within the soil layers to provide additional tensile strength and distribute the applied loads, thereby preventing slope failures and improving overall performance.

- Q: Are geogrids suitable for use in contaminated soil conditions?

- Yes, geogrids are suitable for use in contaminated soil conditions. Geogrids are made from durable materials like polyester or polypropylene, which are resistant to chemical degradation. They provide reinforcement and stabilization to the soil, preventing erosion and maintaining integrity even in contaminated environments. Additionally, geogrids can help with soil confinement, which reduces the spread of contaminants. Overall, geogrids are an effective solution for enhancing soil performance in contaminated soil conditions.

- Q: What are the typical properties and characteristics of geogrids?

- Geogrids are typically made of high-strength polymers or fiberglass materials and are used in civil engineering applications such as soil stabilization and reinforcement. They possess a high tensile strength, allowing them to distribute loads more effectively and improve the overall stability of the soil. Geogrids also exhibit excellent resistance against biological degradation, chemicals, and UV rays, ensuring their durability and long lifespan. They have a flexible and lightweight nature, making them easy to handle and install. Geogrids are known for their ability to improve soil confinement, prevent soil erosion, and enhance the performance of various construction projects.

- Q: How does a geogrid work?

- A geogrid works by providing reinforcement to soil or other materials. It is typically made of high-strength polymers or fibers arranged in a grid-like pattern. When placed within the soil, the geogrid interlocks with the surrounding particles, creating a stable network. This enhances the tensile strength and overall performance of the soil, preventing excessive movement, erosion, or failure. The geogrid redistributes applied loads, reducing stress concentrations and improving the stability and longevity of structures like retaining walls, roadways, and embankments.

Send your message to us

Neoloy Geocells Superior Quality Fiberglass Geogrid with Asphalt

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords