Geocells for Sale - Fiberglass Geogrid for Asphalt Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Used for Asphalt Reinforcement

Description Of Fiberglass Geogrid Used for Asphalt Reinforcement:

Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after surface covering own the favorable property of alkali resistance and aging resistance.

Main Features of Fiberglass Geogrid Used for Asphalt Reinforcement:

1.High tensile strength, low elongation.

2.No long-term creep: the product can keep for a long time performance.

3.Thermal stability: fiber glass melting temperature above 1000 ℃.

4.The compatibility with asphalt.

5.Physical and chemical stability.

Specifications of Fiberglass Geogrid Used for Asphalt Reinforcement:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid Used for Asphalt Reinforcement:

Strengthen bitumen concrete roadway and reduce and prevent various kinds of reflection gaps on roadway.

1.Suitable for highway, railway, airport road of subgrade enhancement.

2.Suitable for the large parking lot and port freight yard that the foundations of the permanent load increased.

3.Suitable for railway, highway slope protection.

4.Suitable for culverts.

5.Suitable for the uniaxial tensile geogrid reinforced soil secondary enhancement, after further enhance soil, prevent soil erosion.

6.Mining, tunnel reinforcement.

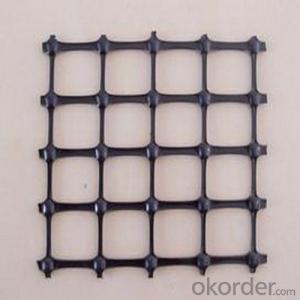

IMages of Fiberglass Geogrid Used for Asphalt Reinforcement:

FAQ of Fiberglass Geogrid Used for Asphalt Reinforcement:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: How do geogrids improve the performance of geogrid-reinforced earth walls?

- Geogrids improve the performance of geogrid-reinforced earth walls by providing tensile strength and stabilizing the soil, which helps to prevent the wall from sliding or collapsing. They distribute the forces exerted on the wall more evenly, reducing stress concentration and increasing overall stability. Additionally, geogrids enhance drainage and soil compaction, further enhancing the wall's performance.

- Q: Can geogrids be used in temporary construction access mats?

- Yes, geogrids can be used in temporary construction access mats. Geogrids are commonly employed in such mats to provide reinforcement and stability, making them suitable for heavy equipment and vehicle traffic during construction.

- Q: The amount of geotextile is estimated to be used on both sides of the retaining wall

- The use of the depth is greater than geotextile, geogrid generally in the 1-2 m or deeper in the use of the scope of the geotextile in general about 50CM

- Q: What are the long-term maintenance requirements for geogrid-reinforced structures?

- The long-term maintenance requirements for geogrid-reinforced structures typically involve periodic inspections to ensure the integrity and stability of the structure. This may include monitoring for signs of erosion, settlement, or damage to the geogrid or surrounding soil. Additionally, regular maintenance activities such as vegetation control, sediment removal, and drainage management may be necessary to prevent potential issues and ensure the long-term performance of the reinforced structure.

- Q: Can geogrids be used in stormwater detention systems?

- Yes, geogrids can be used in stormwater detention systems. Geogrids are often used to reinforce the soil and provide stability in these systems, helping to prevent erosion and maintain the structural integrity of the detention system.

- Q: What is the difference between Geogrid TGSG and GSL?

- TGSG is the national standard GB/T17689-2008 double plastic geogrid code

- Q: What are the factors to consider when selecting geogrids for a project?

- When selecting geogrids for a project, there are several factors to consider. These include the specific application or purpose of the project, the site conditions such as soil type and slope stability, the load requirements of the project, the desired lifespan and durability of the geogrids, and the cost-effectiveness and availability of the geogrids. Additionally, it is important to consider the installation process and compatibility with other materials used in the project. By considering these factors, you can ensure that the selected geogrids will effectively meet the needs of your project.

- Q: How do geogrids enhance the performance of geosynthetic clay liner capillary barriers?

- Geogrids enhance the performance of geosynthetic clay liner capillary barriers by providing additional reinforcement and stability to the liner. They help distribute loads more evenly, increase tensile strength, and reduce the potential for deformation or failure of the liner system. Additionally, geogrids assist in controlling lateral movement and prevent the loss of clay particles, ensuring better long-term performance and effectiveness of the capillary barrier.

- Q: Road overhaul of the original concrete pavement after washing asphalt paving, crack resistance is to use geotextile or geogrid

- Depends on the specific circumstances, the general use of grid

- Q: Can geogrids be used in geothermal energy systems?

- Yes, geogrids can be used in geothermal energy systems. Geogrids are commonly used in geothermal installations to reinforce the ground and provide stability for underground piping systems. They help distribute the weight and thermal load, reducing the risk of ground settlement and ensuring efficient heat transfer.

Send your message to us

Geocells for Sale - Fiberglass Geogrid for Asphalt Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords